Ford EcoBoost: Preventing Cam Phaser Rattle with Regular Oil Changes

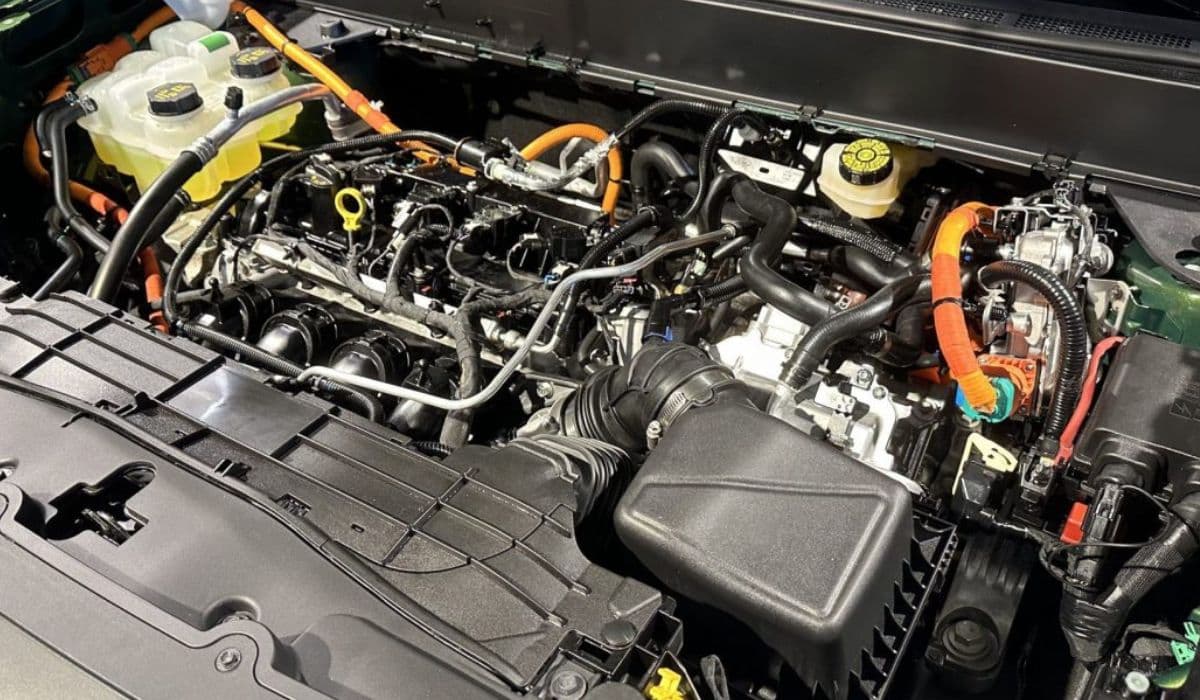

Ford's EcoBoost engines represent a pinnacle of modern automotive engineering, blending turbocharging with direct injection to deliver impressive power from smaller displacements. These powerplants, found in models like the F-150, Mustang, and Explorer, prioritize efficiency without sacrificing performance. However, like any sophisticated system, they have their vulnerabilities. One common issue that plagues EcoBoost owners is cam phaser rattle—a metallic clattering noise that often emerges during cold starts or at low RPMs.

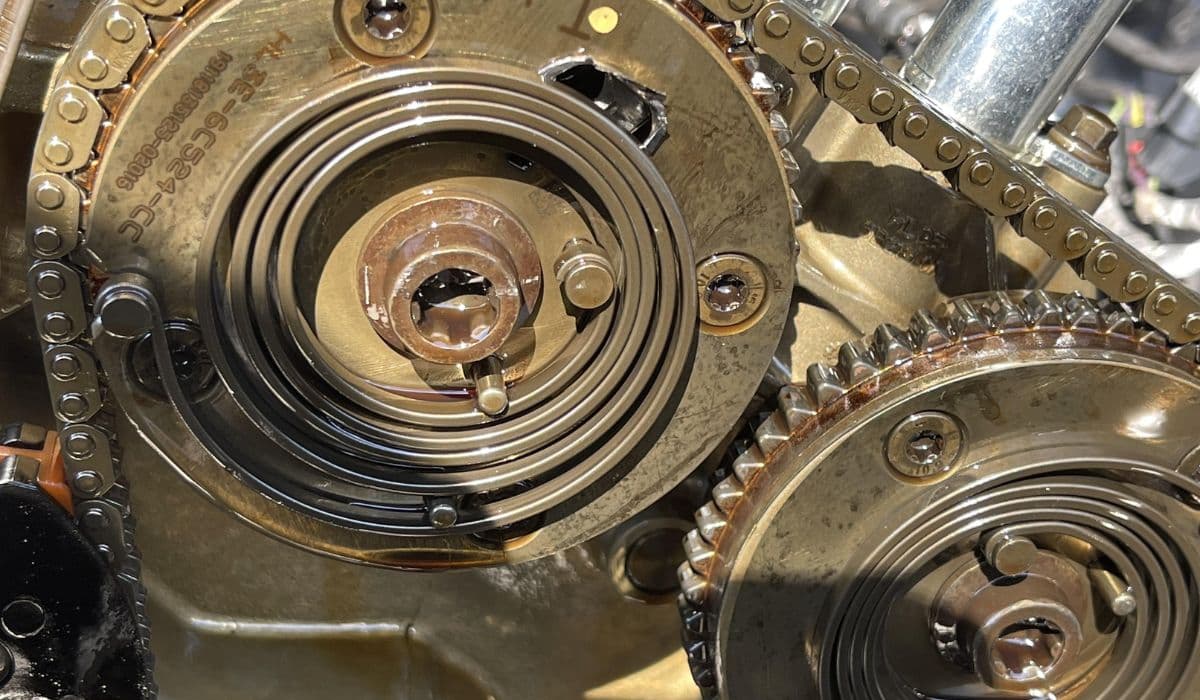

Cam phasers are variable valve timing components that adjust the timing of the intake and exhaust valves for optimal engine operation across various speeds and loads. In EcoBoost engines, they rely on hydraulic pressure from engine oil to function smoothly. When this system falters, the phasers can produce a distinctive rattle, reminiscent of a loose chain or marbles in a can. This isn't just an annoyance; it signals potential wear that could lead to reduced engine efficiency or, in severe cases, more extensive damage.

What causes this rattle? Primarily, it's linked to oil degradation or insufficient lubrication. Over time, engine oil breaks down due to heat, contaminants, and shear forces, losing its viscosity and ability to maintain consistent pressure. In high-stress EcoBoost environments, where turbochargers push temperatures higher, this degradation accelerates. Sludge buildup or varnish on the phasers can also restrict oil flow, exacerbating the problem. Interestingly, this issue has been more pronounced in certain EcoBoost variants, like the 3.5L V6, where the dual overhead cam setup amplifies the demands on the timing system.

The Role of Engine Oil in Cam Phaser Functionality

Engine oil isn't just a lubricant; it's the lifeblood of your EcoBoost's variable valve timing system. Cam phasers operate using oil pressure to advance or retard valve timing, ensuring the engine breathes efficiently for power and fuel economy. When oil is fresh and at the right specification, it provides the hydraulic cushion needed to dampen vibrations and prevent metal-on-metal contact within the phaser assembly.

Ford specifies synthetic oils meeting WSS-M2C913-D or similar standards for EcoBoost engines, emphasizing low-viscosity formulations like 5W-30 to flow quickly during startups. These oils contain additives that combat oxidation, reduce foaming, and maintain film strength under turbo-induced heat. Without proper oil, the phasers can lock up or oscillate erratically, leading to that telltale rattle.

Consider the phaser's internal workings: solenoid valves direct oil into chambers that shift the camshaft position. If oil thickens or clogs these passages, pressure drops, allowing the phaser's internal components to slap against each other. This is why maintaining oil quality is crucial—it's not merely about mileage intervals but about preserving the fluid's chemical integrity in a demanding turbocharged setup.

Signs and Symptoms of Cam Phaser Issues

Recognizing cam phaser rattle early can save EcoBoost owners from headaches down the road. The most obvious symptom is a rattling or ticking sound from the front of the engine, especially noticeable during the first few seconds after starting a cold engine. It might fade as the oil warms and pressure builds, but ignoring it allows wear to progress.

Other indicators include:

Rough idling or hesitation during acceleration, as valve timing drifts out of sync.

Reduced fuel efficiency, since improper timing affects combustion completeness.

Check engine light illumination, often with codes like P0011 or P0014 related to camshaft position.

In advanced stages, a noticeable loss of power, particularly in the low-RPM range where EcoBoost shines for torque.

These symptoms aren't unique to phaser problems, but in EcoBoost engines, they're frequently tied to oil-related neglect. Drivers often describe the noise as intermittent, worsening in colder weather when oil is thicker and slower to circulate. Paying attention to these cues transforms routine maintenance into proactive care, keeping your Ford running like new.

How Regular Oil Changes Prevent Rattle

The simplest defense against cam phaser rattle is a disciplined oil change regimen. Fresh oil restores the hydraulic properties essential for phaser stability, flushing out contaminants that could gum up the system. In EcoBoost engines, where heat from the turbo can degrade oil faster, sticking to or even shortening manufacturer-recommended intervals pays dividends.

During an oil change, old fluid is drained, removing particulates from combustion byproducts and metal wear. A new filter ensures clean oil circulates, maintaining consistent pressure to the phasers. This process also replenishes additives that protect against corrosion and thermal breakdown, directly countering the factors that lead to rattle.

Real-world experiences from EcoBoost enthusiasts highlight the difference: those who change oil every 5,000 miles report fewer issues compared to those stretching to 10,000. It's about quality over quantity—using the right synthetic blend ensures the oil withstands the rigors of boosted performance. By preventing sludge accumulation, regular changes keep oil passages clear, allowing phasers to operate without the vibrations that cause noise and wear.

Best Practices for Oil Maintenance in EcoBoost Engines

To maximize the benefits, adopt a holistic approach to oil care. Start by monitoring oil levels regularly, as low oil can starve the phasers of pressure. Use a dipstick check weekly, especially if your driving involves frequent short trips that don't allow full warm-up.

When selecting oil, prioritize those with robust detergent packages to combat carbon deposits from direct injection. Warm up the engine gently in cold conditions to aid oil flow, reducing startup stress on phasers.

Incorporate these habits:

Schedule changes based on driving conditions—severe duty like towing or stop-and-go traffic warrants more frequent service.

Inspect for leaks during changes, as even minor ones can lead to pressure loss.

Consider oil analysis kits to gauge degradation levels, providing data-driven insights into your engine's health.

Pair oil changes with filter replacements to avoid reintroducing contaminants.

By embedding these practices, EcoBoost owners not only sidestep rattle but also enhance overall longevity. The engine's responsive turbo spool and seamless power delivery remain intact, turning every drive into a testament to thoughtful maintenance.

More from Ford

Ford F-150: Oil Change Interval Guide for EcoBoost Engines

27.12.2025 17:14

Ford F-150: How to Perform Tire Rotation and Balance Every 5,000 Miles

27.12.2025 14:45

Ford 6.7L Powerstroke CP4 Pump Failure Prevention: Complete In-Depth Guide

08.12.2025 06:53

2022-2025 Ford Maverick Hybrid Battery Cooling Mod: The Ultimate Performance and Longevity Upgrade

08.12.2025 06:50

F-150 3.5 EcoBoost Spark Plug & Coil Replacement DIY: Complete Step-by-Step Guide

08.12.2025 06:44