Ford EcoBoost: Turbo Coolant Line Inspection and Replacement Tips

Ford's EcoBoost engines revolutionized automotive performance by blending turbocharging with direct fuel injection, delivering impressive power from smaller displacements. At the heart of this system lies the turbo coolant line, a critical component that circulates coolant to prevent overheating in the turbocharger. This line ensures the turbo remains at optimal temperatures, especially during high-boost scenarios like highway merging or towing heavy loads.

Imagine pushing your Ford F-150 or Mustang through a demanding drive; without proper cooling, the turbo could warp or fail prematurely, leading to costly downtime. The coolant line, often made from durable rubber or braided steel, connects the engine's cooling system to the turbo housing. Over time, exposure to extreme heat cycles and vibrations can degrade it, making regular checks essential for longevity.

What sets EcoBoost apart is its water-cooled turbo design, which enhances efficiency by reducing lag and improving throttle response. However, this sophistication demands vigilance. A compromised line might leak coolant, causing the engine to overheat or the turbo to seize, turning a thrilling ride into a roadside headache.

Signs of a Failing Turbo Coolant Line

Spotting issues early can save your engine from major damage. EcoBoost owners often overlook subtle warnings until they escalate.

Coolant leaks under the vehicle, especially near the turbo area, appearing as greenish or pinkish puddles.

Unusual engine overheating, even during moderate driving, indicated by rising temperature gauges.

White smoke from the exhaust, signaling coolant entering the combustion chamber via a breached line.

Reduced boost pressure, making acceleration feel sluggish, as if the turbo is underperforming.

Hissing sounds from the engine bay, suggesting pressurized coolant escaping through cracks.

These symptoms aren't always dramatic; sometimes, it's a faint odor of burning coolant or minor power dips that hint at trouble. In real-world cases, like on long trips through mountainous terrain, a failing line could trigger limp mode, limiting your speed and stranding you far from help.

Tools and Materials Needed for Inspection and Replacement

Preparing the right gear streamlines the process, turning a potentially frustrating task into a manageable one. Focus on quality tools to avoid stripping bolts or causing further damage.

For inspection:

Flashlight or shop light to illuminate tight spaces.

Mirror on a stick for viewing hard-to-reach areas.

Rags and a drip pan to catch any spills.

Basic socket set for accessing clamps.

For replacement:

New OEM or equivalent turbo coolant line specific to your EcoBoost model.

Hose clamps if not included with the line.

Coolant compatible with Ford specifications.

Pliers and wrenches for secure fittings.

Torque wrench to ensure proper tightening without over-stressing components.

Having these on hand not only speeds things up but also builds confidence, especially for DIY enthusiasts tackling this in a home garage.

Step-by-Step Inspection Guide

Begin with safety: park on level ground, let the engine cool completely, and disconnect the battery to prevent accidental starts.

Locate the turbo coolant line – typically running from the coolant reservoir or radiator to the turbocharger, often on the passenger side in models like the Focus ST or Explorer.

Visually scan for obvious damage: look for cracks, bulges, or wet spots indicating leaks. Use your mirror to check underside connections.

Feel along the line with gloves on; softness or brittleness suggests degradation from heat exposure.

Check fittings and clamps for looseness; gently tug to test security without forcing.

Start the engine and observe for drips or steam while monitoring the temperature gauge.

This methodical approach uncovers hidden issues, like micro-cracks that only appear under pressure. For instance, in older EcoBoost variants, lines near exhaust manifolds wear faster due to radiant heat.

Detailed Replacement Procedure

If inspection reveals problems, replacement is straightforward but requires patience to avoid complications.

Drain the coolant system first by opening the petcock or removing the lower radiator hose, collecting fluid in a pan for proper disposal.

Remove the old line: loosen clamps with pliers, carefully disconnect fittings, and wiggle the line free. Note any brackets or routing paths for reinstallation.

Install the new line: align it precisely, secure with fresh clamps, and torque to manufacturer specs to prevent leaks.

Refill with coolant, bleed air from the system by running the engine with the cap off, and top up as needed.

Test drive afterward, watching for leaks or abnormal temperatures. This process, when done right, restores peak performance, as seen in tuned EcoBoost setups where reliable cooling supports higher boost levels.

Common pitfalls include overtightening, which cracks plastic fittings, or skipping the bleed step, leading to air pockets and hotspots.

Maintenance Tips to Prevent Turbo Coolant Line Issues

Proactive care extends the life of your EcoBoost's cooling system, ensuring reliability across seasons.

Schedule regular coolant flushes every 30,000 miles to remove contaminants that accelerate line wear.

Use only Ford-approved coolant to avoid chemical reactions that degrade rubber components.

Inspect during oil changes; it's a quick add-on that catches issues early.

Avoid aggressive driving immediately after cold starts; let the system warm up to reduce thermal shock.

Consider upgrading to reinforced lines for high-mileage vehicles or those in extreme climates.

By integrating these habits, owners report fewer breakdowns, maintaining that signature EcoBoost punch for years. Think of it as investing in the thrill of turbocharged driving without the worry.

More from Ford

Ford F-150: Active Grille Shutter Maintenance and Cleaning Guide

28.12.2025 11:29

Ford Maverick Hybrid: Battery Cooling Fan Cleaning Tips

28.12.2025 08:22

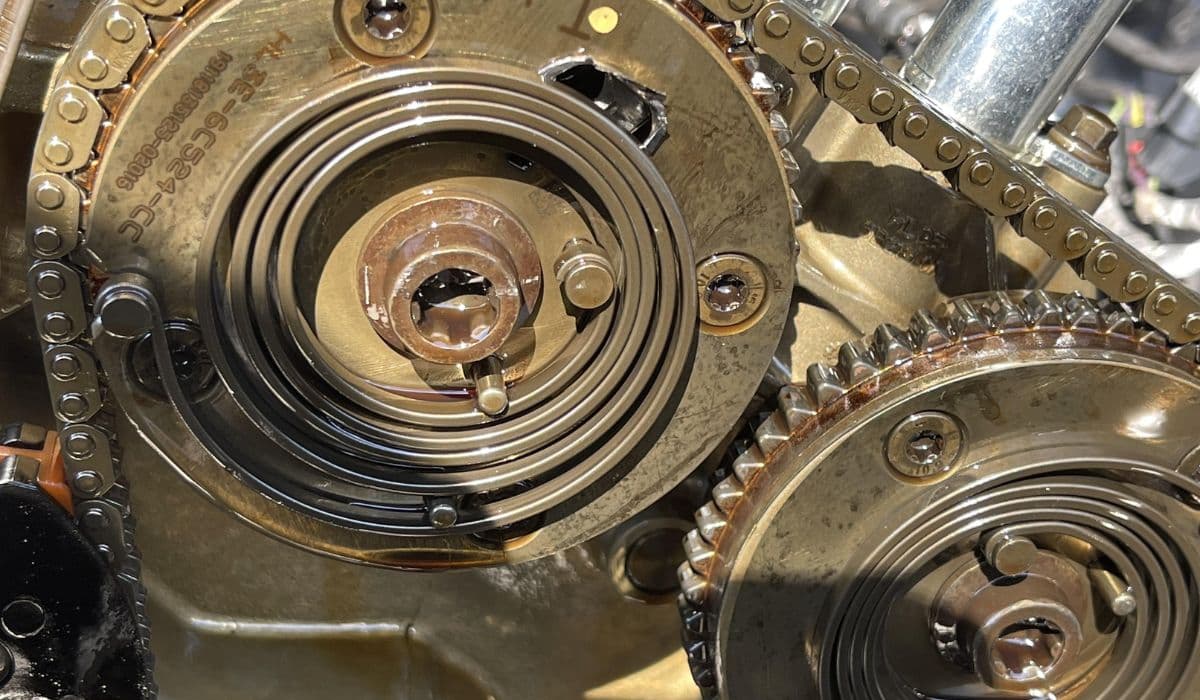

Ford EcoBoost: Preventing Cam Phaser Rattle with Regular Oil Changes

28.12.2025 05:53

Ford F-150: Oil Change Interval Guide for EcoBoost Engines

27.12.2025 17:14

Ford F-150: How to Perform Tire Rotation and Balance Every 5,000 Miles

27.12.2025 14:45