Ford Explorer Police Interceptor Oil Pan Gasket Replacement: Complete Professional Guide

The Ford Police Interceptor Utility, based on the Ford Explorer platform, is one of the most widely used pursuit-rated SUVs in North American law enforcement fleets. Its 3.3L, 3.0L EcoBoost, or 3.7L V6 powertrains endure extreme duty cycles, high-idle hours, and constant thermal stress, which dramatically accelerates oil pan gasket degradation. A leaking oil pan gasket on a Police Interceptor is far more common than on civilian Explorers and, if ignored, quickly leads to low oil pressure, contamination of brake components with oil, and catastrophic engine failure under pursuit conditions.

Why Police Interceptor Oil Pan Gaskets Fail Prematurely

The factory oil pan gasket on 2011–present Police Interceptor Utilities is a one-piece molded rubber design with integrated plastic carrier. Under police service the following factors combine to destroy it:

Prolonged idling at 1200–1500 rpm for hours (traffic control, K9 units, surveillance) creates extreme under-hood temperatures

Repeated cold-start/high-load cycles (code-3 responses) cause thermal expansion/contraction of the aluminum block and steel oil pan rails

Engine oil cooler and transmission cooler lines run directly above the pan, dripping hot fluid onto the gasket during minor seeps

Road salt and de-icing chemicals accelerate corrosion of the pan rail, breaking the gasket seal

Front impact bar and skid plate constantly transfer road shock to the pan

Most agencies see gasket seepage by 60,000–90,000 miles, and outright leakage by 120,000 miles.

Symptoms Specific to Police Package Vehicles

Oil drips concentrated on the passenger-side lower engine shield and front differential housing

Burning oil smell inside the cabin when the climate control is in fresh-air mode (oil hits the passenger-side catalytic converter first)

Oil accumulation inside the front skid plate and on the steering rack boots

Low oil pressure warning at hot idle after long idling shifts

Oil fouling the serpentine belt, causing chirp under acceleration

Required Tools and Materials

Ford-specific oil pan gasket (Motorcraft or OEM only – aftermarket pans have incorrect baffle design for police oil pickup)

Genuine Motorcraft XG-3-A silicone or updated Motorcraft TA-357 molded gasket (do NOT use RTV alone)

8 mm, 10 mm, 13 mm, 15 mm, 18 mm sockets and wrenches

T-55 and T-60 Torx for transmission-to-engine bolts

Engine support bar or cherry picker (mandatory – the engine must be lifted 2–3 inches)

Transmission jack with police-specific adapter plate

Long pry bar and large dead-blow hammer

M8×1.25 and M10×1.5 thread chaser taps (pan rails are almost always corroded)

Brake cleaner, Scotch-Brite red pads, plastic razor blades

6 quarts Motorcraft SAE 5W-30 Full Synthetic Blend + WIX 57502XP or Motorcraft FL-500S filter

Step-by-Step Removal Procedure (Police Interceptor Specific)

Raise vehicle on a two-post lift to full height. Remove belly pan, front skid plate, and transmission skid plate (four 15 mm bolts plus two T-55 Torx at the rear).

Drain engine oil and remove oil filter. Disconnect battery negative terminal (prevents accidental starter engagement when rotating engine).

Remove the front Y-pipe assembly. On 3.0L EcoBoost models, remove both catalytic converters completely (four 13 mm nuts per side plus O2 sensors). On 3.3L and 3.7L, the Y-pipe can stay attached to manifolds but must be dropped 6–8 inches.

Support the transmission with a jack and police adapter. Remove the four transmission mount nuts (18 mm) and the crossmember (four 18 mm bolts). Lower transmission 4–5 inches.

Install engine support bar across the fender lips and hook to the alternator bracket (driver side) and A/C compressor bracket (passenger side). Raise engine exactly 2.5 inches – no more, or the motor mounts will be damaged.

Remove the 18 oil pan bolts (8 mm and 10 mm) in reverse of the factory tightening sequence (outside-in spiral). Expect several bolts to snap – have M6×1.0 and M8×1.25 extraction kits ready.

Use a long pry bar between the pan and block at the rear corners. The pan will be glued with old silicone and corrosion. Strike the pry bar with a dead-blow – never pry against the transmission bellhousing.

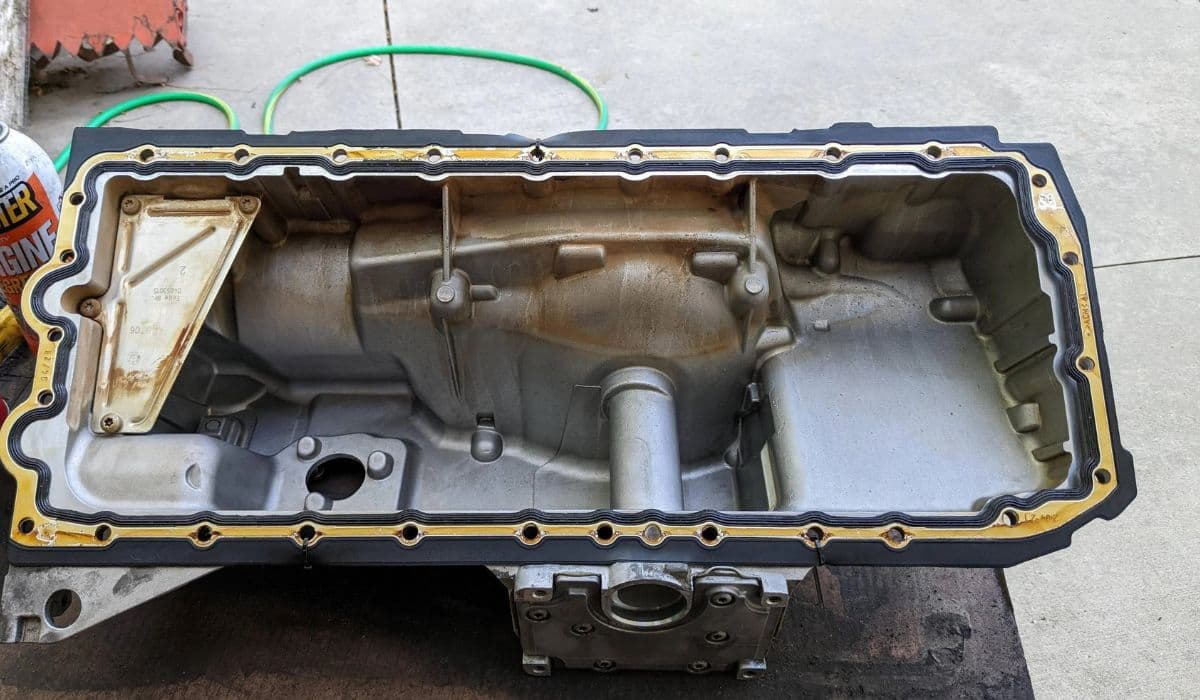

Once pan drops, immediately stuff clean rags around the pickup tube – police units have massive sludge buildup that will fall into the sump.

Critical Cleaning and Preparation

The aluminum block sealing surface is almost always pitted from salt corrosion. Chase every threaded hole with M8 and M10 taps. Use a die grinder with 80-grit Roloc disc to remove high spots, then finish with red Scotch-Brite until the surface is mirror-like. Any remaining old gasket material will cause immediate leakage under high-idle conditions.

Clean the pan rail with brake cleaner and plastic razor blades. Do not use metal scrapers – aluminum gouges create permanent leak paths.

Installation Differences for Police Interceptor

Apply a 3 mm bead of Motorcraft TA-31 (black RTV) only at the four corners where the timing cover and rear main seal retainer meet the block. Do NOT apply RTV along the entire rail – the molded gasket has built-in beads.

Install new gasket onto the pan (it snaps into the plastic carrier).

Raise pan into position and install two pilot bolts at the rear (closest to transmission) finger-tight.

Install remaining bolts finger-tight in factory sequence.

Torque all bolts in three stages: 5 Nm → 15 Nm → 25 Nm using the factory spiral pattern.

Lower engine and reinstall transmission crossmember and mount (torque to 90 ft-lb).

Reinstall Y-pipe using new gaskets and copper nuts (always replace – they seize).

Fill with exactly 6.0 quarts of Motorcraft 5W-30 and new filter. Prime the system by disabling fuel injectors (pull FI fuse) and crank for 15 seconds twice.

Common Mistakes That Cause Immediate Repeat Failure

Using gray RTV or aftermarket “high-temp” silicone instead of TA-357 gasket

Reusing stretched or corroded oil pan bolts

Failing to lift the engine – attempting to drop the pan with engine in stock position tears the gasket during installation

Not cleaning the block surface adequately (most shops just wipe with a rag)

Overtorquing bolts and warping the pan flange

Post-Repair Verification for Fleet Use

After 500 miles of mixed driving, re-torque all oil pan bolts to 25 Nm. Police units experience extreme vibration from light bar and partition equipment – bolts will loosen. Many agencies add Loctite 242 (blue) to the bolts during assembly for this reason.

A properly executed oil pan gasket replacement on a Police Interceptor Utility should last another 100,000+ miles even under severe duty.

More from Ford

How to Delete Active Grill Shutters F-150

08.12.2025 09:13

How to Remove Spark Plugs from a Ford 5.4L 3V Triton Without Breaking Them – Proven Step-by-Step Method

08.12.2025 08:58

How to Fix Death Wobble on 2015-2023 Ford F-150 at Home – Real-World Permanent Solutions

08.12.2025 09:07

How to Permanently Fix F-150 Cam Phaser Rattle on 2017-2020 Models – Full DIY Guide

08.12.2025 08:53

H10R80 Transmission Fluid and Filter Change DIY – Complete Step-by-Step Guide for Ford 10-Speed Owners

08.12.2025 06:18