Tundra 5.7 Oil Consumption Fix (Piston Rings?)

The Toyota Tundra's 5.7-liter V8 engine stands out for its robust power delivery and legendary durability, powering heavy loads and long hauls with ease. Yet many owners encounter a frustrating issue: excessive oil consumption. The dipstick shows levels dropping steadily between changes, sometimes requiring a quart every few thousand miles. This phenomenon often sparks the question—is it the piston rings?

Understanding this problem requires looking at how modern engines balance efficiency, emissions, and longevity. The 5.7 V8 employs low-tension piston rings designed to reduce internal friction for better fuel economy and lower emissions. While innovative, these rings prove sensitive to maintenance habits, leading to carbon buildup that impairs their function.

Recognizing the Symptoms of Excessive Oil Use

Spotting oil consumption early prevents bigger headaches down the road. Key indicators include:

Frequent need to add oil between regular services, often 1 quart every 1,000–3,000 miles in affected cases

Blue or grayish smoke from the exhaust, especially during acceleration or after idling

Fouled spark plugs coated in oily residue

No visible external leaks under the vehicle despite dropping oil levels

Possible slight drop in performance or increased fuel use over time

These signs point to oil entering the combustion chamber rather than leaking externally. Unlike a dripping valve cover gasket, internal burning leaves little trace outside the engine.

Primary Causes Behind Oil Burning in the 5.7 V8

Multiple factors contribute, but piston ring issues top the list for many high-mileage examples.

Low-tension oil control rings scrape excess oil from cylinder walls. When carbon deposits (from incomplete combustion or extended intervals) clog the ring grooves or stick the rings, they lose sealing ability. Oil sneaks past into the combustion chamber and burns.

Other contributors include:

Clogged or malfunctioning PCV valve, pulling excess oil vapor into intake

Worn valve stem seals allowing oil down guides

Cylinder wall scoring or excessive wear in rare severe cases

Maintenance lapses accelerating ring coking, such as infrequent oil changes or using lower-quality lubricants

The engine's design prioritizes efficiency, making it more prone to this when neglected compared to older, higher-tension ring setups.

Diagnostic Steps to Pinpoint the Root Cause

Before diving into repairs, confirm the source systematically.

Track consumption precisely over several thousand miles with consistent oil type and driving conditions

Perform a compression test across all cylinders to check ring sealing (low or uneven readings suggest rings)

Conduct a leak-down test for more precise insight into whether rings, valves, or gaskets cause issues

Inspect the PCV system—replace the valve and check hoses for cracks or blockages

Use a borescope to view cylinder walls and piston tops for visible carbon or scoring

These tests separate simple fixes from deeper engine work. A healthy PCV refresh sometimes reduces consumption noticeably.

Effective Solutions: From Simple to Comprehensive

Start conservatively before considering major disassembly.

Non-Invasive Approaches

Switch to a premium full-synthetic oil meeting or exceeding specifications; some owners report reduced burning with slightly thicker viscosities where permitted

Install a fresh PCV valve and inspect related hoses—often the quickest win

Run high-RPM highway drives periodically to help free lightly stuck rings through heat and pressure cycles

Consider specialized engine flush or decarbonization additives designed to clean ring grooves (results vary by severity)

Addressing Stuck or Coked Rings

If carbon buildup is the culprit, cleaning proves more effective than additives alone in moderate cases. Professional chemical cleaning or targeted treatments dissolve deposits, restoring ring movement. This avoids full teardown for many trucks still in reasonable shape.

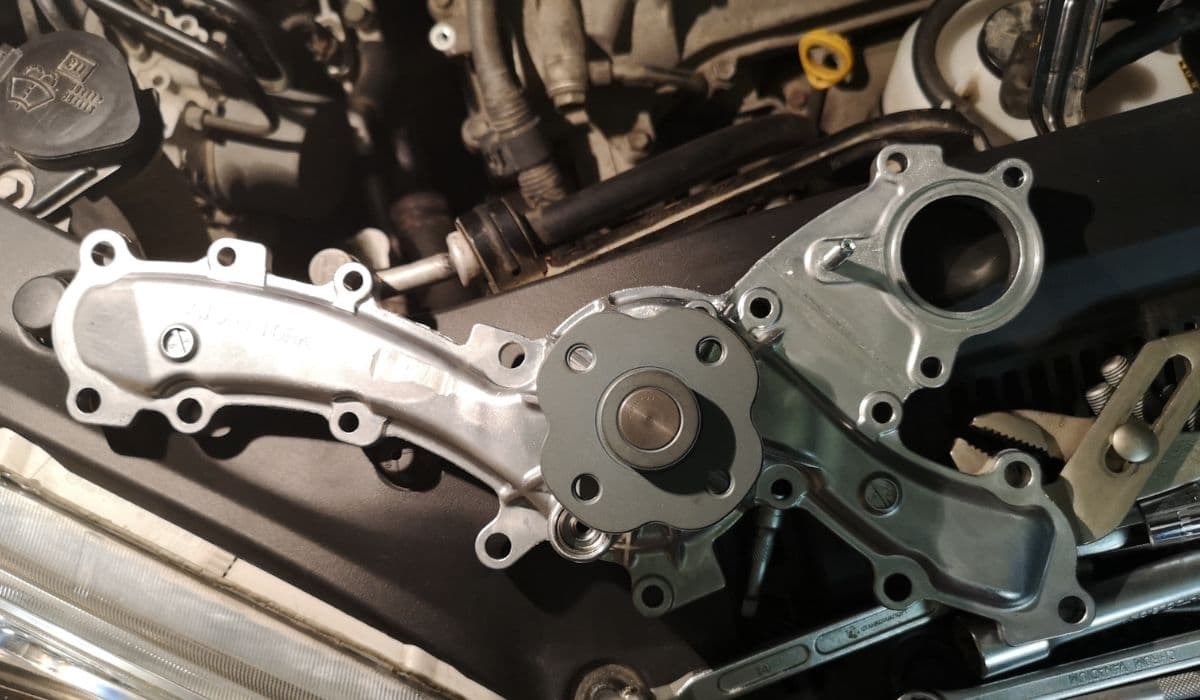

Piston Ring Replacement: The Definitive Fix

When consumption exceeds manageable levels or diagnostics confirm worn/stuck rings, replacing piston rings becomes necessary. This involves:

Engine removal or in-frame access (depending on shop capabilities)

Disassembly of the bottom end to extract pistons

Careful cleaning or honing of cylinder walls

Installation of new piston rings with proper end-gap orientation and stagger

Reassembly with fresh gaskets and torque specs

New rings restore proper oil control, often eliminating the issue entirely. Many choose upgraded or redesigned rings for better long-term performance against coking.

This repair demands expertise and proper tools—amateur attempts risk further damage. A reputable shop familiar with the 3UR-FE engine ensures best results.

Preventive Strategies for Long-Term Reliability

Avoiding recurrence centers on proactive care.

Adhere to shorter oil change intervals under severe conditions (towing, dusty environments, short trips)

Use high-quality synthetic oil with strong detergency to combat deposits

Monitor PCV function regularly and replace proactively

Check oil levels frequently, especially on longer trips

Address any early signs promptly rather than letting low oil exacerbate wear

Consistent attention keeps the powerful 5.7 V8 running smoothly for hundreds of thousands of miles.

More from Toyota

Highlander Hybrid Battery Cooling Fan Cleaning: Complete Step-by-Step Guide

08.12.2025 12:56

How to Diagnose and Perform 4Runner Transfer Case Actuator Bypass When 4WD Won't Engage

08.12.2025 10:44

Camry 2GR-FE V6 Water Pump Replacement DIY – Full Step-by-Step Guide

08.12.2025 10:39

2024 Toyota Tacoma i-FORCE MAX Battery Drain Fix – Complete Owner’s Guide

08.12.2025 10:35

RAV4 Hybrid Inverter Coolant Bleed Procedure: Complete Step-by-Step Guide

08.12.2025 10:31