How to fix rod knock in tuned BMW S55 engines

The BMW S55 engine, a twin-turbo inline-six powerhouse found in high-performance models like the M3 and M4, delivers exhilarating performance, especially when tuned for higher boost and power output. However, tuned S55 engines can develop rod knock—a deep, metallic knocking sound from the lower end—due to excessive stress on the rod bearings. This issue arises more frequently in modified setups where increased torque and horsepower amplify loads on the bottom end. Addressing rod knock promptly is crucial to prevent catastrophic engine failure, as ignored symptoms can lead to spun bearings or worse.

Understanding Rod Knock in the S55

Rod knock occurs when the rod bearings, which separate the connecting rods from the crankshaft, wear out excessively, creating unwanted clearance. In a tuned S55, this is exacerbated by higher cylinder pressures, elevated oil temperatures, and aggressive driving styles that push the engine beyond stock limits.

Common triggers in tuned applications include:

Aggressive tuning maps that spike torque early in the RPM range

Inadequate oil film strength under extreme loads

Prolonged high-RPM operation on track days

Suboptimal oil flow during hard cornering or launches

Unlike the more notorious rod bearing issues in predecessors like the S65 V8, the S55's forged crankshaft and improved design make it more resilient stock. Yet, tuning shifts the balance, making proactive monitoring essential for enthusiasts chasing big power numbers.

Diagnosing Rod Knock Accurately

Misdiagnosing rod knock is common, as other noises—like injector tick, exhaust camshaft issues, or even accessory drive problems—can mimic it. A true rod knock typically presents as a deep, rhythmic thud that worsens under load and follows engine RPM.

Key diagnostic steps:

Listen carefully at idle and under acceleration; rod knock often intensifies around 2000-3000 RPM and quiets when revs rise further in early stages

Perform a cylinder disable test: Disconnect ignition coils one by one while running—if the knock diminishes significantly on a specific cylinder, that rod is likely the culprit

Check oil for metal particles: Drain and inspect for glitter or shavings, a telltale sign of bearing material shedding

Use a mechanic's stethoscope on the block to pinpoint the lower end origin

Send an oil sample for analysis to detect elevated metals like copper or lead from bearing wear

Differentiate from common S55 quirks, such as valvetrain tick or turbo-related noises, by noting that genuine rod knock rarely vanishes completely and persists even when warm.

Causes Specific to Tuned S55 Engines

Tuning amplifies the S55's inherent strengths but also exposes vulnerabilities in the bottom end lubrication system. Stock S55 engines rarely suffer premature rod bearing failure with proper care, but modifications change the equation.

Primary factors in tuned setups:

Thinner oil film from heat buildup in high-boost scenarios

Oil starvation during sustained high lateral G-forces on track

Increased crankshaft flex under elevated torque

Delayed warm-up habits combined with immediate hard throttle input

Many tuned owners report issues emerging after stage 2 or higher tunes, particularly if oil viscosity isn't upgraded to match the power gains.

Repair Options for Rod Knock

If diagnosis confirms rod knock, stop driving immediately to minimize damage. Repair complexity depends on severity—early detection might allow bearing replacement, while advanced cases could require crankshaft work.

Standard repair process:

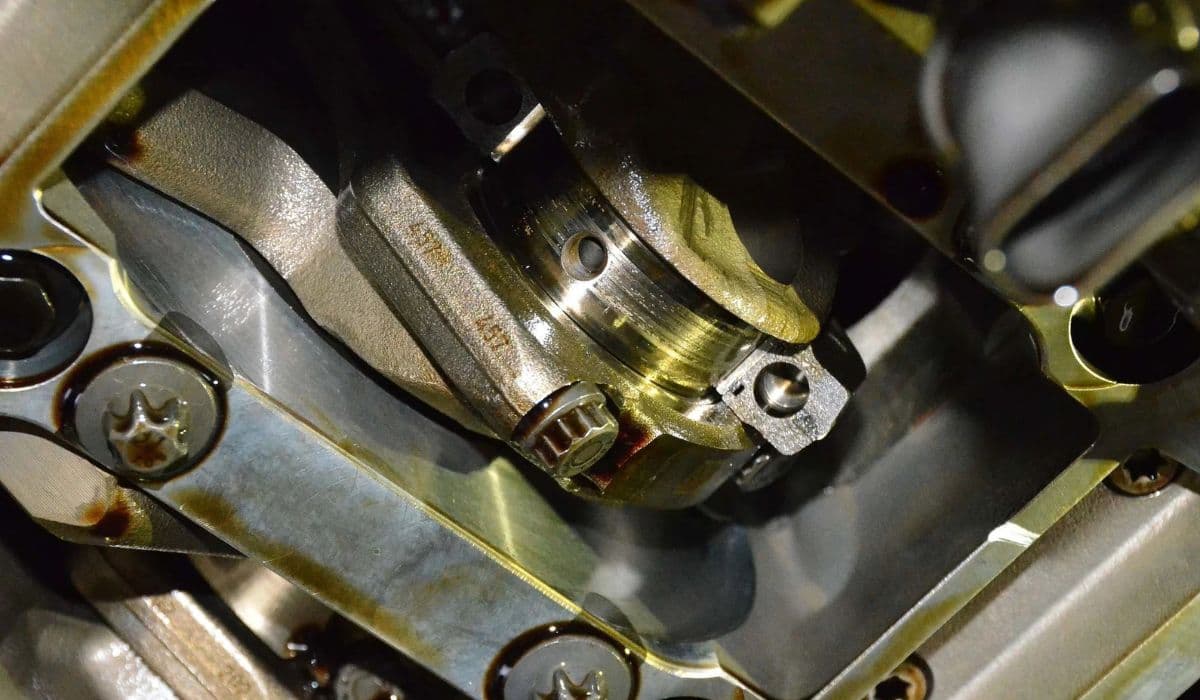

Drop the oil pan for access (subframe removal often needed on these chassis)

Inspect all rod bearings for scoring, spinning, or excessive clearance

Measure crankshaft journals for damage; polish if minor, replace if scored deeply

Install upgraded bearings designed for higher loads, often with specialized coatings for better protection

Torque everything to spec with new rod bolts for security

In severe cases, a full bottom-end rebuild or engine swap becomes necessary. Skilled technicians familiar with BMW M engines are vital, as precise clearances ensure longevity post-repair.

Preventive Measures for Tuned S55 Owners

Prevention beats repair every time, especially in a performance-oriented engine like the S55. Tuned examples thrive with thoughtful maintenance upgrades.

Essential strategies:

Switch to higher-viscosity full-synthetic oil suited for extreme conditions

Shorten change intervals significantly under hard use

Allow thorough warm-up before boosting heavily

Monitor oil pressure and temperature via gauges or OBD tools

Consider aftermarket solutions like enhanced baffling for better oil control during aggressive driving

Many enthusiasts perform preemptive bearing replacements during other service work, pairing it with inspections to catch wear early. Consistent oil analysis provides peace of mind, revealing trends before audible symptoms appear.

Tuned S55 engines reward diligent owners with reliable, heart-pounding performance. By understanding rod knock risks and staying vigilant, you can keep the inline-six singing smoothly for miles of thrilling drives.

More from BMW

How to replace high-pressure fuel pump BMW(HPFP)

20.12.2025 11:38

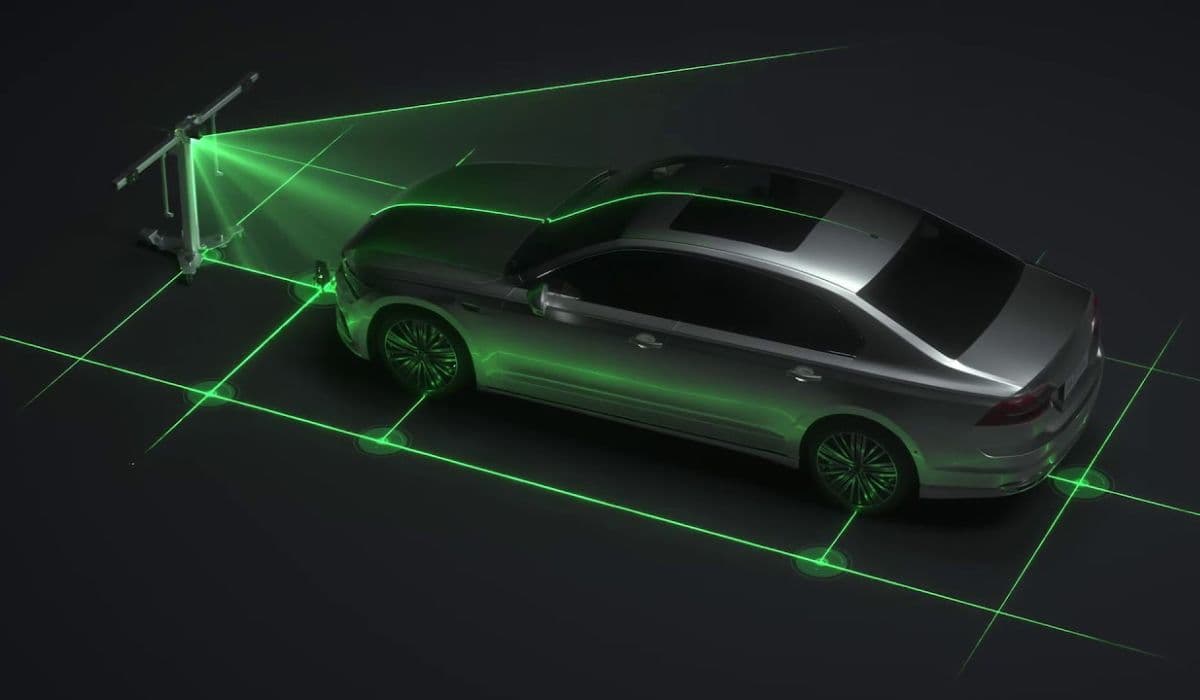

How to fix ADAS camera BMW calibration after windshield

20.12.2025 11:02

BMW: How to replace door handle carrier (interior melt)

20.12.2025 09:55

BMW: How to replace front lower control arms

20.12.2025 09:48

How to fix infotainment curved display glitches BMW

20.12.2025 09:44