Tesla heat pump: Vastly improved in cold climates

Tesla's introduction of an advanced heat pump system marked a significant leap forward for electric vehicle performance in winter conditions. Unlike traditional resistive heaters that simply convert electricity into heat with limited efficiency, this innovative thermal management solution dramatically reduces energy waste when temperatures drop. Owners in northern regions now experience noticeably better range preservation, faster cabin warm-up in many scenarios, and overall more comfortable driving without the severe penalties once associated with cold-weather EV operation.

How the Tesla Heat Pump System Actually Works

At the core of Tesla's cold-weather superiority lies a sophisticated heat pump that operates like a highly intelligent air conditioner running in reverse. Instead of generating heat directly, it moves existing thermal energy from one place to another — a process far more efficient than creating heat from scratch.

The system cleverly captures waste heat from:

The battery pack

Drive motors and power electronics

Even the onboard computer systems

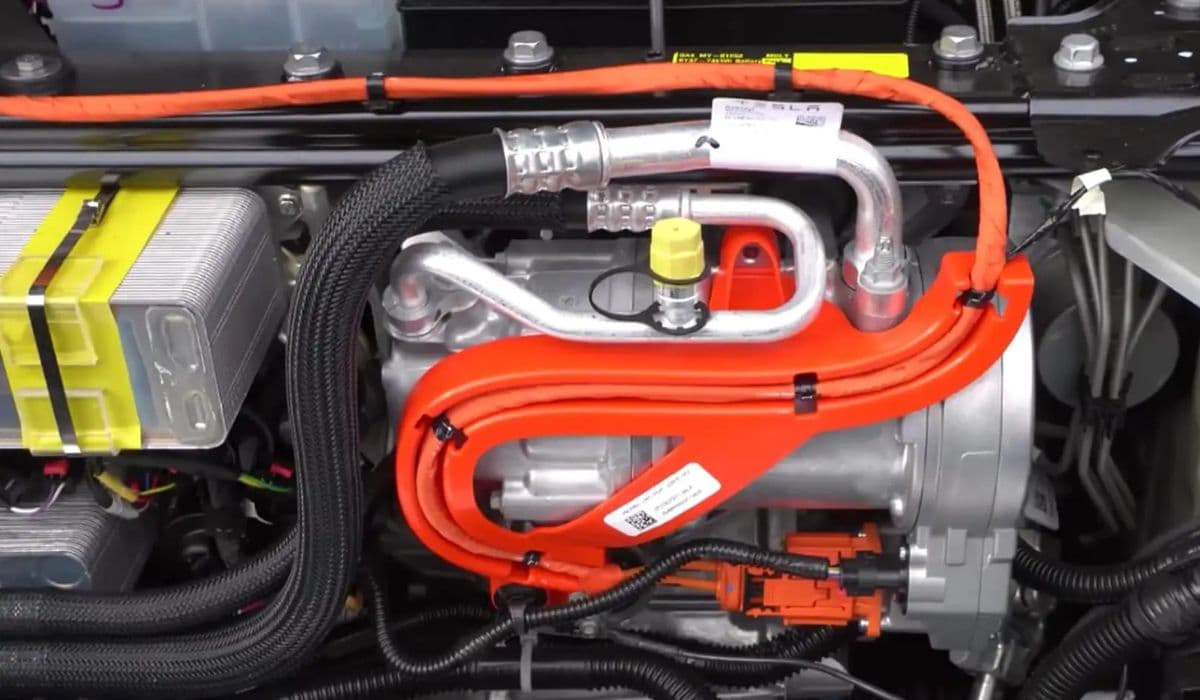

This captured energy gets redirected to warm the cabin or precondition the battery. The real engineering brilliance comes from the Octovalve — a compact, multi-port valve that acts as the system's central nervous system. This device can create numerous different flow paths for coolant and refrigerant, allowing the vehicle to optimize heat distribution in real time based on driving conditions, ambient temperature, and component needs.

In moderate cold (above approximately 14°F / -10°C), the heat pump pulls warmth primarily from outside air and vehicle components with very high efficiency. When temperatures plunge further, the system intelligently supplements with direct heating methods while still maintaining superior overall performance compared to older resistive approaches.

Real Efficiency Gains: What Owners Actually Experience

Independent tests and thousands of owner reports consistently show substantial improvements over vehicles using traditional resistive heating. Here are the key advantages observed in real-world winter driving:

Cabin heating consumption drops dramatically — tests have shown the system using as little as 700-800 watts to maintain comfortable temperatures compared to 2000-3000+ watts in older models

Range preservation improves by 15-20% in typical cold conditions compared to non-heat pump EVs

Energy needed for heating is often 2-3 times lower than resistive systems under the same conditions

Overall winter efficiency frequently reaches levels that surprise even skeptical owners — some report consumption only 8-10% higher than mild weather driving when heating is active

In side-by-side comparisons, vehicles with the heat pump consistently achieve better Wh/mi figures in freezing conditions. The difference becomes even more pronounced on longer trips where cumulative energy savings add up significantly.

Performance in Extreme Cold: Pushing the Boundaries

One of the most impressive aspects of Tesla's design is how well it handles truly severe winter conditions — the kind found in parts of Canada, Norway, and Alaska.

Even at temperatures approaching -20°F (-29°C) and below, the system continues to deliver usable heat while prioritizing battery performance. While efficiency naturally decreases in extreme cold (as with any heat pump), Tesla's approach remains superior to conventional systems. The Octovalve enables smart fallback strategies that keep the cabin comfortable and maintain reasonable range — often outperforming competitors by a noticeable margin in standardized winter range tests.

Owners frequently report:

Reliable cabin defrosting and demisting even in sub-zero temperatures

Much less dramatic "range anxiety" compared to pre-heat pump generations

Consistent performance during multi-day cold snaps without unexpected failures

These results stem from years of iterative development and real-world validation in some of the planet's harshest winter environments.

Additional Cold-Weather Advantages Beyond the Numbers

The benefits extend far beyond raw efficiency metrics. The integrated thermal management creates a more cohesive driving experience in winter:

Preconditioning becomes more energy-efficient, preserving more range when you start your journey

Battery temperature management stays optimized longer, helping maintain strong acceleration and regenerative braking

Component longevity potentially improves through smarter heat distribution

Overall comfort feels more consistent — no sudden blasts of scorching air followed by cooling off

Many drivers in cold climates describe the change as transformative, turning winter EV ownership from a compromise into a genuine strength.

Tesla's heat pump system represents a thoughtful evolution in electric vehicle design, specifically addressing one of the most persistent challenges in cold-climate regions. By moving heat rather than creating it, and orchestrating that movement through the ingenious Octovalve, the company has delivered a solution that keeps drivers warmer, farther, and more confident when temperatures plummet.

More from Tesla

Tesla battery degradation after 100K miles: Real owner data

17.12.2025 15:27

Overall Tesla ownership cost 2025: Cheaper than gas after 3 years?

17.12.2025 12:13

Tesla Cybertruck vs Ford F-150 Lightning: Towing and charging showdown

17.12.2025 05:57

2025 refreshed Tesla Model X: Worth upgrading from old raven?

17.12.2025 04:14

Tesla heat pump problems in winter: 2025 still an issue?

17.12.2025 01:02