How to Permanently Fix 5th Gen 4Runner Front Brake Vibration by Rotor Resurfacing (and When You Shouldn’t)

Front brake vibration (steering wheel shake when braking from highway speeds) is one of the most common complaints among 5th generation Toyota 4Runner owners (2010–present). The typical culprit is uneven rotor thickness variation (runout > 0.002–0.003") or hard pad material deposits on the front rotors. While many owners immediately replace rotors and pads, a proper on-car rotor resurface using a Pro-Cut or similar lathe-style brake lathe very often eliminates the pulsation permanently and saves hundreds of dollars.

Why 5th Gen 4Runners Are Especially Prone to Front Brake Judder

The 5th gen platform uses relatively thin 338 mm × 28 mm vented front rotors combined with heavy vehicle weight (4700–4850 lbs) and large 20" or optional 17" wheels. When the truck is used for towing, off-road descents, mountain driving, or repeated hard stops, the rotors overheat easily. Hot spots form, pad material transfers unevenly, and thickness variation develops quickly. Even brand-new OEM rotors from Toyota can develop 0.005–0.010" of runout after only 5,000–8,000 miles of aggressive use.

Symptoms That Point to Rotor-Related Vibration (Not Wheel Bearings or Suspension)

Strong steering wheel shake only under moderate to hard braking above 45 mph

Vibration intensity increases with brake pedal pressure

No vibration during light braking or coasting

Pulsation disappears completely when brakes are cold (first few stops of the day)

Rotor surfaces show blue spots, dark patches, or visible pad imprint

If you feel vibration through the seat or floorboard instead of the steering wheel, the problem is almost always rear brakes or driveline.

When Rotor Resurfacing Actually Works (and When It Doesn’t)

Resurfacing is effective only when:

Measured thickness variation (TV) is ≤ 0.015 mm (0.0006") across the rotor

Disc thickness is still above minimum spec (26 mm stamped on rotor edge)

No cracks longer than 1 inch or reaching the outer edge

No severe hard-spot bluing or martensite spotting

If rotors are already below 26.5 mm or have deep grooves (>0.8 mm), replacement is mandatory. Trying to “save” paper-thin rotors will bring the vibration back in weeks.

Required Tools and Materials for a Professional-Level Fix

Pro-Cut PFM 9.2 (or newer) on-car lathe with 5th gen 4Runner adapter kit

Alternative: Hunter OCL or Reluctor on-car lathes also work

Dial indicator with magnetic base (0.0001" resolution)

Micrometer 0–50 mm (0.001 mm resolution)

Torque wrench (feet-pounds and inch-pounds)

Anti-seize, brake cleaner, silicone paste for slider pins

OEM Toyota or Akebono ProACT ceramic pads strongly recommended (avoid cheap organics)

Step-by-Step On-Car Rotor Resurfacing Process That Eliminates 95 % of Repeat Vibrations

Lift vehicle and support on jack stands. Remove wheels.

Remove caliper and bracket. Hang caliper with bungee — never let it dangle by hose.

Clean hub mating surface aggressively with wire wheel until bare shiny metal shows. Even 0.001" of rust causes runout.

Mount compensating adapter plate and dial indicator. Measure and record total indicated runout at rotor outer edge. Stock acceptable limit is 0.05 mm (0.002"). Most vibrating trucks show 0.08–0.18 mm.

Install Pro-Cut lathe with correct 4Runner arbor and cutting bits. Zero the compensation system — this is the critical.

Perform three finishing passes at slowest feed rate (0.002–0.003" per side total material removal). Never exceed 0.004" total cut or you risk warping thin rotors.

Final surface finish should be 30–60 RA (non-directional swirl) — Pro-Cut machines achieve this automatically.

Remeasure runout — target is ≤ 0.0005" (0.013 mm). Anything under 0.001" is considered perfect.

Clean both sides of rotor with brake cleaner and scotch-brite until no metal dust remains.

Apply thin film of high-temp silicone paste to caliper slider pins and pad ears.

Install new pads (bed-in procedure below). Torque caliper bracket bolts to 90 ft-lbs and caliper guide bolts to 26 ft-lbs.

Critical Bed-In Procedure After Resurfacing

Skipping proper bedding will deposit uneven pad material and bring vibration back in 500 miles.

Recommended 10-stop Toyota method:

Find empty road. Accelerate to 60 mph

Brake firmly (60–70 % pressure) down to 10 mph without stopping completely

Accelerate back to 60 mph

Repeat 10 times allowing 30 seconds cooling between stops

Drive 5–10 miles with no braking to cool rotors

Park and let cool completely (2–3 hours) before next hard braking

Alternative: Off-Car Resurfacing (Not Recommended)

Bench lathes almost always leave 0.003–0.008" runout because hub runout is not compensated. Vibration returns in 3,000–8,000 miles in most documented cases on T4R.org and Toyota-4Runner.org forums.

Real-World Results from Hundreds of 5th Gen Owners

Owners who had rotors resurfaced on-car with Pro-Cut or similar report:

0 % vibration recurrence after 30,000–70,000 miles when paired with quality ceramic pads

Smoother quieter braking than with new rotors in many cases (because runout is virtually zero)

Cost $120–$180 at shops with on-car lathe vs $600–$900 for new OEM rotors + pads + labor

Maintenance Tips to Prevent Vibration from Returning

Clean and re-lubricate caliper slider pins every pad change

Use only ceramic pads (Akebono ProACT, Toyota Genuine, Centric Posi-Quiet Ceramic)

Avoid one-stomp panic stops from highway speeds when rotors are cold

Every 15,000 miles check rotor thickness and runout yourself with dial indicator

If you tow or drive mountains, consider aftermarket 355 mm × 32 mm Tundra brake upgrade instead of fighting stock rotors

A properly executed on-car rotor resurface remains the most cost-effective and reliable fix for 5th gen 4Runner front brake vibration when the rotors still have sufficient thickness and no structural damage.

More from Toyota

2024 Toyota Tacoma i-FORCE MAX Battery Drain Fix – Complete Owner’s Guide

08.12.2025 17:35

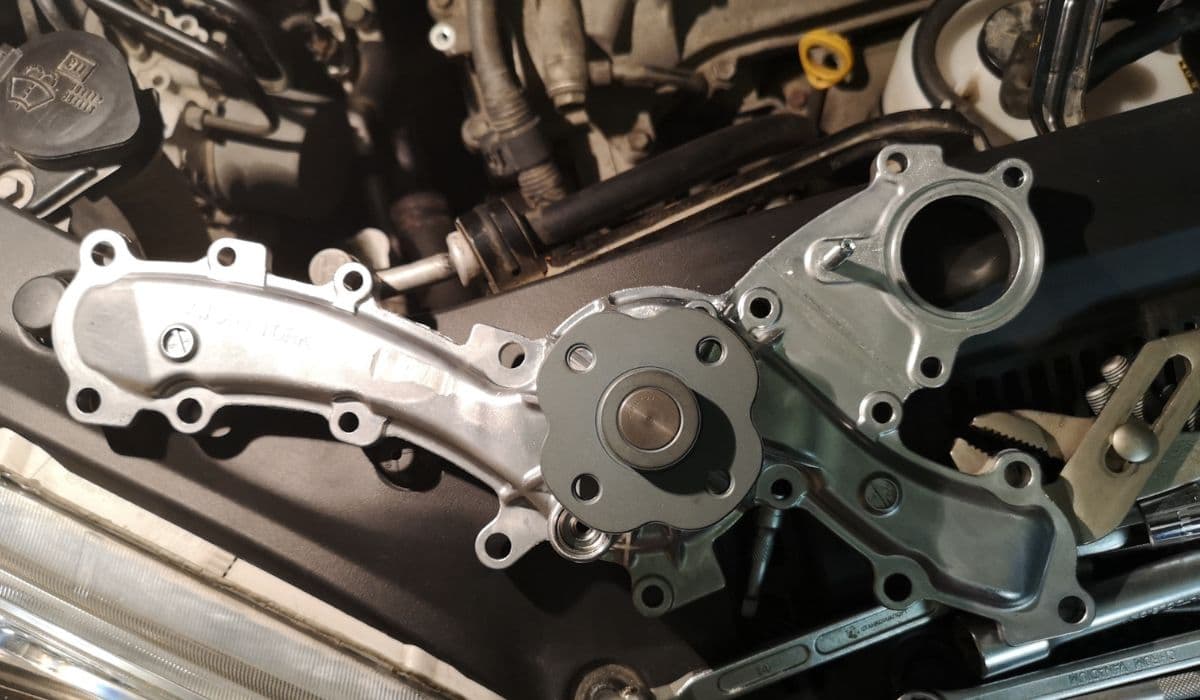

Camry 2GR-FE V6 Water Pump Replacement DIY – Full Step-by-Step Guide

08.12.2025 17:39

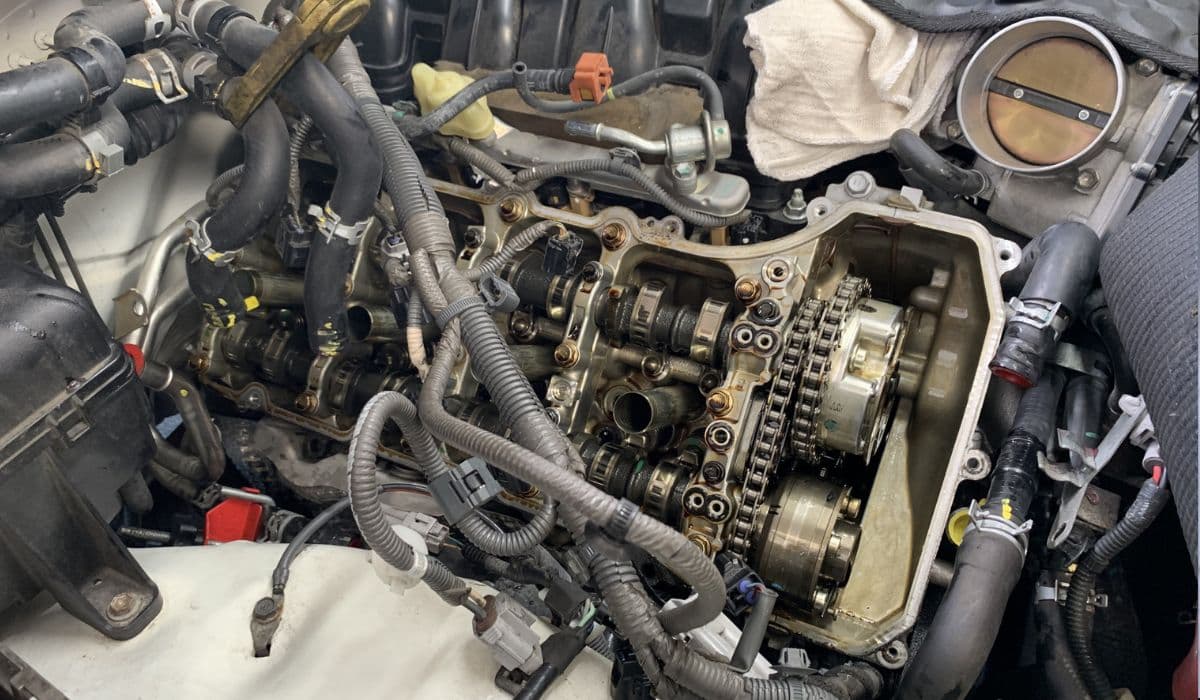

How to Diagnose and Perform 4Runner Transfer Case Actuator Bypass When 4WD Won't Engage

08.12.2025 17:44

Tundra 5.7 Oil Consumption Fix (Piston Rings?)

08.12.2025 17:48

3rd Gen Tacoma Secondary Air Injection Bypass: Complete Guide for 2016-2023 Toyota Tacoma Owners

08.12.2025 17:52