Solid-State Batteries: The Next Revolution in Energy Storage

Solid-state batteries represent one of the most promising advancements in battery technology, poised to transform electric vehicles, consumer electronics, and renewable energy systems. By replacing flammable liquid electrolytes with solid materials, these batteries offer superior energy density, enhanced safety, faster charging, and longer lifespans compared to traditional lithium-ion cells.

How Solid-State Batteries Differ from Lithium-Ion

Traditional lithium-ion batteries rely on liquid or gel electrolytes to shuttle lithium ions between the anode and cathode. This design limits energy density due to safety concerns like thermal runaway and fire risk.

Solid-state batteries use ceramic, polymer, or sulfide-based solid electrolytes. This enables the use of lithium-metal anodes, which store far more energy than graphite. Key differences include:

- Energy density — Up to 500+ Wh/kg versus 250-300 Wh/kg in current lithium-ion packs.

- Safety — No flammable liquids, virtually eliminating fire risks.

- Charging speed — Many prototypes achieve 10-80% charge in under 15 minutes.

- Lifespan — Potential for thousands of cycles with minimal degradation.

- Temperature tolerance — Better performance in extreme cold or heat.

These improvements could enable EVs with 600-1,000+ mile ranges, 10-minute charging, and batteries that outlast the vehicle.

Key Advantages for Electric Vehicles and Beyond

For EVs, solid-state technology addresses major consumer barriers:

- Extended range → Packs with 400-500 Wh/kg could deliver 600-800 miles on a single charge in mid-size sedans.

- Rapid charging → High ionic conductivity in solid electrolytes supports ultra-fast rates without dendrite formation.

- Reduced weight and size → Higher volumetric density (up to 1,000+ Wh/L) means smaller, lighter packs for the same capacity.

- Enhanced safety → Solid electrolytes prevent leaks and thermal propagation.

- Lower long-term costs → Longer cycle life (potentially 40+ years in some designs) and reduced cooling needs.

Beyond EVs, applications include grid storage, drones, aerospace, and portable devices where safety and energy density are critical.

Major Challenges in Development

Despite progress, hurdles remain:

- Interface stability — Lithium dendrites can still form at solid-solid boundaries, causing shorts.

- Manufacturing scalability — High pressures and temperatures needed for solid electrolytes complicate mass production.

- Cost — Rare materials and new processes make early cells expensive.

- Ionic conductivity — Some solid electrolytes perform poorly at room temperature.

- Mechanical brittleness — Ceramic electrolytes can crack under stress.

Researchers are addressing these through hybrid electrolytes, protective coatings, and AI-optimized materials.

Leading Players and 2025 Breakthroughs

2025 marked a pivotal year with prototypes entering real-world testing and pilot lines scaling up.

Toyota

Toyota reaffirmed its 2027-2028 target for commercial solid-state batteries, claiming potential 40-year lifespans and 750+ mile ranges. Partnerships with Idemitsu Kosan and Sumitomo Metal Mining secured sulfide electrolyte supply chains.

QuantumScape

QuantumScape began shipping advanced B1 samples using its Cobra ceramic separator process. Cells achieved 844 Wh/L density and 12-minute fast charging. A Ducati motorcycle prototype demonstrated the technology, with Volkswagen's PowerCo licensing up to 80 GWh capacity.

Samsung SDI

Samsung SDI targets 2027 mass production with 900+ Wh/L density. In 2025, it joined BMW and Solid Power for validation, supplying cells with sulfide electrolytes for BMW test vehicles.

Factorial Energy

Partnered with Stellantis and Mercedes-Benz, Factorial validated 77Ah cells at 375 Wh/kg, enabling 18-minute charging and 749-mile real-world range in a Mercedes EQS prototype.

Other Notable Developments

- Nissan — Prototype cells doubled range potential; pilot line operational.

- Dongfeng (China) — 350 Wh/kg semi-solid batteries in testing, aiming for 1,000 km range by 2026.

- Solid Power — Supplied electrolytes to BMW/Samsung SDI; large-format cells in i7 prototypes.

- Chinese breakthroughs — New standards defined "true" all-solid-state batteries; fatigue mechanisms solved for longer life.

Academic advances from UC Riverside, UT Dallas, and others improved space charge layers and alloy anodes for better performance.

Current Status and Commercial Timeline

As of late 2025:

- Semi-solid-state batteries (hybrid designs) are in limited production (e.g., SAIC MG, Dongfeng).

- True all-solid-state prototypes are in automotive validation.

- Pilot lines operate at QuantumScape, Samsung SDI, Toyota, and Chinese firms.

- First commercial vehicles expected 2027-2029 (Toyota, Samsung SDI, Nissan).

- Demonstration fleets (Stellantis, Mercedes, BMW) launch in 2026.

Mass adoption likely begins 2030+, when costs approach lithium-ion parity.

Solid-state batteries are transitioning from lab curiosity to tangible reality. With energy densities doubling, charging times shrinking, and safety dramatically improved, they promise to accelerate EV adoption and enable new applications in energy storage. While full commercialization remains a few years away, 2025's milestones — from record-breaking prototype drives to scaled pilot production — confirm the technology is closer than ever. The race among Toyota, QuantumScape, Samsung SDI, and emerging Chinese leaders will determine who delivers the first game-changing products to market.

More from EV & Hybrid

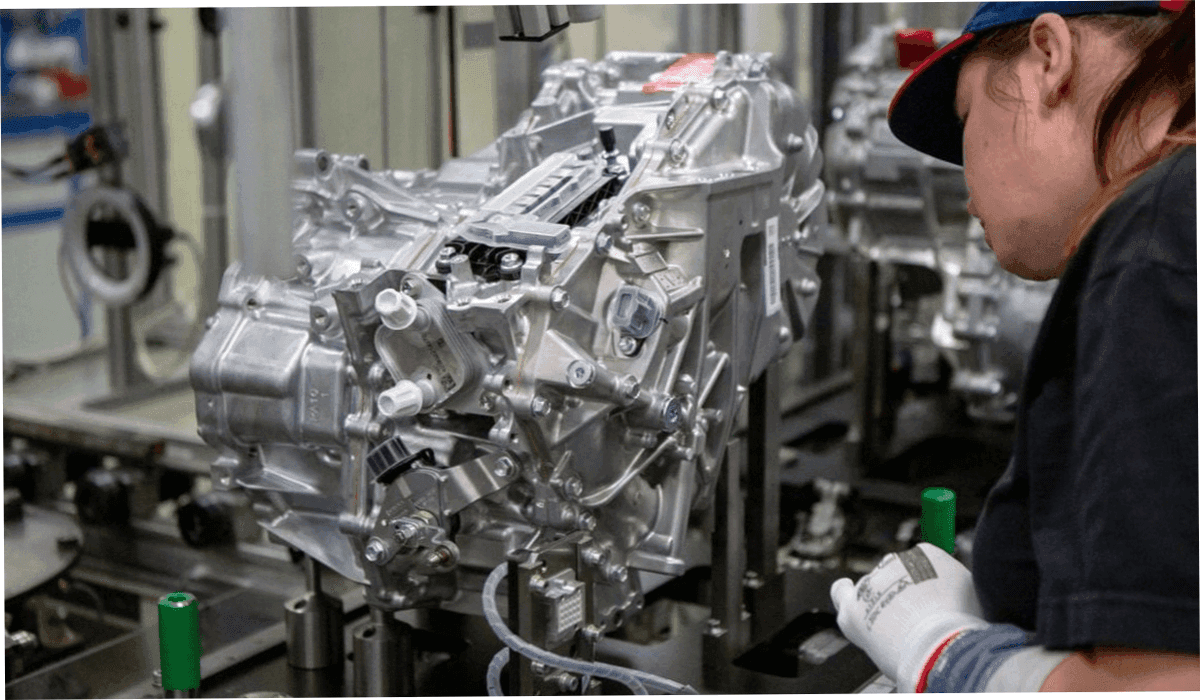

Toyota's 5th Generation Hybrid Powertrain: Revolutionizing Efficiency and Performance

25.11.2025 18:01

Tesla 4680 Second-Generation Batteries: Cybercell Breakthrough and 2025 Production Reality

20.11.2025 14:30