How to replace turbo oil lines BMW (N63 hot-V engines)

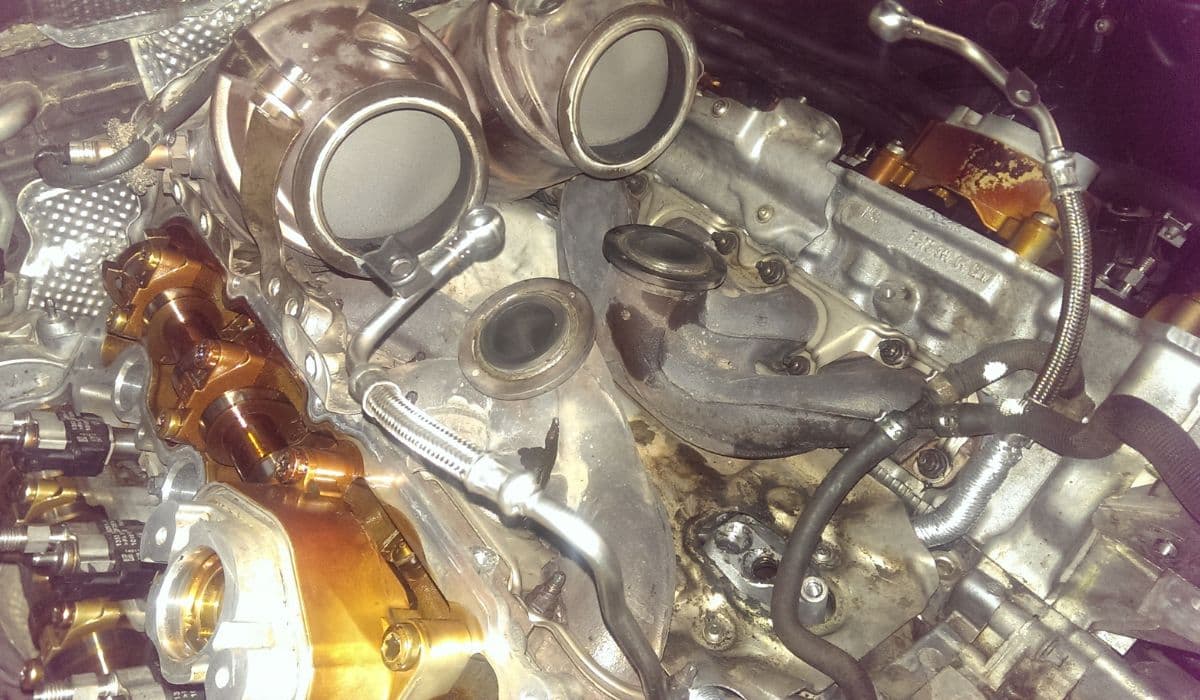

The BMW N63 engine, with its distinctive hot-V twin-turbo layout, delivers exhilarating performance but comes with well-known maintenance challenges. Among the most frequent issues are problems with the turbo oil lines—both feed (supply) and return (drain) lines. Extreme heat in the engine valley causes gaskets to degrade, lines to clog from coked oil, or seals to fail, resulting in leaks that drip into the bellhousing area or create burning oil smells. Replacing these lines restores proper lubrication to the turbos, prevents catastrophic failures, and keeps the engine running smoothly.

This guide focuses on a thorough, practical approach to replacing the turbo oil feed and return lines on N63 hot-V engines. While advanced DIY enthusiasts can tackle this job, it demands patience, specialized tools, and a clean workspace.

Understanding the N63 Turbo Oil System Layout

In the N63's hot-V configuration, the turbos sit nestled between the cylinder banks, right above the exhaust manifolds. This design minimizes lag but exposes components to intense heat.

Oil feed lines deliver pressurized oil from the engine block to each turbo for bearing lubrication and cooling.

Oil return lines drain used oil back to the sump, often through a central return cover (also called the oil drain block or valley pan interface).

The return cover gasket frequently fails first due to thermal cycling, allowing oil to leak downward.

Feed lines can develop internal restrictions from carbon buildup or external leaks at fittings.

Common failure signs include oil spots under the transmission bellhousing, a persistent burning oil odor, low oil pressure warnings, or excessive crankcase pressure.

Essential Tools and Preparation Steps

Success depends on having the right equipment and a methodical disassembly process.

Torx bits (T30, T40, T45, T55) and sockets

Allen/hex bits and wrenches

Long breaker bar and extensions

Magnetic pickup tool and flexible claw grabber

Torque wrench (essential for precise tightening)

New gaskets, O-rings, and crush washers for every connection

High-temperature RTV silicone (for certain gaskets if recommended)

Shop rags, drain pans, and degreaser

Preparation is critical:

Park on a level surface and let the engine cool completely (several hours minimum).

Disconnect the negative battery terminal to prevent electrical surprises.

Drain engine oil and coolant if accessing lower components.

Remove engine covers, air intake boxes, and any obstructing heat shields early.

Accessing the Turbo Oil Lines – Step-by-Step Disassembly

Reaching the lines requires significant disassembly due to the tight engine bay.

Remove the alternator and its bracket for better top access to the valley.

Disconnect and set aside accessory belts using a long breaker bar on the tensioner.

Unbolt and carefully remove lambda (oxygen) sensors with a dedicated socket to avoid damage.

Detach intercooler piping, CCV hoses, and vacuum lines methodically, labeling everything.

Loosen exhaust downpipes and heat shields around the turbos (these bolts often seize—penetrating oil helps).

Support the turbos and unbolt them from the exhaust manifolds (new manifold gaskets are highly recommended).

With turbos loosened, access the oil feed lines at the block and turbo inlets.

For return lines, separate the turbos from the central return cover (usually two small Torx screws per turbo at the base).

Removing the Old Turbo Oil Feed and Return Lines

Once exposed, removal requires care to avoid contaminating passages.

Disconnect feed lines at the block (often banjo bolts with crush washers—expect oil spillage).

Carefully unscrew lines from the turbo housings; inspect for internal carbon buildup.

For return lines, detach from the turbo outlets and the central return cover.

Remove the return cover itself if replacing the gasket (torque specs are low—typically around 10 Nm for cover bolts).

Clean all mating surfaces thoroughly with brake cleaner; avoid debris entering oil passages.

Inspect removed lines: clogged feed lines often show hardened oil residue, while return lines may have cracked fittings or failed O-rings.

Installing New Turbo Oil Lines – Best Practices

Quality replacement parts make a huge difference—choose updated designs with improved seals.

Install new crush washers or gaskets on every banjo bolt and fitting.

Route feed lines without kinks or sharp bends to ensure unrestricted flow.

Attach lines to turbos first, then to the block, hand-tightening before torquing.

For return lines, position the new cover with fresh gasket (apply high-temp sealant sparingly if specified).

Reattach turbos to the return cover using new hardware.

Torque all fasteners precisely: feed line banjo bolts often require 25-30 Nm, return cover bolts lower.

Double-check clearances—lines must not contact hot exhaust components.

Reassembly and Final Checks

Reverse disassembly carefully, torquing everything to spec.

Reinstall exhaust components with new gaskets to prevent leaks.

Refit alternator, belts, sensors, and intake tract.

Reconnect battery, refill oil and coolant.

Start the engine and let it idle, watching for leaks at all new connections.

Check oil pressure with a gauge if possible.

Take a short test drive, then re-inspect after cooling.

Pay special attention to turbo cooldown: the auxiliary coolant pump should run post-shutdown to prevent heat soak issues that accelerate future failures.

Common Pitfalls and Pro Tips

Even experienced mechanics encounter surprises on N63 jobs.

Dropped bolts vanish into the valley—magnetic tools save hours.

Seized exhaust bolts may require heat or cutting—plan extra time.

Old heat shields often break; replacements improve longevity.

Always replace related gaskets (manifold, turbo outlet) during the job.

After replacement, monitor oil level closely for the first few hundred miles.

Mastering turbo oil line replacement on the N63 transforms a frustrating leak into a reliable, powerful engine once again. With attention to detail and proper torque values, the hot-V turbos regain their full potential.

More from BMW

How to fix crankcase ventilation (PCV) valve heater BMW

13.12.2025 13:13

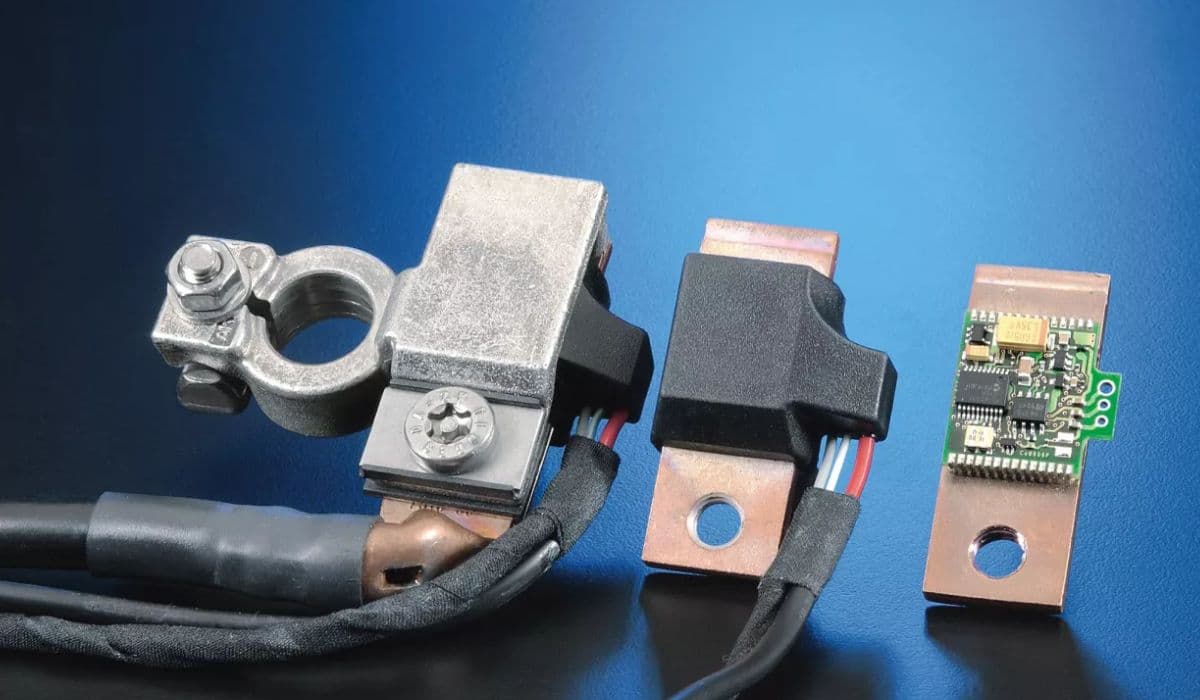

How to replace IBS battery sensor false errors BMW

13.12.2025 13:06

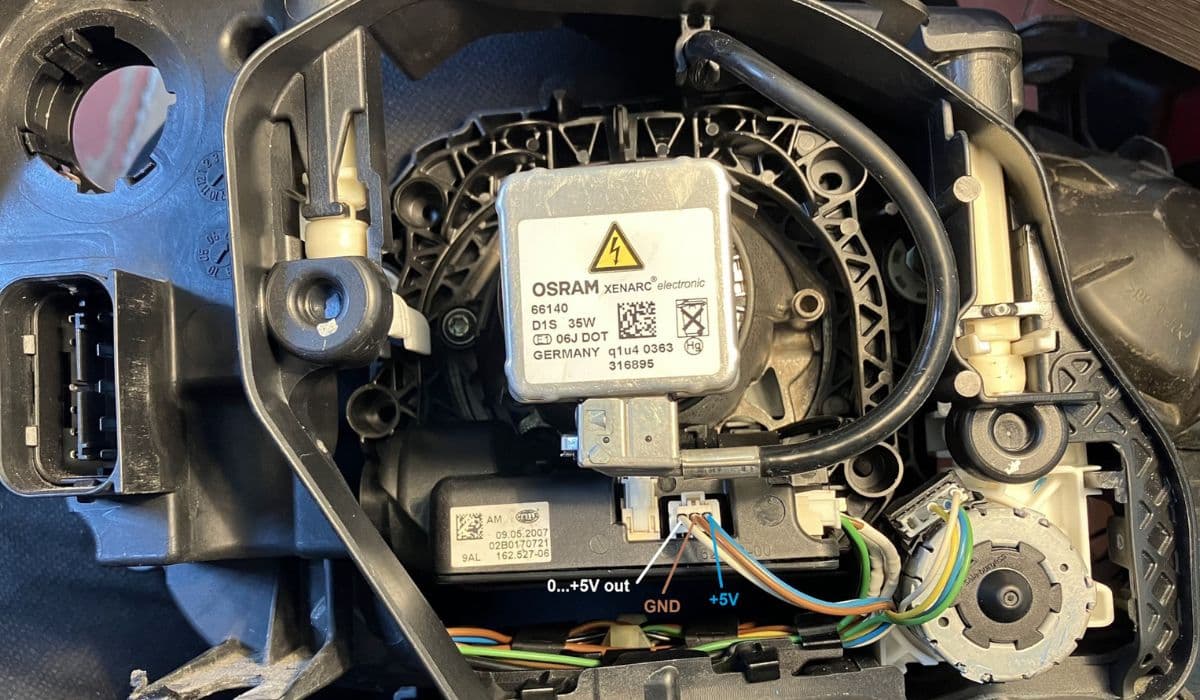

How to fix adaptive headlight malfunction (AHL errors) BMW

13.12.2025 13:00

How to replace control arm bushings (front thrust arms) BMW

13.12.2025 12:55

How to fix charge pipe failure on tuned BMW M3/M4

13.12.2025 12:49