How to fix crankcase ventilation (PCV) valve heater

BMW incorporated electric heating elements into the positive crankcase ventilation (PCV) system on certain engines to prevent ice formation in cold climates by warming vent hoses and valves. This feature appears prominently in N51, N52, and early N52KP naturally aspirated engines found in models like the E90/E91/E92 3 Series, E60 5 Series, and Z4 from approximately 2006-2013.

The heater integrates into the crankcase breather hose or elbow connector, drawing power from shared oxygen sensor circuits. Electrical shorts or stuck-on failures cause overheating without tripping main fuses, leading to melted components and potential engine bay fires. BMW issued multiple recalls (culminating in 22V-119) addressing this across hundreds of thousands of vehicles. Newer turbo engines like N20, N54, N55, and B58 lack this specific heater due to redesigned integrated PCV systems in valve covers.

Detecting Indicators of PCV Heater Malfunction

Early warnings include dashboard battery or charging alerts misattributed to related circuits, though primary risks manifest dramatically. Melting smells from the engine bay, visible smoke, or actual flames near the intake manifold signal acute overheating.

Check engine lights may accompany codes like P052B (cold start camshaft timing retarded, often coincidental post-repair) or P052E/P053A/P053C (PCV heater circuit open/high). Chronic issues produce burning plastic odors during cold operation. Visual inspection reveals deformed or charred breather hoses/elbow fittings at the valve cover rear.

Preparing Tools and Sourcing Reliable Replacement Parts

Diagnosis requires a BMW-compatible scanner for code retrieval and fuse checks. Basic tools include 10mm sockets, wire cutters/strippers for harness work, heat-shrink tubing, and dielectric grease.

Recall repairs involve a dealer-installed inline fuse kit (part 12 51 5 A6A 0E2) with wiring splice—free under safety recall. Independent fixes replace the blow-by heater elbow (around $50-100 genuine) and add component protection. Avoid reusing damaged harness sections; full kits ensure isolation from O2 heater circuits.

Confirming Involvement Through Targeted Testing

Scan for heater-specific or shared circuit codes. Inspect the breather hose/elbow for melting or resistance anomalies (healthy ~10-20 ohms cold).

Disconnect the heater connector temporarily—resolution of overheating risks confirms the component. Verify vehicle VIN eligibility on BMW or NHTSA sites for active recalls. Rule out unrelated PCV diaphragm failures causing whistles or oil consumption.

Accessing the PCV Heater Component

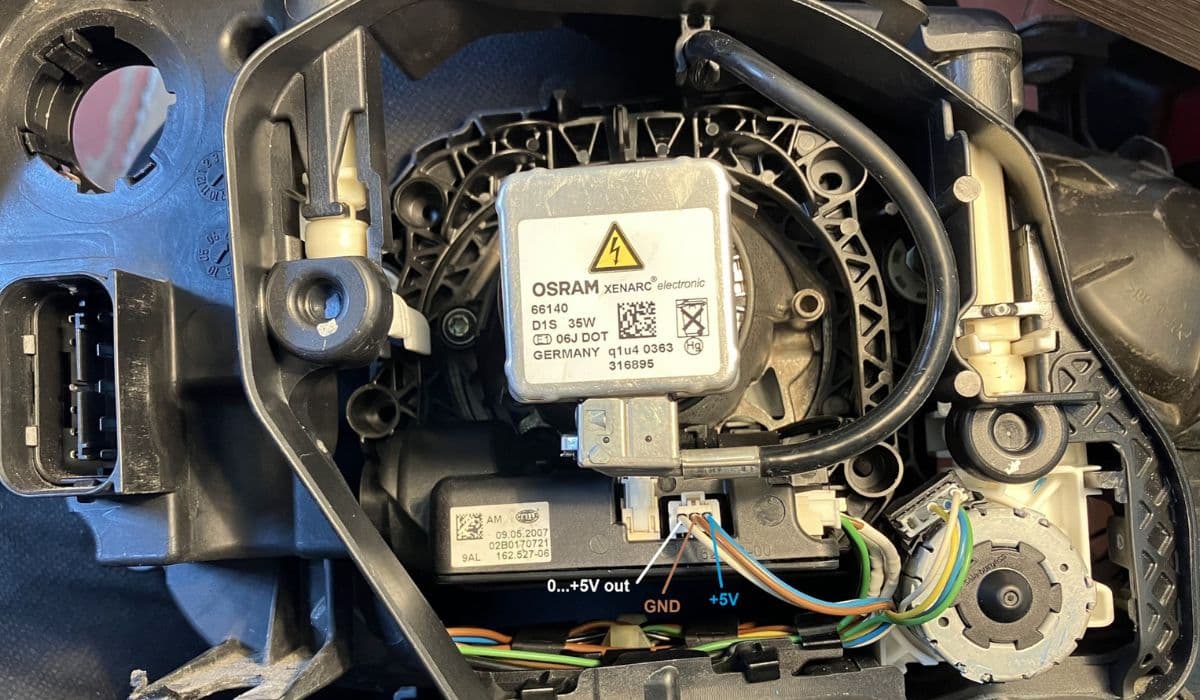

Work on a cooled engine in a well-ventilated area with fire extinguisher handy. Remove engine cover and intake ducting for clearance.

Locate the heated elbow or hose section routing from valve cover to intake—typically rearward on inline-six layouts. Disconnect electrical plug carefully, noting wire colors. Support adjacent hoses to prevent strain.

Removing the Faulty Heater Element or Hose

Trace the harness to the heater integration point. Cut damaged sections if melted, exposing wires for splicing.

Unclip or unscrew the elbow fitting—plastic threads strip easily, requiring gentle persuasion. Drain residual oil from hoses. Clean mating surfaces of carbon or residue.

Installing Updated Components and Circuit Protection

Insert the new elbow/heater, torquing gently to avoid cracking. Route replacement hose sections without kinks.

Per recall procedure, splice the inline fuse holder into the heater power wire—typically red/yellow tracer—ensuring weatherproof connections with heat-shrink. Secure harness away from heat sources. Genuine kits include revised wiring for reliable isolation.

Validating Functionality Post-Repair

Reconnect battery and clear codes. Monitor resistance and current draw via scanner.

Cold start test in low temperatures confirms no icing, while hot operation verifies no excessive heating. Drive cycles stabilize any adaptations. Recheck connections after 100 miles for security.

Sidestepping Common Complications in the Process

Incomplete harness isolation perpetuates short risks. Poor splicing invites water ingress and future failures.

Overtightening brittle plastic fittings necessitates full valve cover consideration. Overlooking recall eligibility delays free professional remediation. Adjacent O2 sensor damage from prior melting requires concurrent checks.

Promoting Long-Term PCV System Reliability

Prevention emphasizes recall compliance—dealers perform fuse retrofits reliably. Maintain clean oil with frequent changes to minimize vapor loading.

Inspect breather lines during services for early deformation. Avoid cold-weather block heaters stressing shared circuits. For non-recall engines, integrated designs eliminate this vulnerability entirely. Proactive monitoring safeguards against rare but severe thermal events in affected generations.

More from BMW

How to fix charge pipe failure on tuned M3/M4

13.12.2025 18:49

How to fix FRM footwell module lighting issues

13.12.2025 14:40

How to replace control arm bushings (front thrust arms)

13.12.2025 18:55

How to replace transfer case actuator (xDrive grinding noise)

13.12.2025 14:45

How to fix adaptive headlight malfunction (AHL errors)

13.12.2025 19:00