Tesla vs rivals reliability: Closing gap on Toyota/Lexus

The automotive world has long revered Toyota and Lexus for their unmatched reliability, setting a benchmark that few competitors could touch. These brands have built their reputations on vehicles that endure high mileage with minimal issues, thanks to refined engineering and conservative innovation strategies. However, a new contender is rapidly emerging in the reliability arena: Tesla. Once criticized for build quality inconsistencies and early production challenges, the electric vehicle pioneer is making significant strides, narrowing the gap with traditional leaders like Toyota and Lexus.

The Traditional Leaders: Toyota and Lexus Dominance

Toyota and Lexus continue to dominate reliability surveys, earning top positions through consistent performance across their lineups. Their approach emphasizes incremental improvements rather than radical overhauls, ensuring that proven components carry over to new models.

Focus on durable powertrains that resist common failures

Rigorous quality control in manufacturing processes

Extensive real-world testing before widespread adoption of new features

Strong track records in body hardware, paint, and interior trim longevity

This methodical strategy results in vehicles that age gracefully, with fewer reported problems in areas like transmissions, engines, and electronics compared to many rivals.

Tesla's Remarkable Turnaround

Tesla's journey in reliability has been transformative. Early models faced scrutiny over issues stemming from rapid scaling and innovative designs. Yet, recent data highlights dramatic improvements, particularly in mainstream offerings.

Model 3 and Model Y now rank among the most dependable electric vehicles in their segments

Enhanced build quality addressing past concerns like panel alignment and suspension components

Over-the-air software updates resolving infotainment and minor electronic glitches proactively

Maturing production techniques leading to fewer assembly-related problems

These advancements have propelled Tesla into higher rankings, demonstrating that the brand is learning quickly from its experiences and applying fixes across its fleet.

Key Factors Driving the Closing Gap

Several elements explain why Tesla is catching up to Toyota and Lexus.

Manufacturing Maturity: High-volume production of core models has allowed Tesla to refine processes, reducing variability that plagued earlier years.

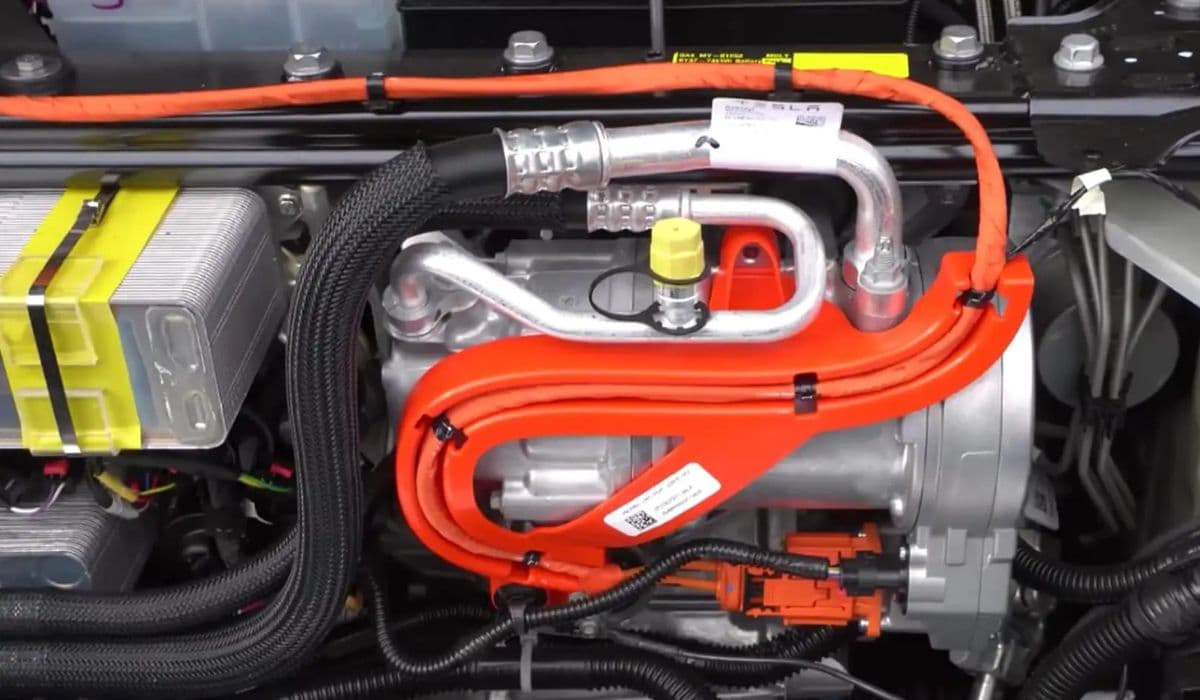

Electric Powertrain Advantages: Fewer moving parts in EVs mean inherent reliability in drivetrains, with batteries and motors proving robust over time.

Data-Driven Improvements: Tesla's connected ecosystem enables real-time monitoring and swift corrections via remote updates.

Owner Feedback Integration: Rapid iteration based on vast telemetry data helps address issues before they become widespread.

In contrast, while Toyota and Lexus excel in hybrid systems, plug-in variants sometimes introduce complexities that affect scores.

Comparing Problem Areas

Reliability surveys reveal shifting patterns in common issues.

Traditional brands like Toyota often lead in mechanical durability but can face challenges with advanced infotainment integrations.

Tesla has overcome early hurdles in body hardware and noise isolation, now competing closely in overall owner satisfaction for daily drivability.

EVs from Tesla show strength in powertrain longevity, while some rivals struggle with battery management or charging systems.

Notably, hybrids remain highly dependable, but pure EVs are stabilizing as technology matures.

What This Means for Buyers

As Tesla closes the reliability gap, consumers gain more options in the electric space without sacrificing peace of mind. Toyota and Lexus retain their edge in long-term used vehicle dependability, ideal for those prioritizing decades of trouble-free ownership. However, for new vehicles, Tesla's progress makes it a compelling alternative, especially for tech-savvy drivers valuing performance and innovation alongside growing reliability.

The competition is intensifying, pushing all manufacturers toward better quality. This evolving landscape benefits everyone, offering vehicles that combine efficiency, excitement, and endurance in ways previously unimaginable.

More from Tesla

Tesla battery degradation after 100K miles: Real owner data

17.12.2025 15:27

Overall Tesla ownership cost 2025: Cheaper than gas after 3 years?

17.12.2025 12:13

Tesla Cybertruck vs Ford F-150 Lightning: Towing and charging showdown

17.12.2025 05:57

2025 refreshed Tesla Model X: Worth upgrading from old raven?

17.12.2025 04:14

Tesla heat pump problems in winter: 2025 still an issue?

17.12.2025 01:02