How to Permanently Fix F-150 Cam Phaser Rattle on 2017-2020 Models – Full DIY Guide

The infamous cam phaser rattle on 3.5L EcoBoost and 5.0L Coyote engines in 2017-2020 F-150 trucks is one of the most discussed issues among owners. The characteristic cold-start “diesel-like” or “marbles in a can” noise that lasts 1-3 seconds is caused by failed or failing cam phasers, worn timing chains, stretched chains, bad tensioners, and very often low oil pressure reaching the phasers at startup. This is a proven DIY repair that can be done in a weekend with basic to intermediate mechanical skills.

Understanding What Actually Causes the Cam Phaser Rattle

Cam phasers are variable valve timing actuators bolted to the end of each camshaft. Oil pressure pushes an internal spool valve and advances or retards cam timing. Inside each phaser is a locking pin that is supposed to hold the phaser in the full retard (base) position when the engine is off. When oil pressure is low or the internal springs weaken, the locking pin does not engage properly, allowing the phaser to “rattle” until oil pressure builds and locks it.

On 2017-2020 F-150s Ford used a revised but still problematic phaser design (part numbers ending in -AD, -AE, -AF). The factory phasers have weak return springs, poor oil filtration inside the phaser, and the locking pin mechanism wears quickly wears. Once one phaser starts rattling, the others usually follow within 10-20k miles.

Symptoms You Can’t Ignore

Loud rattle/marble noise for 1-4 seconds on cold start

Occasional rattle on hot restart if the truck sat for 20-60 minutes

Check Engine Light with codes P0011, P0016, P0021, P0022 (cam/crank correlation or over-advanced/over-retarded)

Slight loss of low-end torque and throttle response

Timing chain slap noise at 1500-2200 rpm under load (advanced stage)

Parts You Absolutely Need for a Permanent Fix

Skip the “rattle fix kits” with only lockout wedges. The only repair that lasts 100k+ miles is replacing all components:

4 × latest revision cam phasers (Ford ML3Z-6C525-B or Motorcraft equivalent – revision “AJ” or newer)

Complete timing chain kit: primary chain, secondary chains (2), guides (4), tensioners (2), crankshaft sprocket

VCT solenoids (4) – highly recommended to replace while everything is apart

Water pump (metal impeller version – the plastic impeller ones fail early)

Oil pump (Ford updated version with higher volume) – strongly recommended on 3.5L EcoBoost

Front crankshaft seal

Camshaft seals (4)

Valve cover gaskets (updated thicker design)

Motorcraft XO-5W30-QSP oil and Motorcraft FL-500S filter

New cam bolts (4) and crank bolt (torque-to-yield, one-time use)

Total parts cost: $900-$1300 depending on brand (genuine Ford vs aftermarket)

Tools Required for the Job

⅜” and ½” drive torque wrench

Cam phaser holding tool (OTC 6683 or Lisle 36880)

Cam phaser locking wedge tool set (essential for 2018+)

Crankshaft holding tool (OTC 6684 or Schley 13270)

Valve spring compressor (for 5.0L if you want to install lash adjusters/followers)

18mm, 15mm, 13mm, 10mm, 8mm wrenches and deep sockets

T70 Torx for water pump

Pick set and long magnets

Engine support bar or cherry picker

3-4 quarts of brake cleaner and plenty of shop towels

Step-by-Step Removal Process

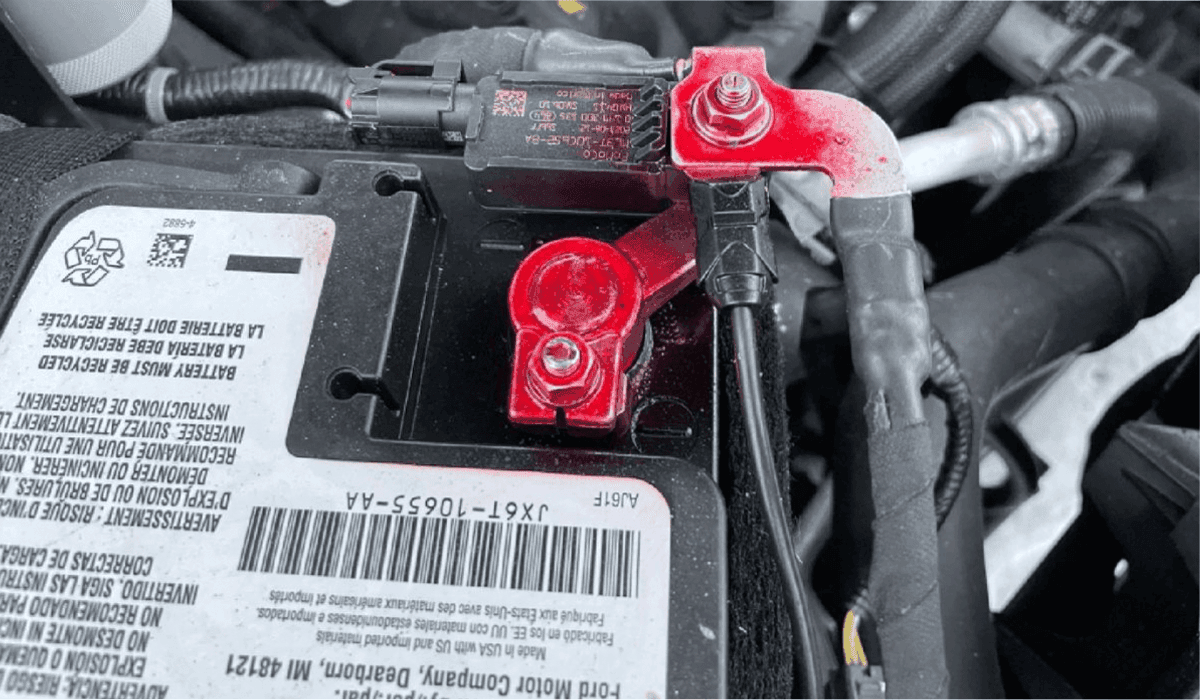

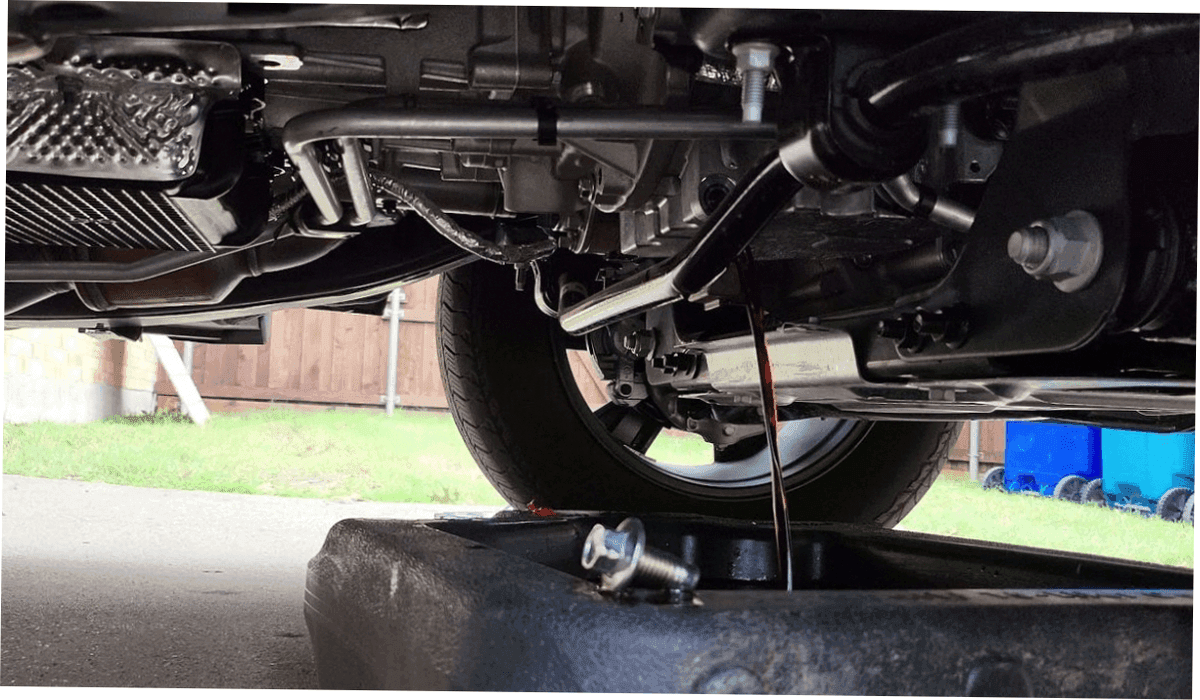

Disconnect battery, drain coolant and oil

Remove radiator fan shroud, fan clutch (left-hand thread), serpentine belt

Remove valve covers (mark all VCT solenoid connectors)

Remove power steering reservoir and bracket (3.5L)

Support engine with bar across the strut towers

Remove engine mount nuts, jack engine up 2-3 inches

Remove front engine cover (timing cover) – 24 bolts, be patient

Rotate engine to TDC #1 using crank bolt (clockwise only)

Install cam locking wedge tool between the two banks on 2018-2020 (mandatory)

Remove crank bolt, install holding tool

Remove tensioners, guides, chains, and old phasers (use phaser holding tool + 27mm wrench)

Critical Installation Tips That Prevent Comebacks

Clean every oil galley with brake cleaner and compressed air – the #1 cause of repeat failure is debris

Soak new phasers in oil for 30 minutes before installing

Apply clean oil to all chain guides and tensioner pads

New crank bolt: hand thread → 50 Nm → 90° → another 90°

New cam bolts: 40 Nm + 90°

On 2018-2020: install new style wedge plates that come with the updated phasers

Torque valve cover bolts in sequence: 5 Nm then 10 Nm

Prime oil system before first start: disable fuel and ignition, crank 15-20 seconds three times

First Start and Break-In Procedure

Fill with exactly 7.7 quarts (3.5L) or 8.8 quarts (5.0L) of Motorcraft 5W-30 synthetic blend

Turn key to ON for 30 seconds (to prime turbos on EcoBoost)

Start engine and immediately bring to 2500 rpm for 10 seconds (this locks phasers quickly)

Let idle for 15 minutes watching for leaks

Change oil and filter at 500 miles, then every 5,000 miles thereafter

Common Mistakes That Bring Trucks Back to the Shop

Reusing old VCT solenoids (screens clog → repeat rattle in 5k miles)

Not replacing both timing chain tensioners

Forgetting to install the small o-rings on the VCT solenoids

Over-torquing or under-torquing the crank bolt

Using aftermarket phasers that are still old “AD/AE” revision

Skipping the oil pump on high-mileage 3.5L EcoBoost (oil pressure drop is the root cause)

Expected Results After Proper Repair

Completely silent cold and hot starts

Noticeably better throttle response and low-end torque

Smoother idle

No more timing-related codes

Timing components good for another 150-200k miles with proper oil changes

This repair has been performed successfully by thousands of owners and independent shops. When done correctly with all updated parts, the cam phaser rattle is gone forever.

More from Ford

Ford F-150 Complete Maintenance Schedule: 2000 – Present (All Generations, Engines & Powertrains)

30.11.2025 12:32

How to Replace the Battery in a Ford F-150 (Any Year & Engine)

30.11.2025 04:04

How to Change Oil and Oil Filter on Ford F-150 (1990s to Present)

24.11.2025 14:03