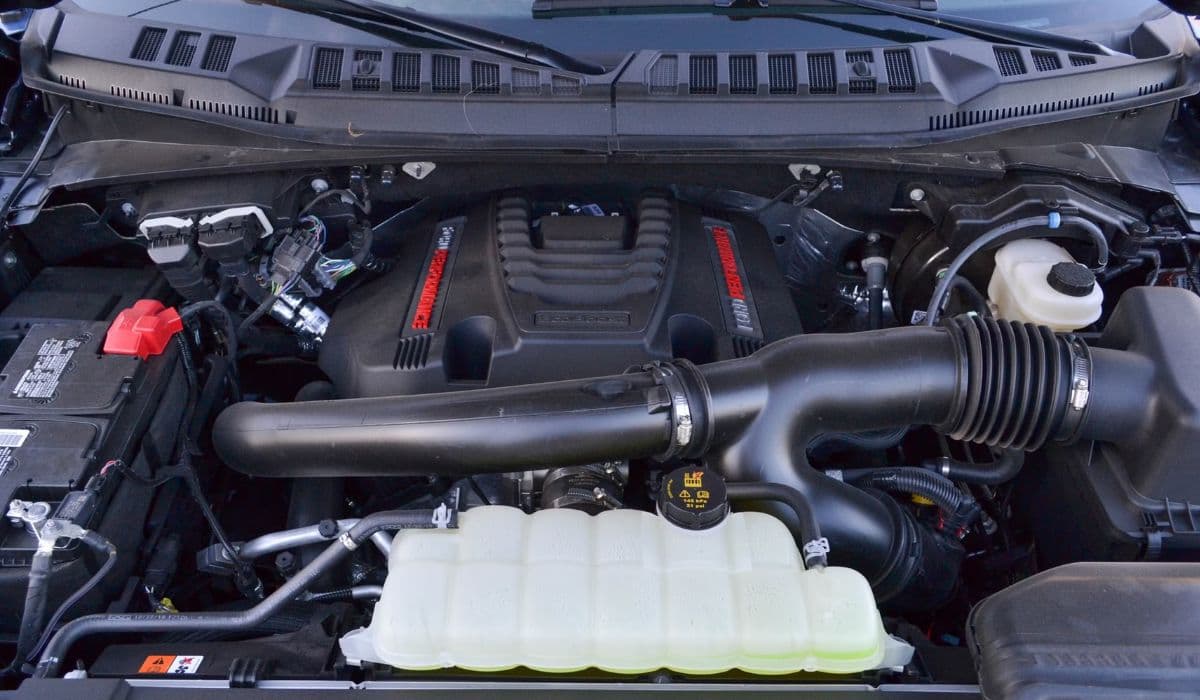

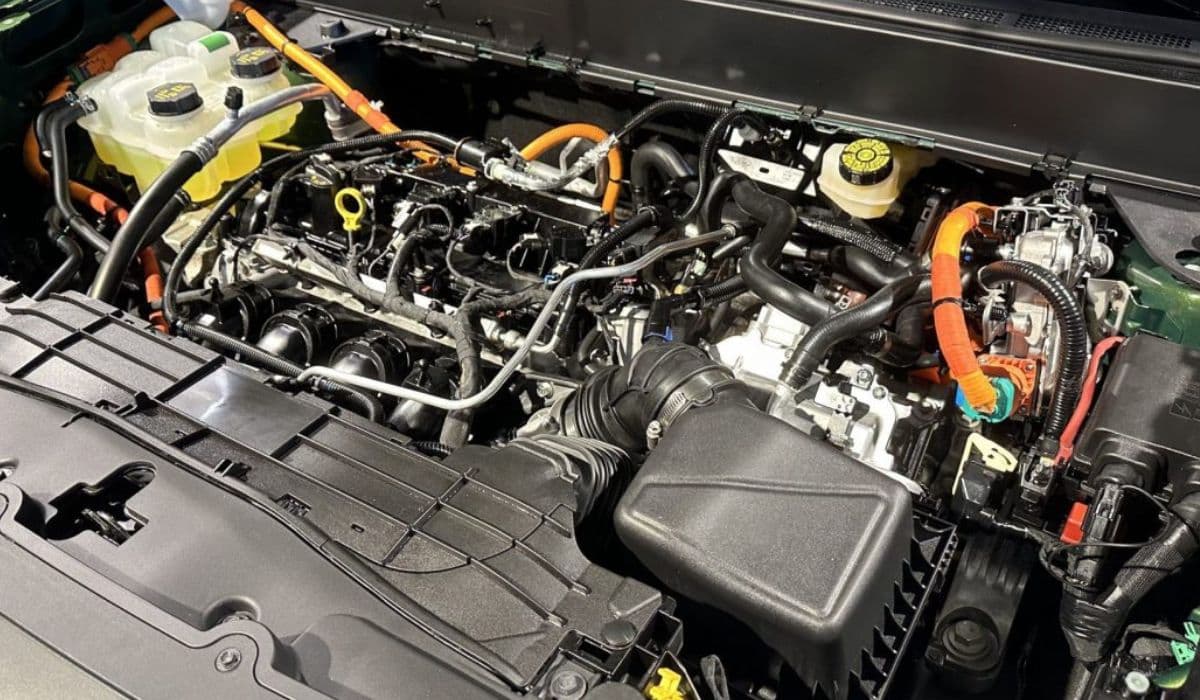

Ford 6.7L Powerstroke CP4 Pump Failure Prevention: Complete In-Depth Guide

The Bosch CP4 high-pressure fuel pump used in the 2011–present Ford 6.7L Powerstroke is widely regarded as the single most catastrophic weak point in an otherwise extremely durable engine. When the CP4 fails, it typically sends metal shavings through the entire fuel system, often resulting in a total fuel system replacement that can easily exceed $10,000–$15,000. This article covers every proven and field-tested method to dramatically reduce the risk of CP4 failure and protect your investment.

Understanding Why the CP4 Pump Fails in the 6.7L Powerstroke

The CP4.2 (Bosch part 0445020043 and later revisions) is a two-piston radial pump designed for European diesel specifications that assume excellent fuel lubricity and extremely low water content. U.S. ultra-low-sulfur diesel (ULSD) has far lower lubricity than European EN 590 diesel, and the CP4 has almost zero tolerance for contamination or lubrication breakdown.

Primary failure modes:

Internal roller lifter and cam wear caused by marginal lubricity

Scoring of pistons and barrel due to metal-to-metal contact

Catastrophic seizure when even microscopic water or dirt enters the pump

Rapid disintegration once initial wear begins, sending aluminum and steel particles downstream to injectors, rails, lines, and return system

Once the pump grenades, the only reliable fix is complete fuel system replacement. There is no safe “flush and replace pump only” option.

Fuel Quality – The Single Biggest Preventable Factor

Poor diesel quality is involved in the majority of documented CP4 failures.

Always buy fuel from high-volume stations (truck stops preferred)

Avoid “off-brand” or low-turnover stations where water and sediment accumulate

Never purchase fuel immediately after a tanker delivery (stirs up tank sediment)

In cold climates, insist on winterized or #1 diesel to prevent gelling and water separation

Consider carrying a Mr. Funnel or similar water-separating filter funnel for suspect fuel

Lubricity Additives – Mandatory Protection for Every Tank

Every reputable 6.7L Powerstroke owner and diesel performance shop runs a lubricity additive at every fill-up. The most proven products that consistently pass the HFRR (High Frequency Reciprocating Rig) scar diameter test below 460 µm (ASTM D6079) include:

Opti-Lube XPD and Opti-Lube Summer/Winter blends

Hot Shot’s Secret Diesel Extreme and FR3 Friction Reducer

Stanadyne Performance Formula and Lubricity Formula

Archoil AR6500 Diesel Treatment

Power Service Diesel Kleen + Cetane Boost (silver bottle)

Dosage: Follow the “treat rate for poor lubricity” on the bottle (typically double the maintenance dose). Many owners treat at 1 oz per 5 gallons year-round.

Water Separation – The Silent CP4 Killer

Water in diesel fuel instantly destroys the CP4’s hardened internal surfaces.

Best practices:

Replace the under-hood factory water-separator filter (Motorcraft FD-4615 or Baldwin PF46152) every 10,000–15,000 miles or annually

Install an aftermarket pre-pump water separator such as FASS Fuel Systems Water Separator (WS1002) or AirDog Water Separator

Add a biocide (Power Service Bio Kleen, Stanadyne, or DieselCraft) at every fill-up in humid climates or if the truck sits for weeks

Lift Pump Upgrades – The Most Effective Single Modification

The factory in-tank lift pump delivers only 8–12 psi to the CP4 at high demand. The CP4 was never designed to pull fuel; it expects 70–100 psi of clean, constant supply pressure.

Installing a quality lift pump system is the #1 recommended upgrade by every major 6.7L specialist:

Top proven systems:

FASS Titanium Signature Series (95–125 gph)

AirDog II-4G or 5G (100–165 gph)

Fuelab Prodigy

PureFlow AirDog Raptor (if keeping factory filter location)

Benefits beyond CP4 protection:

Removes 99 % of water, air, and debris before it supplies regulated pressure

Lowers fuel temperatures

Increases injector life and consistency

Disaster Prevention Kits and Bypass Solutions

Several companies now offer “CP4 bypass” or “disaster prevention” kits that route fuel around the CP4 in the event of failure, preventing metal contamination downstream.

Most popular:

S&S Diesel Motorsport CP4 Bypass Kit (most installed)

Exergy Performance CP4 Disaster Prevention Kit

DieselSite Adrenaline HPOP (completely eliminates CP4 by reverting to 7.3L-style HEUI system – expensive but bulletproof)

These kits do not prevent the pump from failing, but they save the rest of the $12,000 fuel system.

Monitoring Tools Every 6.7L Owner Should Have

Early detection can sometimes allow pump replacement before total failure.

Essential monitoring:

Edge Insight CTS3 or Torque Pro with fuel rail pressure PID monitoring (watch for sudden drops or erratic readings)

Fuel filter minders – replace immediately when vacuum exceeds 8 inHg

Regular used-oil analysis (Blackstone Labs) – watch for rising aluminum and iron if pump is beginning to wear

Maintenance Schedule for Maximum CP4 Longevity

Fuel filter set (both filters) every 15,000 miles or 12 months max

Lift pump filter (if equipped) every 30,000 miles

Lubricity additive at every single fill-up without exception

Water drain from factory separator monthly

Air filter replacement every 20,000 miles (dirty air filter = higher crankcase pressure = fuel dilution)

Cold Weather Specific Precautions

The CP4 is especially vulnerable below 20 °F:

Keep battery voltage above 12.6 V (weak batteries cause low cranking RPM and poor initial lubrication)

Use winterized fuel or anti-gel additive

Plug in the block heater below 15 °F

Cycle the key 3–4 times before cranking to build lift-pump pressure

What to Do If You Suspect CP4 Failure

Symptoms: long crank, white smoke, surging, P0087 or P0088 codes, metal in fuel filter.

Immediate actions:

Do NOT continue driving

Tow the truck

Order a disaster prevention kit if not already installed

Budget for full fuel system replacement unless a bypass kit is present

The CP4 pump in the Ford 6.7L Powerstroke can be managed to achieve reliable service life, but only with religious attention to fuel quality, mandatory lubricity additives, upgraded filtration, and ideally a proper lift pump system. Owners who follow every recommendation above routinely see 250,000–400,000+ miles without CP4-related catastrophes.

More from Ford

How to Permanently Fix F-150 EcoBoost Gurgling Noise with the Condensation Drain Mod

08.12.2025 09:31

How to Change Rear Differential Fluid on 2020-2024 Ford Explorer (6th Generation) – Complete Step-by-Step Guide

08.12.2025 09:38

2022-2025 Ford Maverick Hybrid Battery Cooling Mod: The Ultimate Performance and Longevity Upgrade

08.12.2025 06:50

F-150 3.5 EcoBoost Spark Plug & Coil Replacement DIY: Complete Step-by-Step Guide

08.12.2025 06:44

Mustang GT 2018-2023 Oil Pump Gear Failure: DIY Inspection Guide

08.12.2025 06:34