How to fix brake booster vacuum issues BMW

Brake booster vacuum problems rank among the most frustrating yet safety-critical issues BMW owners face. That sudden stiff pedal that turns effortless braking into a workout session, or the mysterious loss of power after a few pumps — these symptoms often point to vacuum-related failures in the brake booster system. BMW models, especially those with naturally aspirated engines or diesel variants relying on vacuum pumps, are particularly susceptible due to their design and age-related wear.

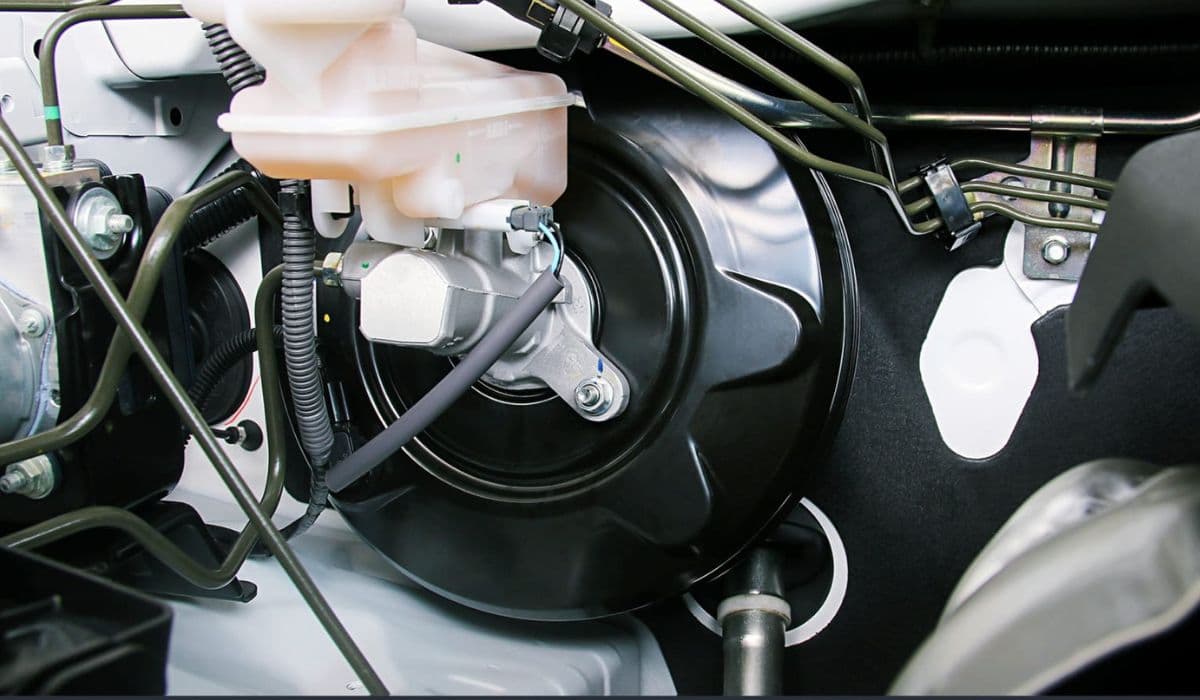

Understanding how the system works helps demystify the problem. The brake booster uses engine vacuum (or vacuum from an auxiliary pump) to multiply your foot pressure, making braking feel light and precise. When vacuum drops, you lose that assistance — and suddenly you're fighting the pedal like it's a heavy-duty truck.

Common Symptoms of Brake Booster Vacuum Problems

Recognizing the signs early can prevent dangerous situations on the road. Here are the most typical indicators BMW drivers report:

Rock-hard brake pedal — especially noticeable after the engine has been running for a while or during extended idling

Pedal requires significantly more force to press, often feeling like you're pushing against a wall

Brakes work normally for the first 1-3 pumps after starting, then become progressively harder

Intermittent loss of power assist, sometimes returning after revving the engine

Engine may run roughly or show high fuel trims (if vacuum leak affects intake)

In rare cases, hissing sound from under the dashboard when pressing the pedal

These symptoms usually develop gradually, making them easy to ignore until braking becomes noticeably compromised.

Primary Causes of Vacuum Issues in BMW Brake Boosters

BMW brake systems are robust, but several weak points commonly fail over time:

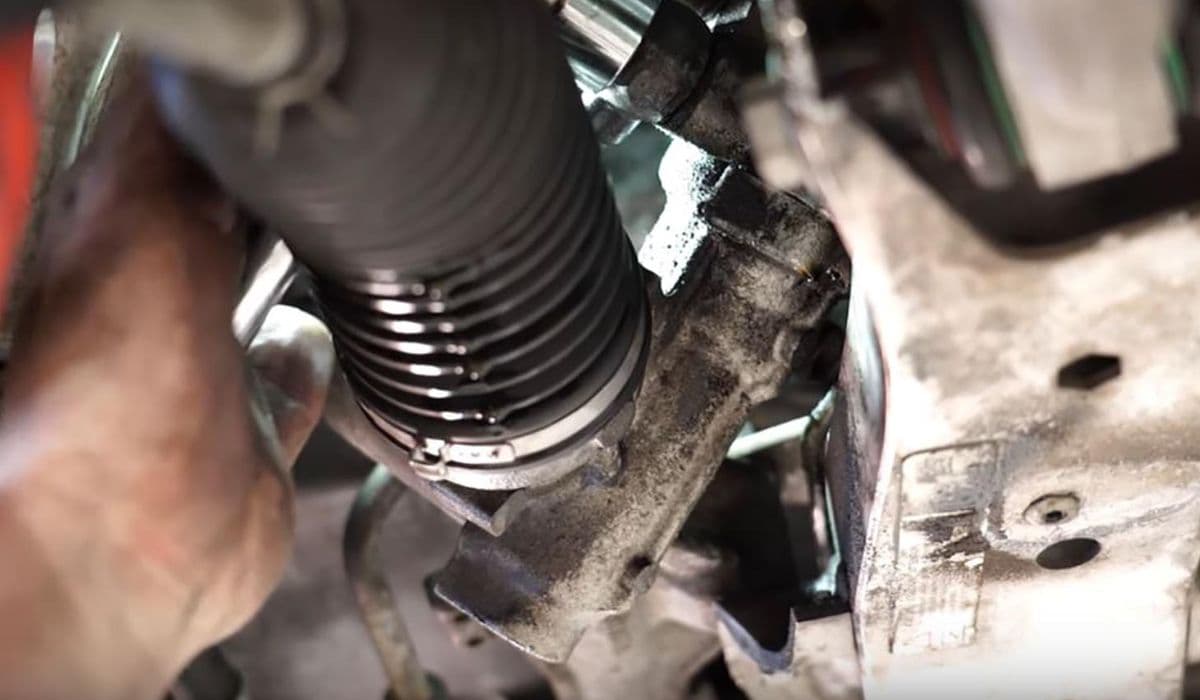

Cracked, brittle, or collapsed vacuum hose — Rubber deteriorates, especially near hot engine components

Faulty one-way check valve — This small but critical part allows vacuum in but prevents backflow; when it fails, vacuum escapes

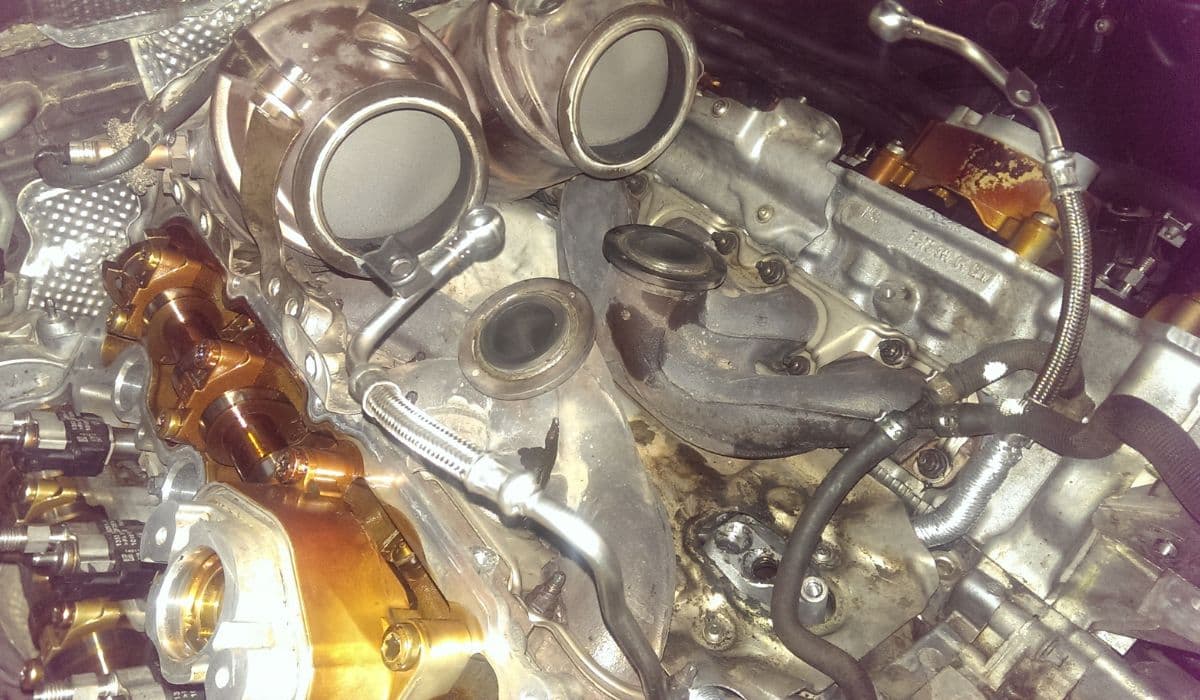

Internal diaphragm rupture in the booster — Often caused by oil contamination from a leaking vacuum pump or line

Leaking vacuum pump (common on diesel and some V8 models) — Oil enters the line and eventually damages the booster

Corroded or loose fittings at the intake manifold or booster connection

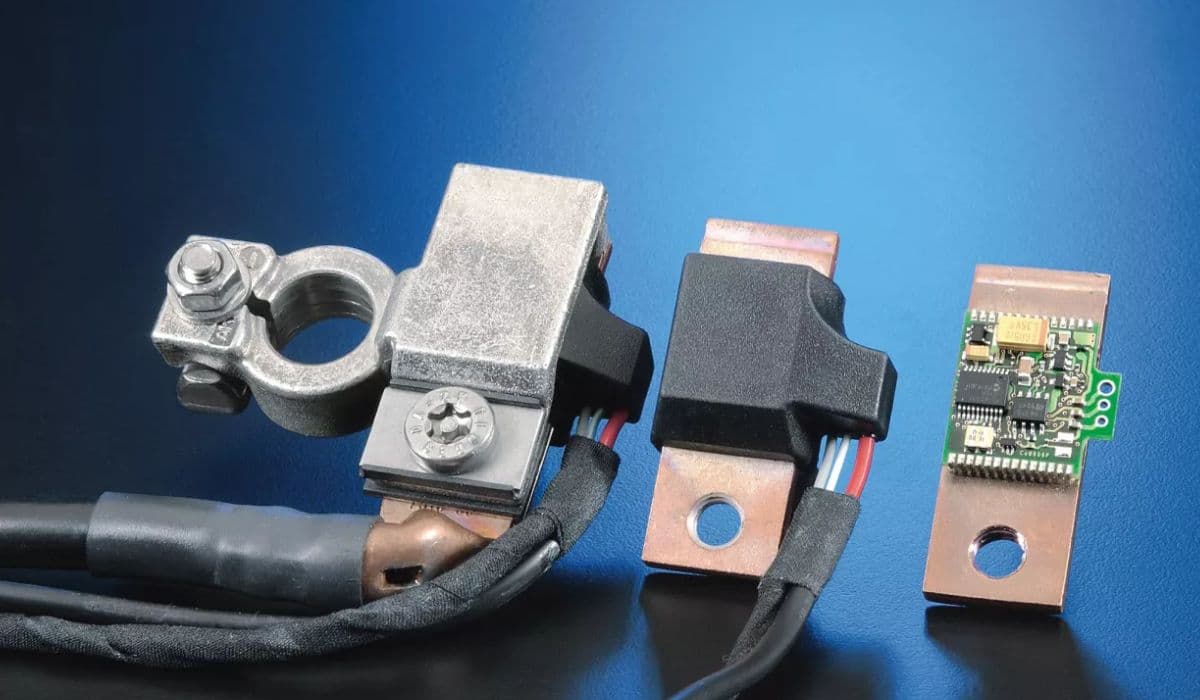

Failed vacuum sensor or electric pump issues on models with auxiliary vacuum systems

The combination of oil contamination and diaphragm damage appears frequently on E60, E90, and similar platforms.

Step-by-Step Diagnosis of Vacuum Problems

Proper diagnosis saves time and money. Follow these tests in order — they require minimal tools and can pinpoint the issue quickly.

Test 1: Basic Pedal Reserve Check

Engine off, pump the brake pedal 20-25 times to deplete stored vacuum

Pedal should become very hard after 4-6 pumps

Start the engine while holding moderate pressure on the pedal

Good system: pedal should sink noticeably (about 1-2 inches) as vacuum builds

No movement or very little: vacuum supply problem

Test 2: Engine Running Hold Test

Start engine and press brake pedal firmly

Hold pressure and turn engine off

Pedal should remain firm for at least 30-60 seconds

If pedal rises slowly: internal booster leak (most likely diaphragm)

Rapid rise: major leak in hose, check valve, or connection

Test 3: Check Valve Functionality

Locate the check valve (usually plastic, inserted into booster)

Remove vacuum hose from intake/check valve side

Blow through the hose toward the booster — air should pass easily

Try blowing the opposite direction — almost no air should pass

If air flows both ways: replace check valve immediately

Test 4: Vacuum Source Verification

Disconnect hose at intake manifold (or vacuum pump outlet)

Attach vacuum gauge (cheap tool, highly recommended)

At idle, expect 18-22 inHg (strong vacuum)

Rev engine slightly — vacuum should remain stable

Below 15 inHg: engine vacuum problem or weak pump

Bonus Detection Trick

On many BMWs, disconnecting/plugging the booster vacuum hose at the intake manifold and monitoring idle quality can reveal if the booster is consuming excessive vacuum (indicating internal leak).

Effective Repair Solutions

Once diagnosed, repairs range from simple to moderately involved:

Replace the vacuum hose and check valve — Often solves 60-70% of cases; use OEM-quality parts for longevity

Install new check valve grommet/seal — Tiny rubber piece that hardens and leaks over time

Clean and inspect all fittings — Remove oil residue if present

Replace the brake booster — Required when diaphragm is damaged; involves removing master cylinder (bleed brakes afterward)

Address vacuum pump issues — On affected models, replace pump and contaminated lines/hoses

Check for oil in booster — If present, replace booster and trace source (usually pump or line failure)

Always bleed the brake system thoroughly after any component replacement to restore proper pedal feel.

Prevention Tips for Long-Term Reliability

BMW brake vacuum systems reward proactive maintenance:

Inspect vacuum hoses every 2 years or during major services

Replace check valve proactively at 100-150k km intervals

Monitor for oil in vacuum lines during oil changes

Use quality parts — cheap aftermarket hoses fail quickly

Address any rough idle or high fuel trims promptly, as they often share vacuum leak causes

A reliable brake booster isn't just about comfort — it's essential for confident, predictable stopping power that BMW drivers expect.

More from BMW

How to fix DSC/ABS wheel speed sensor faults BMW

13.12.2025 13:46

How to replace run-flat tires and reset TPMS BMW

13.12.2025 13:40

How to fix electronic steering rack clunk BMW

13.12.2025 13:35

How to fix crankcase ventilation (PCV) valve heater BMW

13.12.2025 13:13

How to replace IBS battery sensor false errors BMW

13.12.2025 13:06