How to replace control arm bushings (front thrust arms) BMW

Front thrust arms, often called tension struts or thrust rods in BMW terminology, play a critical role in the front suspension geometry of many models. These longitudinal arms connect the steering knuckle to the subframe and primarily manage fore-aft forces during braking, acceleration, and road impacts. Their bushings absorb vibrations and allow controlled movement, but over time they degrade, leading to noticeable changes in driving dynamics.

Replacing the bushings in these thrust arms can restore precise steering feel, eliminate unwanted noises, and prevent accelerated wear on tires and other suspension components. While many owners opt to replace the entire thrust arm assembly (with pre-installed bushings), pressing out and installing new bushings alone is a viable and cost-effective option for those equipped with the right tools and patience.

This detailed guide walks through the process step by step, focusing on a thorough DIY approach suitable for models where thrust arms feature replaceable bushings.

Understanding Thrust Arm Bushings and Why They Fail

Thrust arm bushings endure constant torsional and compressive loads. The large hydraulic-style bushing at the subframe end often features a voided rubber design to dampen vibrations while maintaining alignment.

Common failure symptoms include:

Steering wheel shimmy or shudder, especially under light braking or at specific speeds

Clunking or clicking noises from the front end during acceleration, deceleration, or direction changes

Loose or vague steering response with delayed turn-in

Uneven tire wear, particularly cupping on inner edges of front tires

Visible cracks, fluid leakage (from hydraulic-filled bushings), or collapsed rubber in the bushing

Early detection prevents secondary damage like ball joint wear or subframe stress. Inspect bushings visually for tears or separation, and test by prying the arm while the vehicle is safely elevated—excessive play signals replacement time.

Tools and Materials Needed

Gather quality tools before starting to avoid interruptions:

Floor jack and sturdy jack stands (or lift for easier access)

Wheel chocks

Socket set (including 18mm, 21mm, 22mm sockets and wrenches)

Torque wrench (essential for final tightening)

Breaker bar for stubborn bolts

Hydraulic press (12-20 ton recommended) with appropriate adapters/cups for bushing removal and installation

Pry bar or large screwdriver

Penetrating oil (for rusted fasteners)

New bushings (OEM-style or upgraded polyurethane for better longevity)

New self-locking nuts where applicable (some bolts are torque-to-yield)

Nitrile gloves and safety glasses

A bushing press kit designed for BMW applications simplifies the job significantly, as generic tools may damage the arm bore.

Safety Precautions and Vehicle Preparation

Safety comes first when working under a vehicle:

Park on a flat, level surface and engage the parking brake

Chock rear wheels

Disconnect the battery if working near airbags or electronics (optional but recommended)

Never rely solely on a jack—always use rated jack stands

Wear eye protection and gloves to handle grease and sharp edges

Raise the front of the vehicle and remove both front wheels for full access. Support the hub/knuckle assembly with a jack to prevent straining brake lines or CV joints during arm removal.

Step-by-Step Removal of Thrust Arms

Accessing the thrust arms usually requires partial disassembly:

Spray penetrating oil on all bolts (subframe mount and knuckle ball joint) and let it soak

Remove the nut securing the thrust arm ball joint to the steering knuckle (often 21mm or 22mm)—use a breaker bar if seized

If the ball joint stud spins, employ a hex key in the end or separate it with a pickle fork or ball joint separator tool

Support the knuckle/hub to avoid stressing the strut or brake line

Remove the large bolt/nut at the subframe end (typically 18-22mm)—this bolt passes through the bushing sleeve

Carefully maneuver the thrust arm out; on some models with xDrive, slight axle repositioning may help gain clearance

Inspect the removed arm for ball joint play—if excessive, consider full arm replacement instead of just bushings.

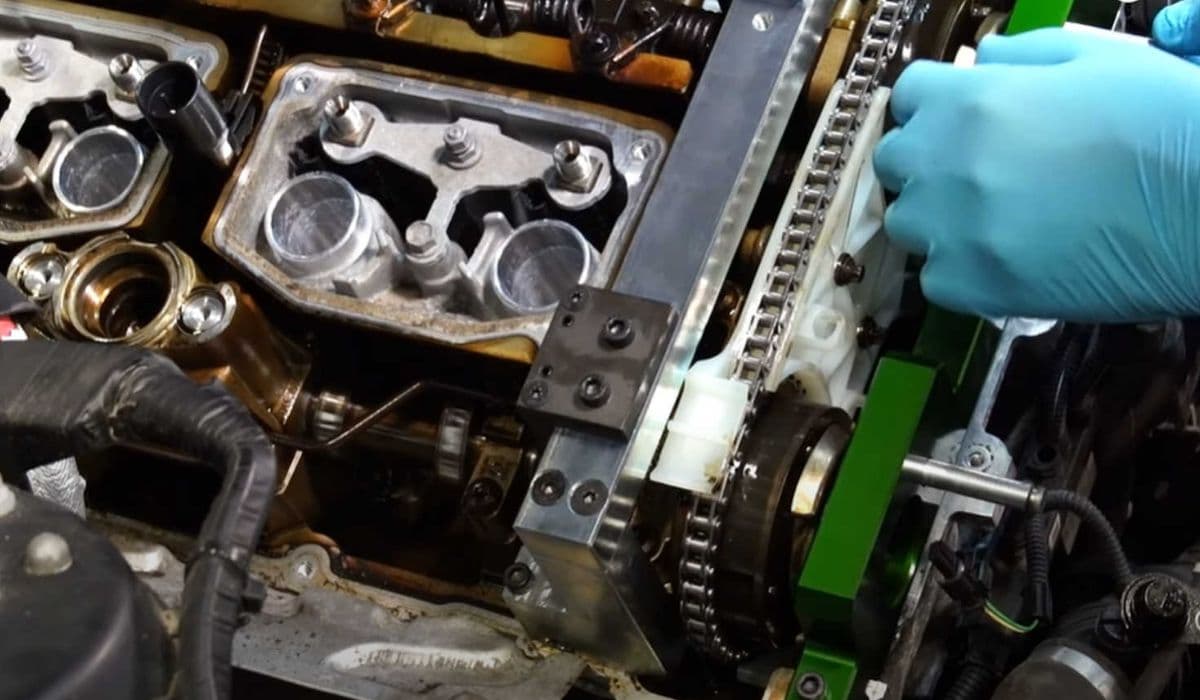

Pressing Out the Old Bushings

With the arm secured in a vise or on a workbench:

Identify orientation: most BMW thrust arm bushings have a specific “clocking” (alignment) with voids or markings facing a particular direction

Position the arm in the hydraulic press with a receiver cup that supports the arm bore without deforming it

Use a driver/adapter slightly smaller than the outer bushing diameter to press the old bushing out smoothly

Apply steady pressure—never hammer, as it risks cracking the aluminum arm

Clean the bore thoroughly after removal, removing old rubber residue and corrosion with a wire brush or emery cloth

Note: BMW thrust arm bores are typically designed for one-time bushing replacement; repeated pressing enlarges the hole and compromises fit.

Installing New Bushings Correctly

Proper installation is crucial for performance and longevity:

Apply a thin layer of silicone-based grease (not petroleum-based, to avoid rubber degradation) to the outer surface of the new bushing

Align the new bushing precisely according to factory markings or voids—incorrect clocking causes binding, noise, or uneven wear

Use the press with an installation cup that matches the bushing flange diameter

Press slowly and evenly until fully seated—listen for the “pop” as it seats

Double-check alignment after pressing; the bushing should sit flush without twisting

Polyurethane upgrades offer sharper response and longer life but transmit more road feedback—choose based on your driving style.

Reinstallation and Torque Specifications

Reverse the removal process with attention to detail:

Position the thrust arm back into the subframe first, starting the large bolt by hand

Reconnect the ball joint end to the knuckle and install a new self-locking nut finger-tight

Lower the vehicle to the ground so suspension is at normal ride height

With wheels installed and vehicle loaded (or use a floor jack under the knuckle to simulate ride height), torque all fasteners to factory specs—typically the subframe bolt requires high torque (often 100-150+ Nm range, plus angle) and the ball joint nut around 60-100 Nm

Re-check all connections after a short test drive

Tightening bushings under load prevents premature tearing from pre-loaded torsion.

Post-Installation Tips and Final Checks

After completing both sides:

Perform a gentle test drive, listening for new noises and feeling for improved steering precision

Check wheel alignment—worn bushings often cause misalignment, and replacement warrants a fresh four-wheel alignment

Re-inspect after 50-100 miles for any settling or loosening

Consider complementary maintenance like refreshing related bushings (lower control arms, sway bar links) while access is easy

Mastering this procedure transforms the front-end feel of your BMW, delivering tighter handling and confidence-inspiring stability that makes every drive more engaging. With careful execution, the results rival professional shop quality while deepening your understanding of the chassis dynamics that define BMW driving character.

More from BMW

How to fix charge pipe failure on tuned BMW M3/M4

13.12.2025 12:49

How to replace transfer case actuator BMW (xDrive grinding noise)

13.12.2025 08:45

How to fix FRM footwell module lighting issues BMW

13.12.2025 08:40

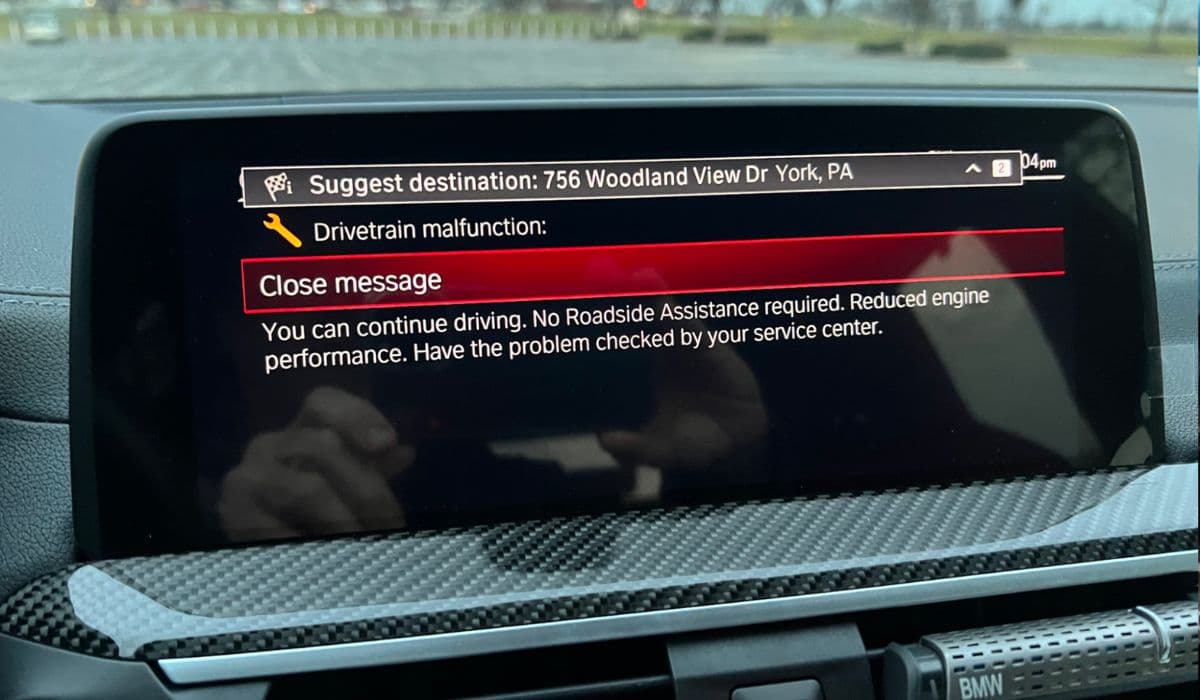

How to fix drivetrain malfunction error BMW (2025 models)

13.12.2025 06:24

How to replace thermostat and coolant flange BMW

13.12.2025 05:34