How to fix DSC/ABS wheel speed sensor faults BMW

Modern BMW models rely on a sophisticated network of sensors and control modules to deliver precise braking, stability, and traction performance. The DSC (Dynamic Stability Control) and ABS (Anti-lock Braking System) systems constantly monitor wheel speeds to prevent skids, lockups, and loss of control. When a wheel speed sensor fails or sends erratic signals, the entire system can trigger warnings, reduced functionality, and sometimes noticeable changes in driving behavior.

These faults rank among the most frequent issues BMW owners encounter with braking and stability electronics. Fortunately, many cases stem from straightforward problems with the wheel speed sensors themselves rather than expensive modules or hydraulic units.

Understanding Wheel Speed Sensors in BMW Vehicles

Wheel speed sensors (also called ABS sensors or pulse generators) detect rotational speed at each wheel. They work by reading a toothed ring (tone ring or reluctor ring) attached to the wheel hub, CV joint, or axle. As the ring spins, it creates magnetic pulses that the sensor converts into an electrical signal sent to the DSC/ABS control unit.

BMW typically uses inductive or Hall-effect sensors:

Inductive types generate their own voltage through magnetic field changes.

Hall-effect sensors require power supply and produce a digital square wave signal.

The DSC module compares signals from all four wheels to detect slip, understeer, oversteer, or impending lockup. A mismatch or missing signal triggers fault codes and illuminates warning lights.

Common Symptoms of Faulty Wheel Speed Sensors

Recognizing the signs early helps avoid driving with compromised safety systems. Typical indicators include:

Illuminated ABS, DSC, brake, and sometimes 4x4/xDrive warning lights on the dashboard.

Yellow triangle with exclamation mark or "DSC malfunction" message in the iDrive display.

Loss of traction control intervention, making the car feel twitchy on slippery surfaces.

Reduced engine power or limp mode in some cases, as the system limits throttle to prevent instability.

Speedometer fluctuations or complete failure (especially if the left rear sensor is affected).

Pulsing brakes or unexpected activation during normal driving.

Intermittent faults that appear after hitting potholes, driving through deep water, or in cold/wet conditions.

These symptoms often start with one sensor but can cascade as the module detects inconsistencies across wheels.

Diagnosing Wheel Speed Sensor Issues Step by Step

Accurate diagnosis prevents unnecessary part replacement. Follow this logical sequence:

Scan for fault codes using a BMW-compatible diagnostic tool (such as ISTA, INPA, Carly, or advanced OBD scanners). Common codes include:

5DCx series for signal faults.

Implausible wheel speed signals.

No signal received from specific wheels.

Observe live data: Compare wheel speeds while driving or spinning wheels on a lift. A faulty sensor shows zero, erratic, or implausible readings compared to others.

Inspect visually: Raise the vehicle and check each sensor for damage, corrosion, or debris buildup. Look at the tone ring for cracks, missing teeth, rust, or scoring.

Test wiring and connectors: Disconnect the sensor plug and check for corrosion, bent pins, or water ingress. Measure resistance across sensor pins (typically 1-2 kΩ for inductive types) and check for shorts to ground.

Road test carefully: Note if faults appear only above certain speeds or during turns, which can point to wiring chafing or tone ring issues.

Intermittent problems often trace back to loose wiring, corroded connectors, or tone rings damaged by bearing wear.

Step-by-Step Guide to Replacing a Wheel Speed Sensor

Sensor replacement is a manageable DIY task on most BMW models, requiring basic tools and about 30-90 minutes per wheel.

Preparation

Park on a level surface and engage the parking brake.

Gather tools: jack and stands, lug wrench, 5mm hex (Allen) key, torque wrench, flathead screwdriver, electrical cleaner, and dielectric grease.

Disconnect the battery negative terminal if working near electronics (recommended for some models).

Front Wheel Speed Sensor Replacement

Loosen lug bolts and jack up the front, securing on stands. Remove the wheel.

Locate the sensor on the steering knuckle near the hub.

Disconnect the electrical connector (press the tab and pull gently).

Remove the 5mm hex bolt securing the sensor.

Carefully twist and pull the sensor out (use penetrating oil if stuck; avoid excessive force).

Clean the mounting hole and tone ring surface.

Install the new sensor: insert fully, secure with bolt (torque to spec, usually 8-10 Nm), route wiring through original clips.

Reconnect the plug and ensure no strain on the harness.

Rear Wheel Speed Sensor Replacement

Jack up the rear and remove the wheel.

The sensor sits in the wheel bearing housing or near the differential (xDrive models differ slightly).

Remove any splash shield or liner sections if needed (clips or small bolts).

Disconnect the connector (often tucked behind the liner).

Remove the retaining bolt and extract the sensor.

Clean thoroughly and install the replacement in reverse order.

Reassemble shields and torque bolts properly.

After installation, reconnect the battery, clear codes, and perform a test drive. Some systems self-calibrate; others may need a steering angle sensor reset or module adaptation via diagnostics.

Additional Causes and Related Components to Check

While sensors cause most issues, don't overlook these related culprits:

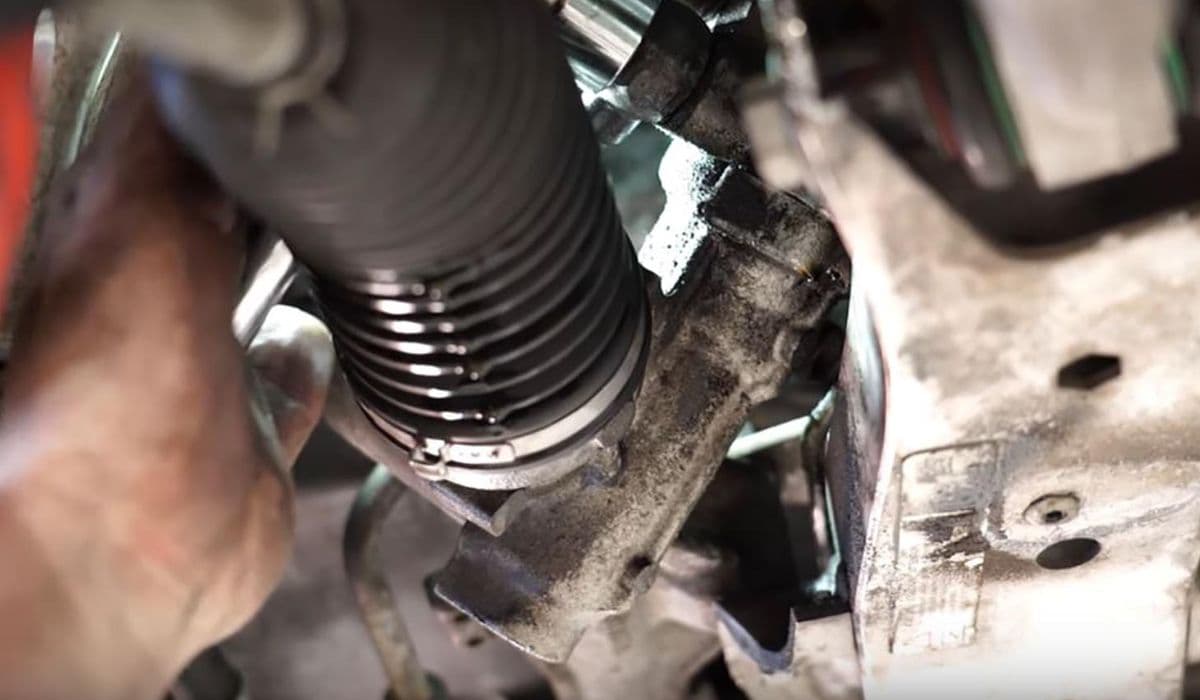

Damaged tone rings: Cracked, corroded, or debris-covered rings on CV joints or hubs disrupt signals—often requiring hub or axle replacement.

Wheel bearing wear: Excessive play moves the tone ring out of alignment, triggering faults.

Wiring harness damage: Chafing near suspension components or corrosion in connectors leads to intermittent signals.

Connector issues: Water intrusion or poor contact—clean with electrical spray and apply grease.

Rare cases: Faulty ABS/DSC module, low system voltage, or steering angle sensor misalignment (try lock-to-lock steering to recalibrate).

Always address tone ring or bearing problems simultaneously if discovered.

Preventing Future Wheel Speed Sensor Failures

Proactive maintenance extends sensor life significantly:

Regularly clean wheel wells to remove brake dust, salt, and debris.

Inspect sensors and tone rings during brake jobs or tire rotations.

Avoid deep puddles and aggressive off-road driving that splashes contaminants.

Check wiring routing to prevent rubbing against moving parts.

Use dielectric grease on connectors during reassembly for moisture protection.

By staying vigilant with these simple habits, you minimize the risk of recurring faults.

Your BMW's DSC and ABS systems depend on reliable wheel speed data for optimal performance and safety. Addressing sensor issues promptly restores full functionality and peace of mind on the road.

More from BMW

How to replace run-flat tires and reset TPMS BMW

13.12.2025 13:40

How to fix electronic steering rack clunk BMW

13.12.2025 13:35

How to fix crankcase ventilation (PCV) valve heater BMW

13.12.2025 13:13

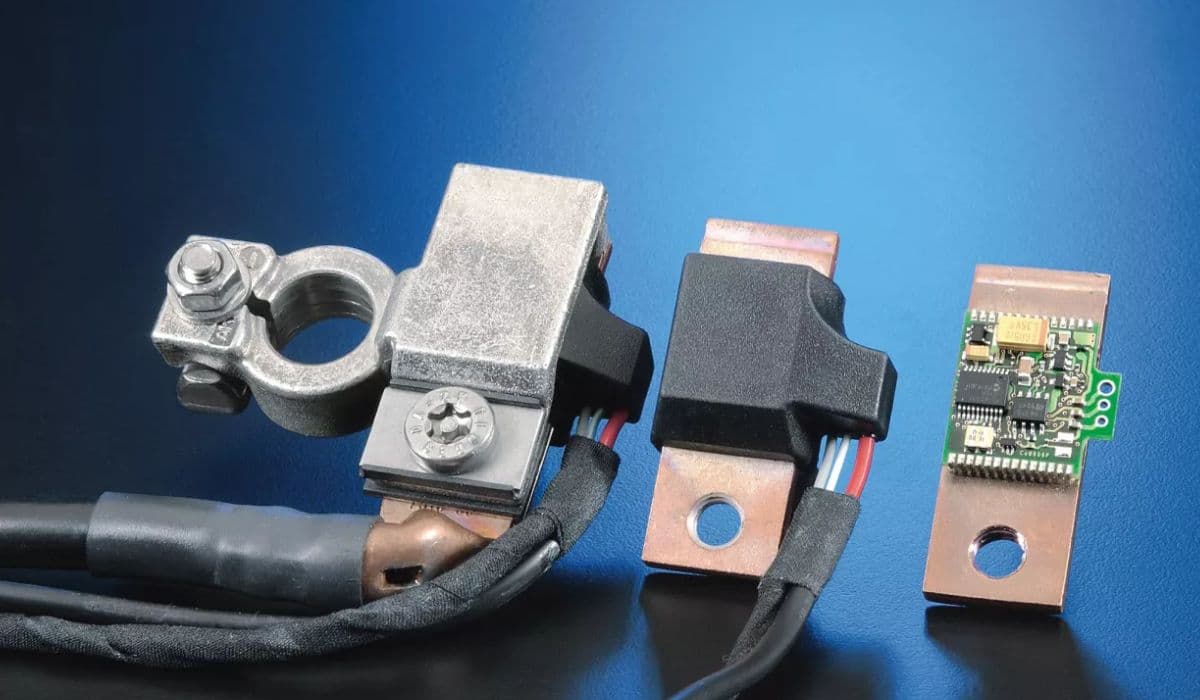

How to replace IBS battery sensor false errors BMW

13.12.2025 13:06

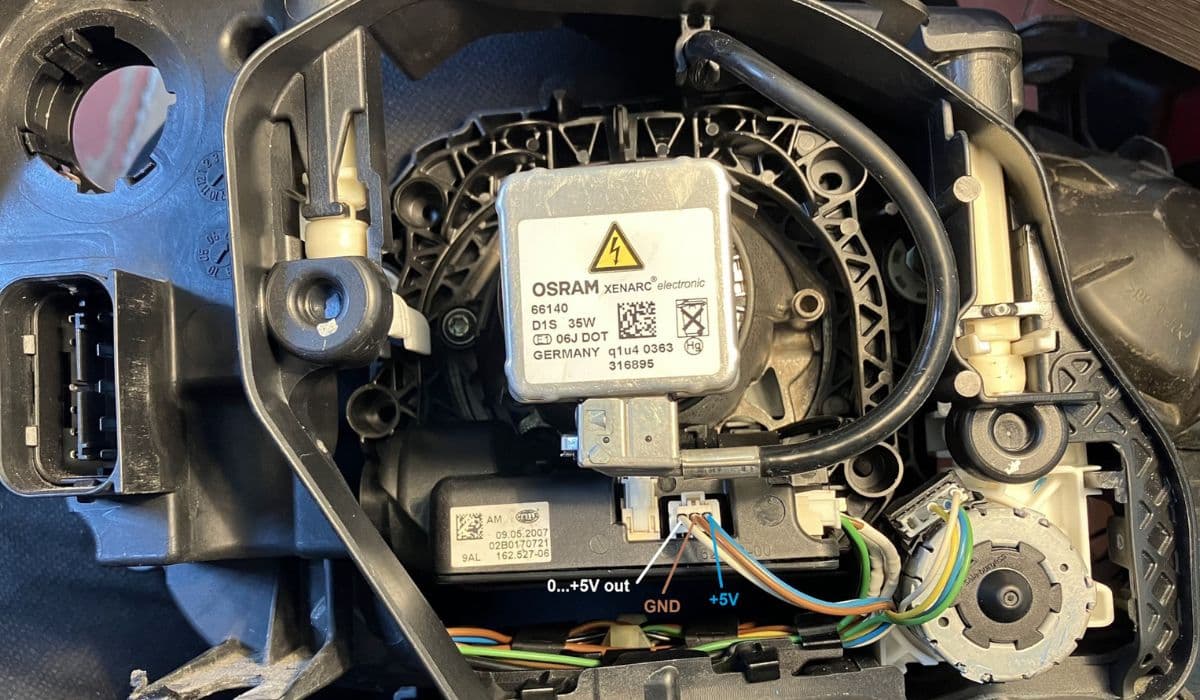

How to fix adaptive headlight malfunction (AHL errors) BMW

13.12.2025 13:00