How to fix ABS module BMW faults

The Anti-lock Braking System (ABS) in BMW vehicles is a critical safety feature that prevents wheel lockup during emergency stops, maintaining steering control on slippery surfaces. Integrated with Dynamic Stability Control (DSC) in many models, the ABS module—often combined with the pump and hydraulic unit—processes signals from wheel speed sensors to modulate brake pressure. When this module develops faults, it can trigger warning lights and disable advanced braking aids, compromising vehicle safety. Understanding these issues empowers owners to address them effectively without unnecessary replacements.

Understanding the ABS Module in BMWs

The ABS module serves as the brain of the system, interpreting data from four wheel speed sensors and activating the pump to pulse brakes rapidly when skidding is detected. In BMWs, particularly older series like the E39 5 Series, E46 3 Series, and E90 3 Series, the module is prone to internal failures due to heat exposure, vibration, and solder joint degradation over time. Newer models with integrated DSC add layers of traction and stability management, making module faults more noticeable through multiple dashboard warnings.

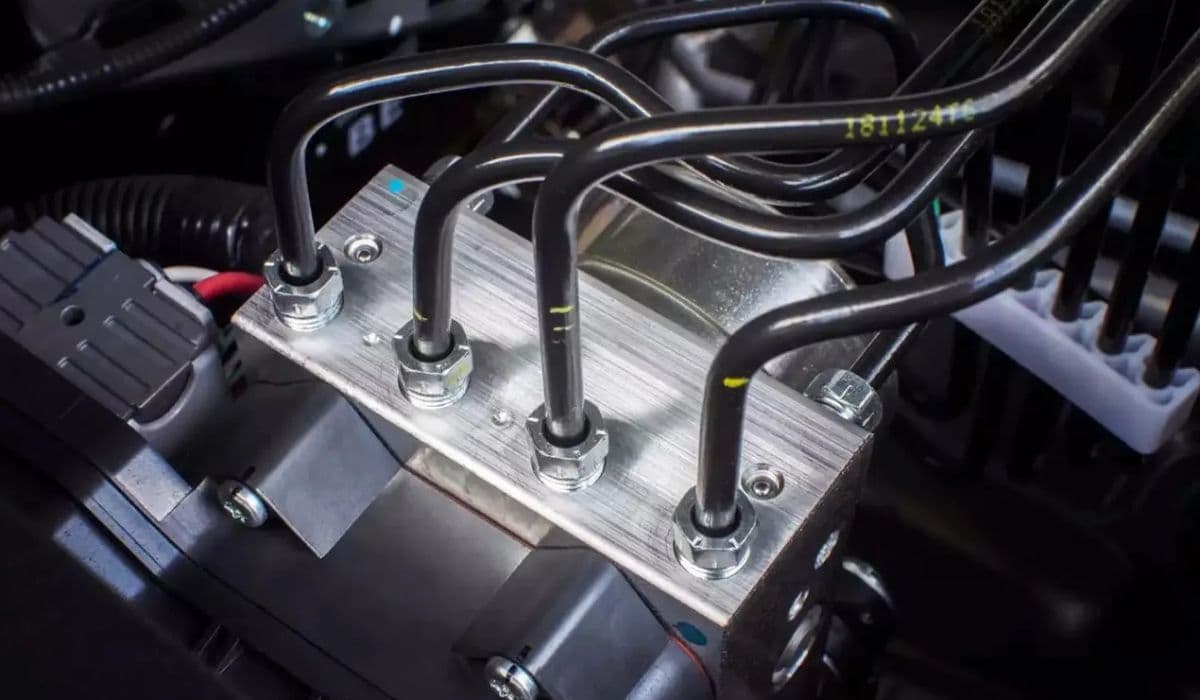

Common configurations include the control unit mounted directly on the hydraulic pump assembly, located in the engine bay. This design, while compact, exposes electronics to harsh conditions, leading to premature wear.

Common Symptoms of ABS Module Faults

Recognizing early signs allows for timely intervention before complete system failure.

Illuminated ABS, DSC, and brake warning lights on the dashboard, often appearing together (known as the "trifecta").

Intermittent faults that start after the engine warms up, due to thermal expansion affecting solder connections.

Erroneous wheel speed sensor codes, typically pointing to one rear sensor despite replacements not resolving the issue.

Loss of speedometer function or erratic readings, as the module relays speed data.

Reduced braking performance in wet conditions, with potential pump motor noise or unresponsive stability control.

Stored fault codes like internal pressure sensor errors or pump motor failures when scanned.

These symptoms often progress from occasional to permanent, highlighting the need for prompt diagnostics.

Causes Behind BMW ABS Module Problems

Several factors contribute to module degradation in BMWs.

Cracked or cold solder joints on the circuit board from repeated heating and cooling cycles.

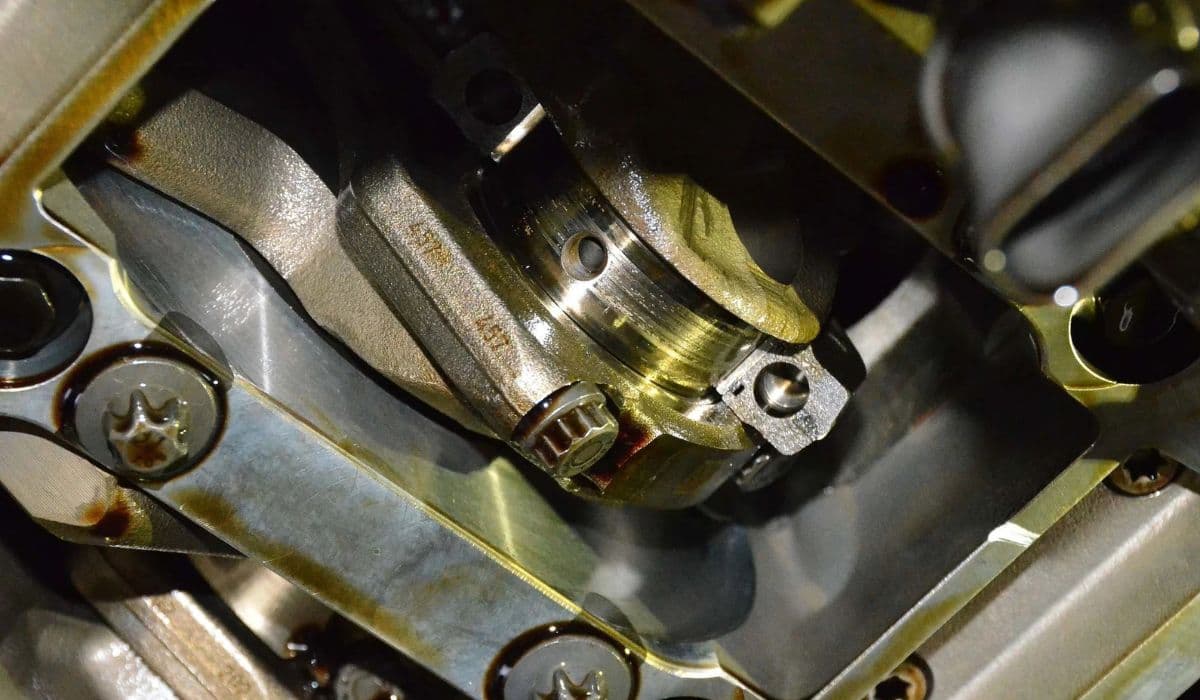

Faulty pre-charge or return pump motor, where brushes stick or electrical contacts fail.

Internal electronic component breakdown, such as relays or drivers for valves and sensors.

Moisture ingress or corrosion in connectors, exacerbated by road salt and underhood humidity.

High mileage and age-related wear, common in vehicles from the early 2000s onward.

In models like the E39 and E90, heat from nearby exhaust components accelerates these issues, making proactive maintenance essential.

Diagnosing ABS Module Faults

Accurate diagnosis prevents misattributing problems to sensors or wiring.

Use a BMW-compatible scanner (such as INPA, ISTA, or advanced OBD tools) to retrieve specific codes from the ABS/DSC module.

Check live data for wheel speed signals; inconsistencies often trace back to the module rather than sensors.

Inspect wiring harnesses and connectors for damage, corrosion, or loose pins.

Test battery voltage and grounds, as low power can mimic module faults.

Perform a self-test by monitoring if lights activate only after driving or heating.

Professional scans reveal codes pointing to internal module errors, distinguishing them from peripheral issues.

Step-by-Step Troubleshooting Before Repair

Start with simpler checks to rule out external causes.

Clean and inspect all wheel speed sensors and their tone rings for debris or damage.

Verify brake fluid level and condition; old fluid can cause hydraulic inconsistencies.

Examine fuses and relays related to the ABS system.

Disconnect and reconnect the module harness to reseat connections.

Drive the vehicle to activate the system, noting if faults clear temporarily (e.g., after tapping the pump).

If codes persist and point internally, the module likely requires attention.

Repair Options for Faulty ABS Modules

Many BMW owners opt for repair over full replacement due to reliability and retention of original coding.

Professional rebuilding services disassemble the unit, reflow solder joints, replace prone components like relays and brushes, and test thoroughly.

Rebuilders often upgrade parts for enhanced durability, addressing original design weaknesses.

DIY enthusiasts with soldering experience can attempt reflowing joints on accessible boards, though encapsulated units in newer models complicate this.

After repair, the module typically reinstalls plug-and-play, with no recoding needed in most cases.

Rebuilding preserves vehicle-specific adaptations and often includes extended warranties.

Professional vs. DIY Fixes

While DIY reflows succeed on older exposed boards, professional services ensure comprehensive testing on specialized benches simulating real conditions.

Pros handle gel-filled or complex units safely, preventing further damage.

They identify subtle faults like trace cracks under magnification.

For hydraulic-integrated assemblies, experts secure components during shipping to avoid fluid leaks.

Entrusting to specialists minimizes risks and maximizes longevity.

Preventing Future ABS Module Issues

Regular care extends system life significantly.

Flush brake fluid periodically to prevent moisture buildup and corrosion.

Avoid deep water crossings that could splash the underhood area.

Park in covered spaces to reduce thermal stress.

Exercise the system occasionally through controlled hard stops on safe surfaces.

Monitor for early intermittent warnings and address promptly.

These habits keep the ABS module functioning reliably for years.

Reinstallation and Testing After Fix

Once repaired:

Secure the module back in its bracket, reconnect brake lines carefully if removed, and torque properly.

Bleed the brakes thoroughly to remove air, using a scan tool for ABS-specific cycles if available.

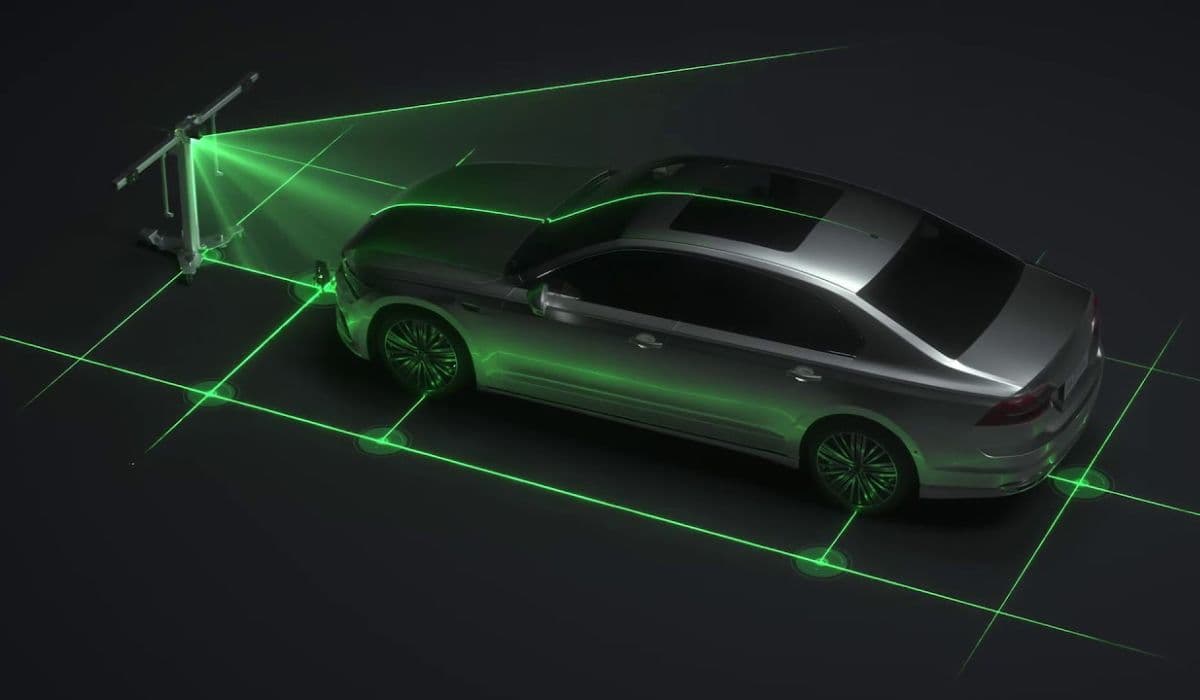

Clear all fault codes and road test, verifying no lights return and full functionality restores.

Confirm speedometer and stability features operate normally.

A successful fix returns the BMW to peak braking safety.

More from BMW

BMW: How to replace coolant hoses and expansion tank

20.12.2025 11:51

How to fix rod knock in tuned BMW S55 engines

20.12.2025 11:41

How to replace high-pressure fuel pump BMW(HPFP)

20.12.2025 11:38

How to fix ADAS camera BMW calibration after windshield

20.12.2025 11:02

BMW: How to replace door handle carrier (interior melt)

20.12.2025 09:55