How to fix electronic steering rack clunk BMW

The unmistakable clunk from your BMW's steering system can turn an otherwise smooth drive into an irritating experience. This noise often appears when hitting small bumps, potholes, or even when rocking the steering wheel with the car stationary. In many BMW models equipped with electronic power steering (EPS), the culprit is rarely a completely failed rack. Instead, it's usually excessive play in a specific internal component that develops over time due to normal wear.

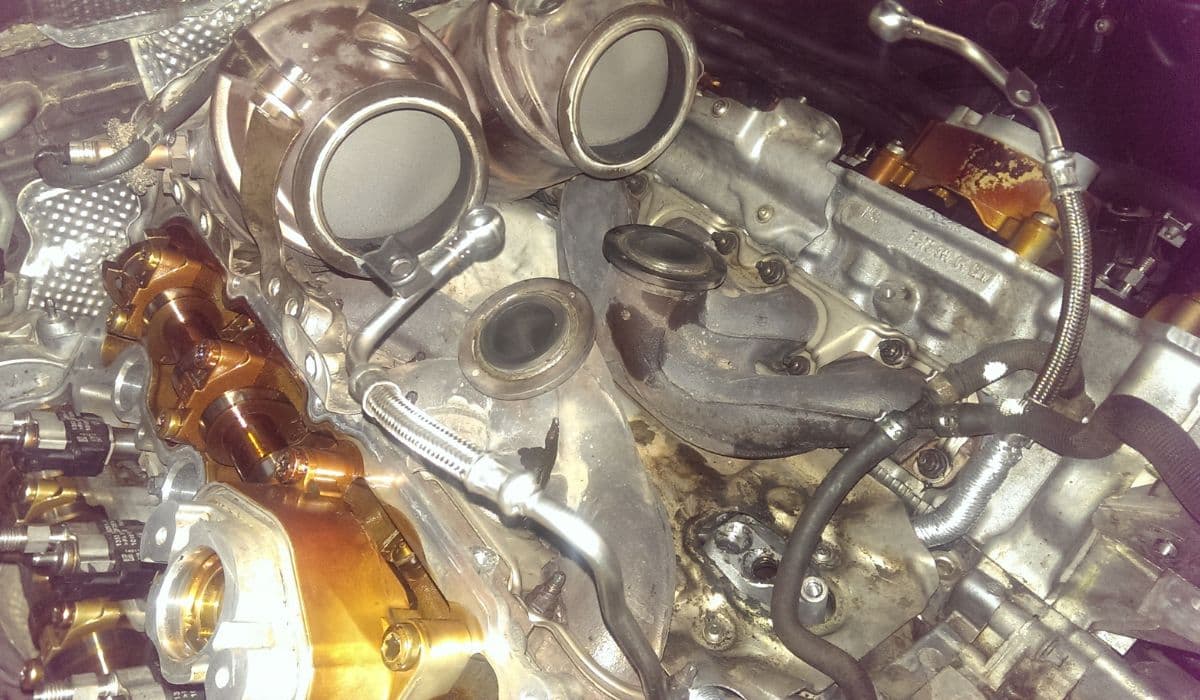

Understanding the root cause empowers owners to address the issue effectively without assuming the worst. Modern BMW EPS racks integrate an electric motor directly onto the rack assembly for precise assistance, but this design introduces unique wear points compared to older hydraulic systems.

Common Causes of Clunking in BMW Electronic Steering Racks

The clunk typically originates from internal clearance that allows unwanted movement between the rack gear and pinion.

Worn Thrust Piece or Pressure Yoke — The most frequent offender in EPS setups. This component (often called the thrust bearing, damper, or pressure piece) presses the rack bar against the pinion gear to eliminate backlash. Over thousands of miles, the original plastic or composite material compresses or wears, creating slack that translates into audible clunks and sometimes a perceptible knock through the wheel.

Internal Bushing Degradation — Related bushings or supports inside the rack housing lose their firmness, allowing micro-movements amplified during road impacts.

Tie Rod or Inner Joint Play — While less common for pure steering clunks, worn inner tie rod ends can mimic rack noise, especially if play exists where they connect to the rack.

Motor Belt or Mounting Issues — In some EPS designs, a toothed belt connects the electric motor to the rack. Loose tension or wear here can produce clicking or skipping sounds during turns.

Other Front-End Contributors — Loose sway bar links, worn bushings, or even intermediate steering shaft U-joints occasionally produce similar symptoms, though they usually clunk more during suspension travel than pure steering input.

Pinpointing the electronic rack as the source involves simple tests that isolate it from suspension or column problems.

Accurate Diagnosis Steps Before Any Repairs

Proper diagnosis prevents unnecessary part replacements and ensures the fix targets the real issue.

Park on a level surface and turn the engine off. Rock the steering wheel left and right quickly — if a distinct clunk or knock echoes from the steering column area, note whether it's felt in the wheel or heard lower in the front end.

Jack up the front of the vehicle so both wheels are off the ground. Grab the driver's side tire at the 3 and 9 o'clock positions and push-pull vigorously. Play or clunk directly from the rack area (often more pronounced on one side) strongly indicates the thrust piece issue.

With the engine running, repeat the stationary wheel rocking test. EPS assistance often masks minor play when powered, so the noise disappearing with the engine on points toward internal rack clearance rather than a binding mechanical fault.

Inspect visible components: check for loose motor mounting bolts on the rack, any obvious play in tie rods, and listen for belt-related clicks during slow turns.

Drive over low-speed bumps or rough patches while paying attention to when the clunk occurs — steering-related noise tends to happen during direction changes or over small imperfections, while suspension clunks are more consistent with vertical movement.

These checks usually confirm the electronic rack thrust component as the primary source in most reported cases.

Step-by-Step Guide to Fixing the Clunk

Many BMW owners successfully eliminate the noise with targeted adjustments or minor part replacements rather than a full rack swap.

Adjustment Method (Non-Invasive First Step)

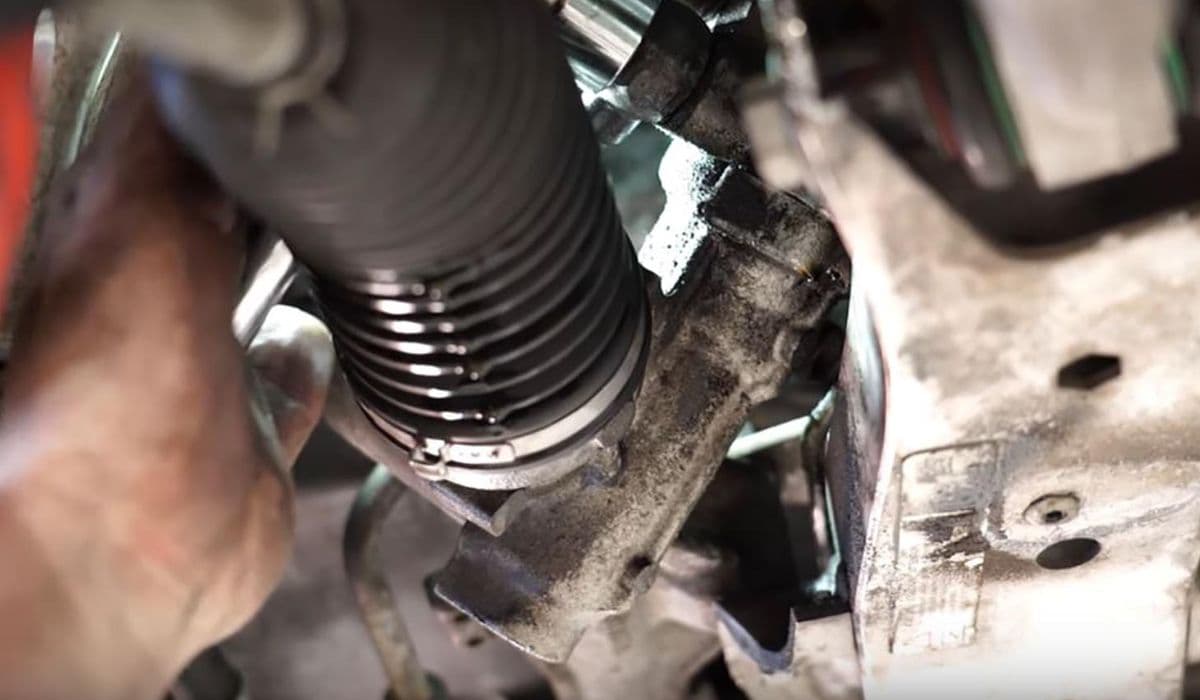

This approach tightens the existing thrust piece to remove excess play without disassembly.

Safely lift the front wheels off the ground to unload the steering system.

Locate the adjustment cap or plug on the steering rack housing (typically on the driver's side, covered by a small plastic cap near the pinion area).

Use an appropriate socket (often around 5/8" or a specific three-prong tool) to access the thrust adjuster underneath.

Turn the adjuster clockwise in very small increments — start with 1/16 to 1/8 turn.

Lower the car, test drive over familiar bumpy roads, and repeat the rocking test.

Fine-tune by repeating the process: tighten slightly if clunk persists, back off if steering feels overly tight or binds during full lock-to-lock turns.

Aim for zero perceptible play without inducing drag — overtightening accelerates future wear or causes uneven steering effort.

Thrust Piece Replacement (More Permanent Solution)

When adjustment alone isn't sufficient or the wear is advanced, install an upgraded repair kit.

Obtain the official BMW thrust piece repair kit, which includes a higher-durability bushing or upgraded pressure yoke designed to resist compression better than the factory original.

With the front elevated, remove the protective cap and use specialized tools (or careful socket work) to extract the old component.

Clean the area thoroughly to remove debris.

Install the new piece, ensuring proper seating.

Adjust tension carefully per the incremental method above, testing repeatedly to achieve smooth, quiet operation without binding.

Many owners report this fix lasting significantly longer, restoring confident steering feel.

Additional Checks During the Process

While addressing the rack:

Inspect and tighten any accessible rack mounting bolts.

Verify electric motor connections and belt condition if applicable.

Lubricate or replace intermediate shaft U-joints if play exists there.

These steps often resolve the annoyance completely, bringing back the precise, connected steering BMWs are renowned for.

Preventing Future Clunk Issues

Proactive care extends the life of your EPS system.

Regularly inspect front-end components during routine maintenance.

Avoid aggressive impacts over deep potholes when possible.

Consider upgraded aftermarket thrust pieces known for superior material durability if the issue recurs.

Keep steering inputs smooth on rough surfaces to minimize stress on internal components.

Mastering this common quirk transforms what feels like a major fault into a straightforward maintenance task. With careful diagnosis and the right approach, your BMW's electronic steering rack can deliver quiet, responsive performance for many more miles ahead.

More from BMW

How to fix crankcase ventilation (PCV) valve heater BMW

13.12.2025 13:13

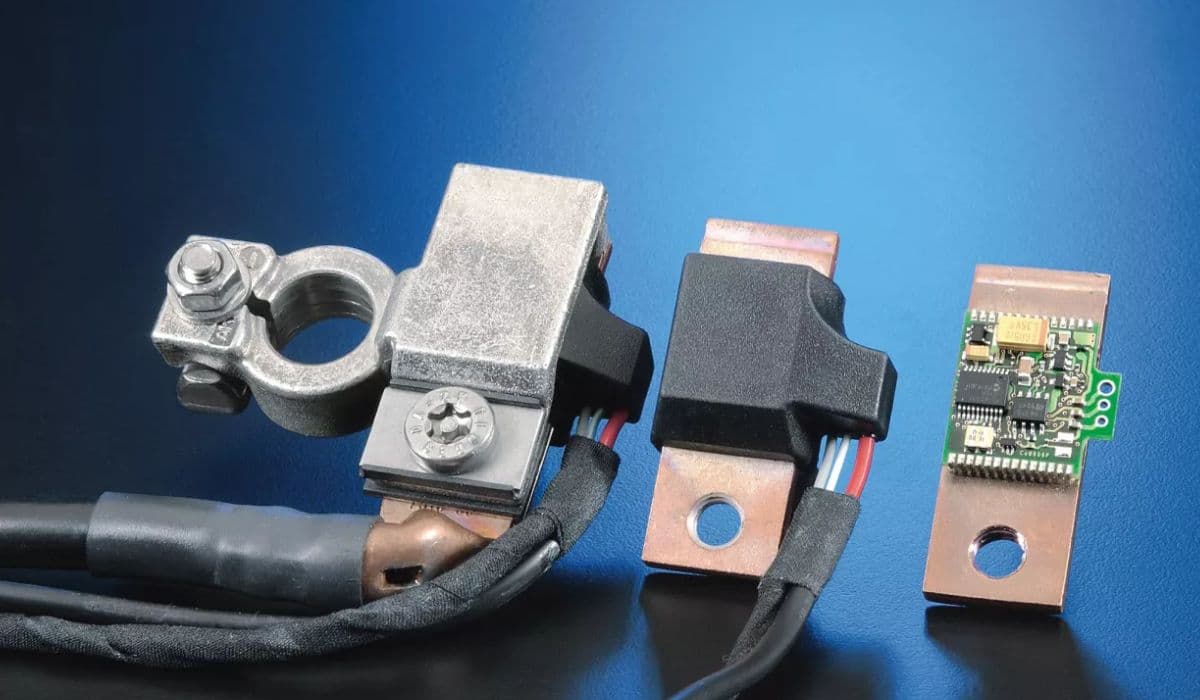

How to replace IBS battery sensor false errors BMW

13.12.2025 13:06

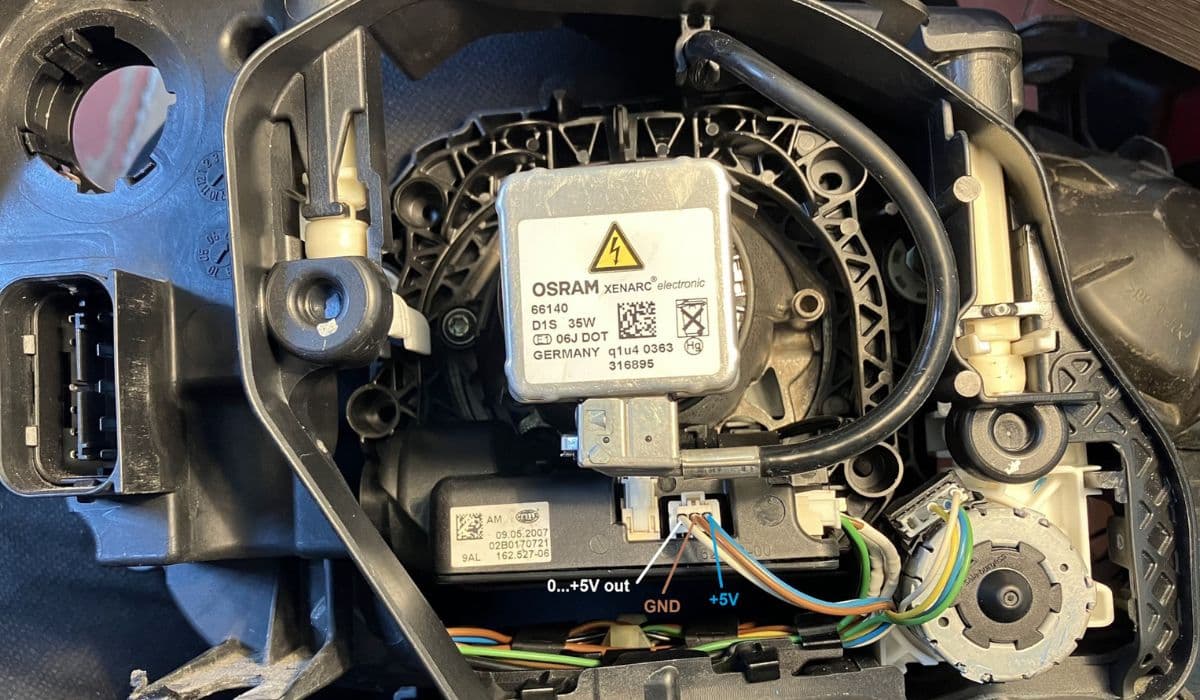

How to fix adaptive headlight malfunction (AHL errors) BMW

13.12.2025 13:00

How to replace control arm bushings (front thrust arms) BMW

13.12.2025 12:55

How to fix charge pipe failure on tuned BMW M3/M4

13.12.2025 12:49