Mustang GT 2018-2023 Oil Pump Gear Failure: DIY Inspection Guide

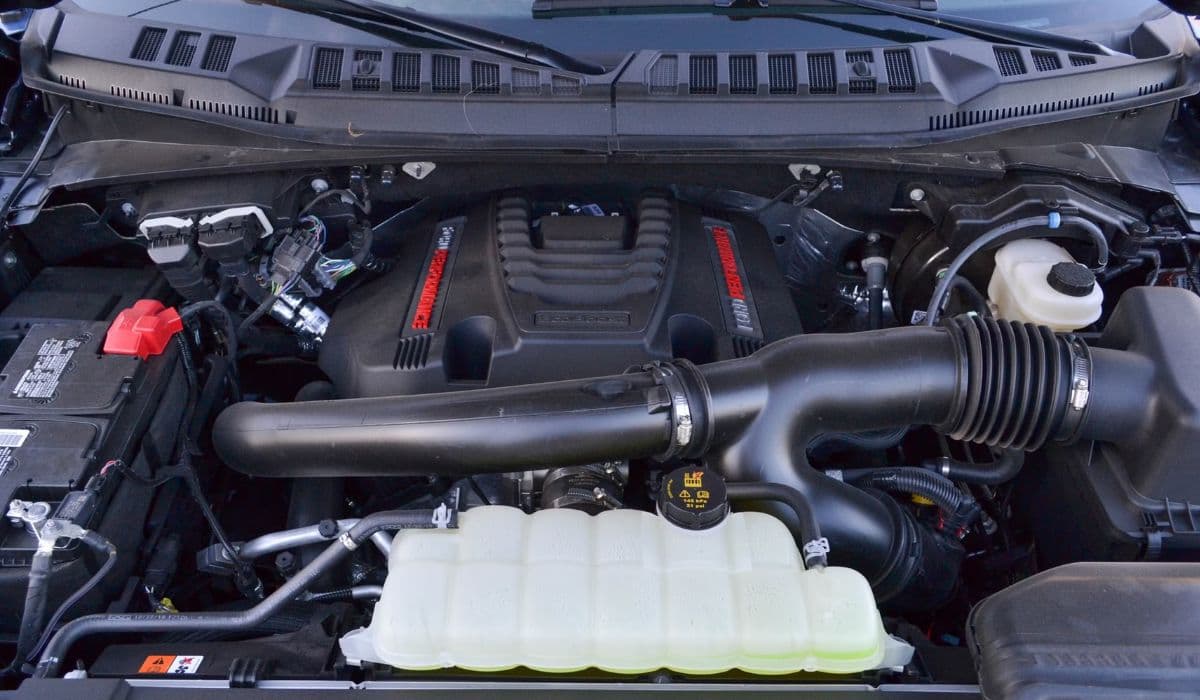

The 5.0L Coyote-powered Mustang GT (S550 facelift, model years 2018–2023) is widely regarded as one of the best modern muscle cars, but it carries a well-documented weakness: the factory sintered steel oil pump gear (OPG) can catastrophically delaminate, sending metal debris through the engine and often resulting in total engine loss. Ford never issued a recall, yet thousands of owners have experienced this failure, sometimes as early as 5,000 miles, sometimes past 100,000 miles, or even on cars that have sat for months. This guide explains exactly how to perform a thorough DIY inspection without dropping the oil pan or removing the timing cover — a procedure most owners can do in their driveway in under two hours.

Why the Oil Pump Gear Fails in Gen 3 and Gen 4 Coyote Engines

The root cause lies in the manufacturing process of the powdered-metal (sintered) oil pump gear. During production, the material is pressed and then brazed to a carrier plate in a high-temperature furnace using a copper brazing alloy. In a significant number of units, the copper braze joint is incomplete or porous. Over time (or very quickly in high-load situations), the gear begins to separate from the carrier. Once separation starts, the gear spins on the shaft, stops pumping oil effectively, and the loose pieces shatter, contaminating the entire engine. Oil pressure drops instantly, bearings spin, rods knock — game over.

Gen 3 (2018–2020) and Gen 4 (2021–2023) Coyotes use the exact same problematic part number (JR3Z-6600-A) despite Ford quietly switching to a stronger billet steel gear with improved brazing in late 2023 production and 2024+ models.

Symptoms That Usually Appear Before Catastrophic Failure

Most (but not all) owners report one or more of these warning signs days or weeks before total failure:

A new metallic “tick” or “marbles in a can” sound at idle that disappears above 1,200 rpm

Brief flickering of the oil pressure gauge on cold start or hot idle

Tiny bright flakes or copper-colored glitter visible on the oil dipstick or drain plug magnet

Slight drop in hot idle oil pressure (below 25–30 psi) compared to previous logs

Occasional single-cylinder misfire code (P030x) that clears itself

If you notice any of these, stop driving immediately and inspect.

Tools You Will Actually Need for a Proper DIY Inspection

8 mm, 10 mm, 13 mm, 15 mm wrenches and sockets

T30 Torx bit

Long magnetic pickup tool or flexible grabber

Bright LED flashlight or borescope (highly recommended)

Clean drain pan

6–7 quarts of fresh oil + new filter for refill

New oil pump pickup tube O-ring (Ford HL3Z-6622-A) — replace it while you’re in there

Nitrile gloves and plenty of shop towels

Step-by-Step: How to Visually Inspect the Oil Pump Gear Without Major Disassembly

Park on a level surface, let the engine cool completely (cold metal contracts and makes separation more visible).

Disconnect the battery negative terminal.

Remove the intake manifold (2018–2020 plastic or 2021–2023 composite). Yes, it sounds big, but it’s only 10 bolts + fuel line + vacuum lines and takes 30–45 minutes. Label everything.

Remove the plastic engine valley cover (held by four 8 mm bolts). Clean any oil out of the valley.

Remove the oil filter and oil filter adapter (13 mm socket). This gives you a straight shot down the pickup tube tunnel.

Using a long flexible borescope or a strong flashlight and mirror, look straight down the pickup tube passage toward the crankshaft. You will clearly see the back side of the oil pump gear and its carrier plate.

Rotate the engine by hand (24 mm socket on the crank bolt, clockwise only) through two full revolutions while watching the gear. A healthy gear shows zero movement between the sintered portion and the steel carrier.

Look for: – Visible copper braze line that appears cracked or missing in sections – Any radial play or wobble of the gear relative to the carrier – The gear “lifting” or separating when you stop cranking – Bright metal flakes stuck to the gear or inside the pickup tube

If you see any separation — even 0.5 mm — the gear is already failing and will grenade soon.

Alternative Inspection Method If You Don’t Want to Pull the Intake

For owners who refuse to remove the intake manifold, there is a secondary but less reliable method:

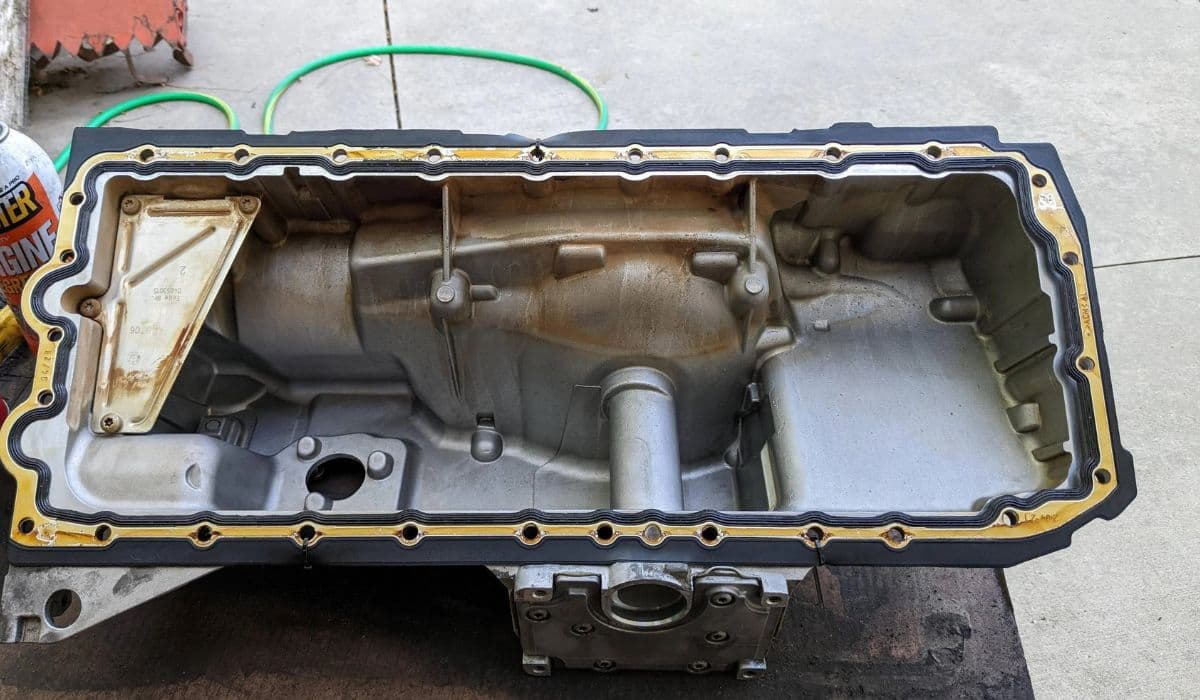

Drop the oil pan (yes, it’s more work, but still DIY-able with the car on jack stands).

Remove the oil pump pickup tube (two 10 mm bolts).

Remove the oil pump itself (three 13 mm bolts on the nose of the crank).

The gear is now in your hand. Inspect every tooth and the entire braze joint with a magnifying glass.

This method is 100 % conclusive, but requires new front cover gasket, pickup tube O-ring, and oil pan gasket.

What to Do If You Find a Failing or Suspect Gear

Replace it immediately with a known-good upgraded part. The current best options in order of popularity:

MMR billet steel oil pump gear set (direct drop-in, uses ARP bolt)

Boundary Pumps billet gear + high-flow pump assembly

Ford Performance 2024+ billet gear (M-6600-M52BILLET) — same as late factory fix

Livernois Motorsports or MPR billet gears

All of these eliminate the sintered gear entirely and are considered permanent fixes.

Torque Specs and Reassembly Tips You Don’t Want to Miss

Oil pump to block bolts: 18 ft-lbs (hand tighten in star pattern first)

Pickup tube to pump: 89 in-lbs

Pickup tube brace to main cap: 18 ft-lbs

Valley cover bolts: 89 in-lbs

Intake manifold bolts: 18 ft-lbs in the correct Ford sequence

Always use new O-rings and gaskets. Prime the new gear with assembly lube or clean oil before installation.

How Often Should You Re-Inspect If the Gear Looks Good Today

Even if your gear passes inspection, many owners re-check every 15,000–20,000 miles or every other oil change, because separation can begin suddenly. Once you’ve done it the first time, subsequent inspections take under 60 minutes.

Performing this inspection yourself can literally save a $15,000–$25,000 engine. The failure is not “if” but “when” on the factory sintered gear. Stay vigilant, inspect early, and upgrade before it costs you the entire motor.

More from Ford

How to Permanently Fix F-150 EcoBoost Gurgling Noise with the Condensation Drain Mod

08.12.2025 09:31

How to Fix Death Wobble on 2015-2023 Ford F-150 at Home – Real-World Permanent Solutions

08.12.2025 09:07

How to Delete Active Grill Shutters F-150

08.12.2025 09:13

Ford Explorer Police Interceptor Oil Pan Gasket Replacement: Complete Professional Guide

08.12.2025 06:21

H10R80 Transmission Fluid and Filter Change DIY – Complete Step-by-Step Guide for Ford 10-Speed Owners

08.12.2025 06:18