How to fix emissions light and software errors (BMW X5)

The emissions light, often appearing as the check engine light on your BMW X5 dashboard, signals potential issues within the engine or exhaust system that affect harmful gas output. This warning can stem from minor oversights or more complex faults, impacting performance, fuel efficiency, and the vehicle's ability to meet environmental standards. Addressing it promptly prevents escalation into bigger problems, while software errors in the engine control module can compound these issues by misinterpreting sensor data or triggering false alerts.

Modern BMW X5 models rely heavily on sophisticated electronics to monitor and optimize emissions. When the light illuminates, it usually means the onboard diagnostics have detected an anomaly. Ignoring it might lead to reduced power, rough idling, or even limp mode activation. Understanding the root causes empowers owners to tackle repairs effectively, whether through simple checks or targeted interventions.

Understanding the Emissions Light in BMW X5

The emissions-related check engine light activates when the system detects deviations from optimal air-fuel mixtures or exhaust treatment. In the X5, this light ties directly to components that manage combustion byproducts.

Common triggers include sensor malfunctions that throw off the engine's balance, leading to incomplete burning of fuel. Over time, this excess can overwhelm downstream parts designed to clean the exhaust.

Loose or damaged fuel cap allowing vapors to escape

Faulty oxygen sensors misreading exhaust gases

Clogged mass airflow sensor affecting intake measurements

Vacuum leaks disrupting pressure in the intake system

Issues with the evaporative emissions control system

These faults often start small but can cascade, highlighting the interconnected nature of the X5's powertrain.

Common Causes of Emissions Light Activation

Several recurring issues plague BMW X5 owners, particularly those related to the exhaust and fuel delivery systems.

Oxygen sensors play a pivotal role by measuring unburned oxygen levels before and after the catalytic converter. When they degrade, the engine control unit receives inaccurate data, causing rich or lean running conditions that spike emissions.

Catalytic converters themselves can suffer from contamination or internal breakdown, especially if upstream problems like misfires go unresolved. This component neutralizes toxic gases, and its inefficiency directly triggers the light.

Dirty or failing mass airflow sensor leading to improper fuel metering

Vacuum hose cracks causing erratic idle and increased emissions

Spark plug wear or ignition coil failures resulting in misfires

Exhaust gas recirculation valve sticking, recirculating too much or too little gas

Diesel variants may encounter glow plug system faults, where pre-heating elements fail, complicating cold starts and raising particulate output.

Diagnosing the Problem Step by Step

Accurate diagnosis forms the foundation of any successful repair. Start with an OBD-II scanner compatible with BMW protocols to retrieve specific fault codes.

These codes pinpoint the affected circuit or component, narrowing down possibilities immensely.

Begin by inspecting visible elements:

Tighten the gas cap and clear temporary codes to see if the light returns

Check for obvious vacuum leaks by listening for hissing sounds

Examine wiring harnesses near hot exhaust parts for melting or fraying

For deeper analysis, monitor live data streams from sensors while the engine runs. Fluctuating readings outside normal ranges often indicate a failing part.

In cases of intermittent issues, drive cycles help recreate conditions, as some faults only log under specific loads or temperatures.

Professional tools like BMW-specific scanners reveal shadow codes or adaptation values that generic readers miss.

Fixing Common Emissions-Related Faults

Many emissions light triggers resolve through targeted replacements or cleaning.

Oxygen sensor faults demand swapping the defective unit—pre-catalytic ones influence fuel trim, while post-catalytic monitor converter health.

Clean the mass airflow sensor with dedicated spray to restore accuracy

Replace cracked vacuum lines with OEM equivalents for proper sealing

Install fresh spark plugs if misfires contribute to the issue

Address evaporative system leaks by inspecting purge valves and charcoal canisters

For catalytic converter concerns, first rule out upstream causes, as a new converter won't last if sensors or combustion remain faulty.

Diesel owners facing glow plug errors often find relief by replacing the control module, a notorious weak point that fails and cascades faults across multiple plugs.

Addressing Software Errors and ECU Issues

Software glitches in the digital diesel electronics or engine control unit can mimic hardware failures or prevent proper communication.

Outdated firmware sometimes causes erroneous readings, leading to persistent lights even after physical repairs.

Authorized updates via diagnostic interfaces resolve many such anomalies by refining adaptation parameters.

In rare cases, ECU hardware degradation—such as internal connection failures—requires professional rebuilding or replacement.

Perform adaptations after component swaps to let the system relearn values

Clear stored faults and monitor for recurrence over several drive cycles

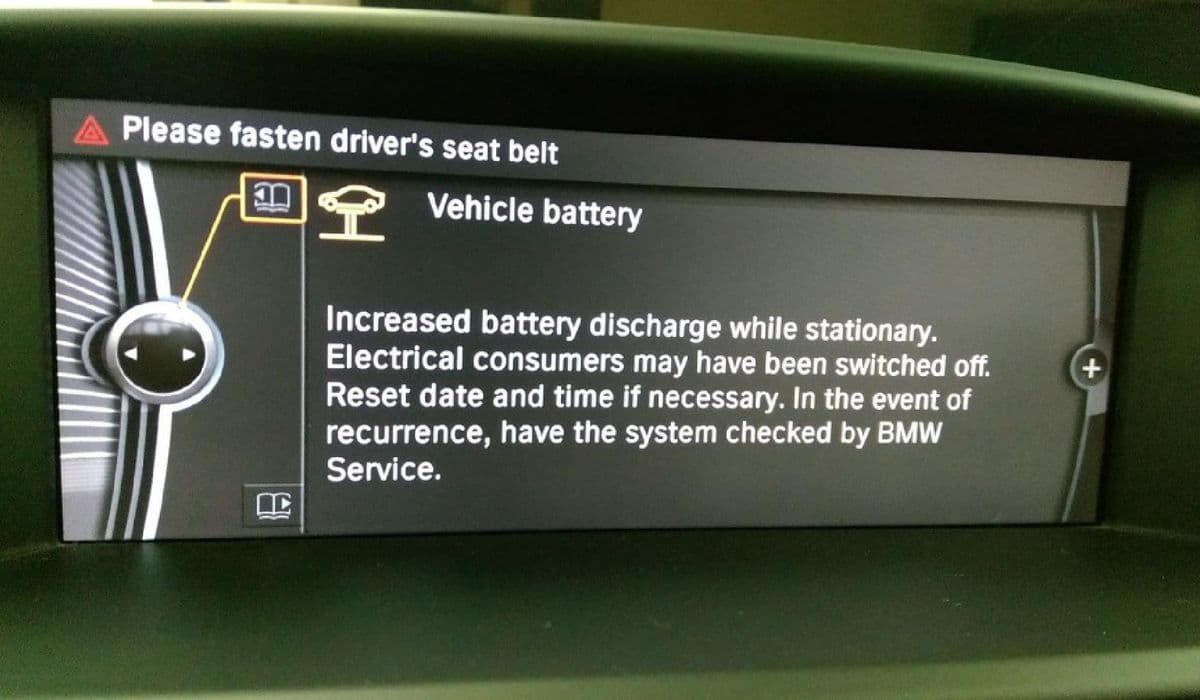

Check battery voltage, as low charge corrupts module data

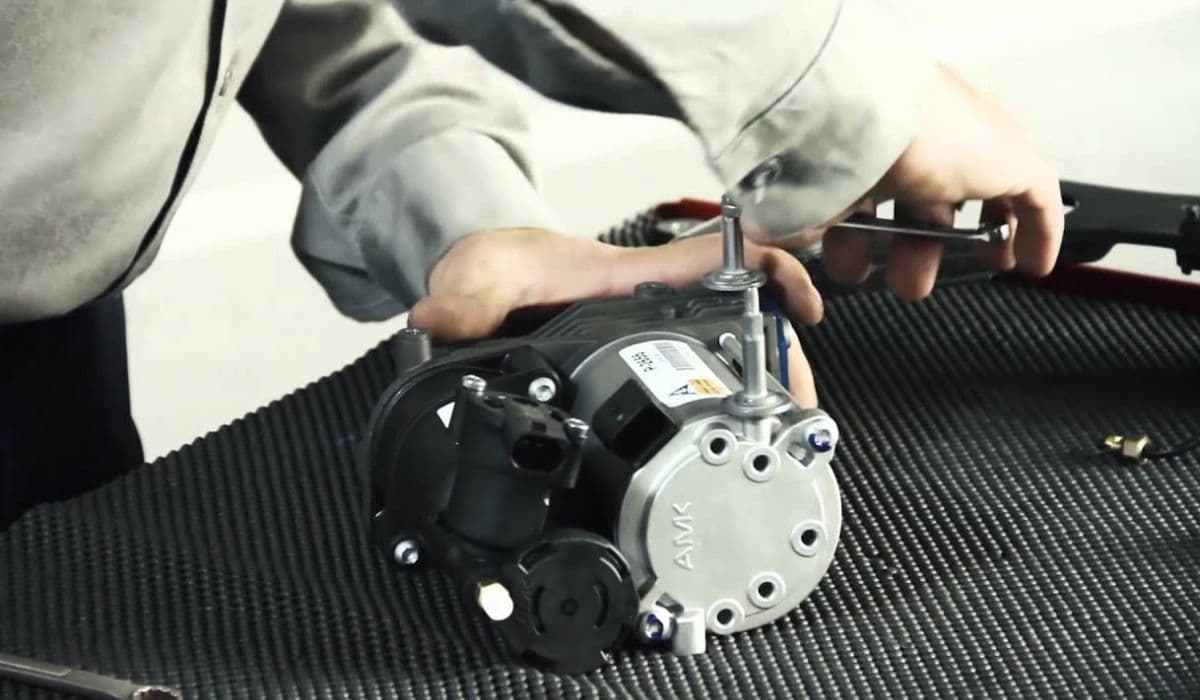

Valvetronic system errors in gasoline models, involving variable valve lift, may stem from eccentric shaft sensor drift or motor wear, often needing recalibration post-repair.

Resetting the Emissions Light Safely

Once the underlying fault clears, the light may extinguish after completing drive cycles that verify normal operation.

Manual resets via scanner ensure monitors run without re-triggering alerts.

Avoid disconnecting the battery, as it wipes adaptations and risks further issues.

Drive normally for 50-100 miles post-repair, allowing readiness monitors to set—this confirms the fix and prepares the vehicle for inspections.

If the light persists, revisit diagnostics, as pending codes might lurk.

Preventive Maintenance Tips for Long-Term Reliability

Regular upkeep minimizes emissions woes in the BMW X5.

Use quality fuel to prevent sensor contamination, and adhere to service intervals for sensor inspections.

Monitor for rough running or efficiency drops as early warnings

Keep the exhaust system free of impacts that damage converters

Ensure proper coolant levels to avoid overheating-related faults

Proactive scanning during routine maintenance catches brewing problems before the light appears.

By staying vigilant, owners enjoy the X5's dynamic performance without frequent dashboard interruptions.

More from BMW

How to fix starter-generator loose connection BMW

19.12.2025 16:00

How to fix high-voltage battery shutdown (BMW i4/iX recall)

14.12.2025 14:38

How to replace starter-generator connection BMW

14.12.2025 11:51

How to fix panoramic roof noise or leaks BMW

14.12.2025 07:56

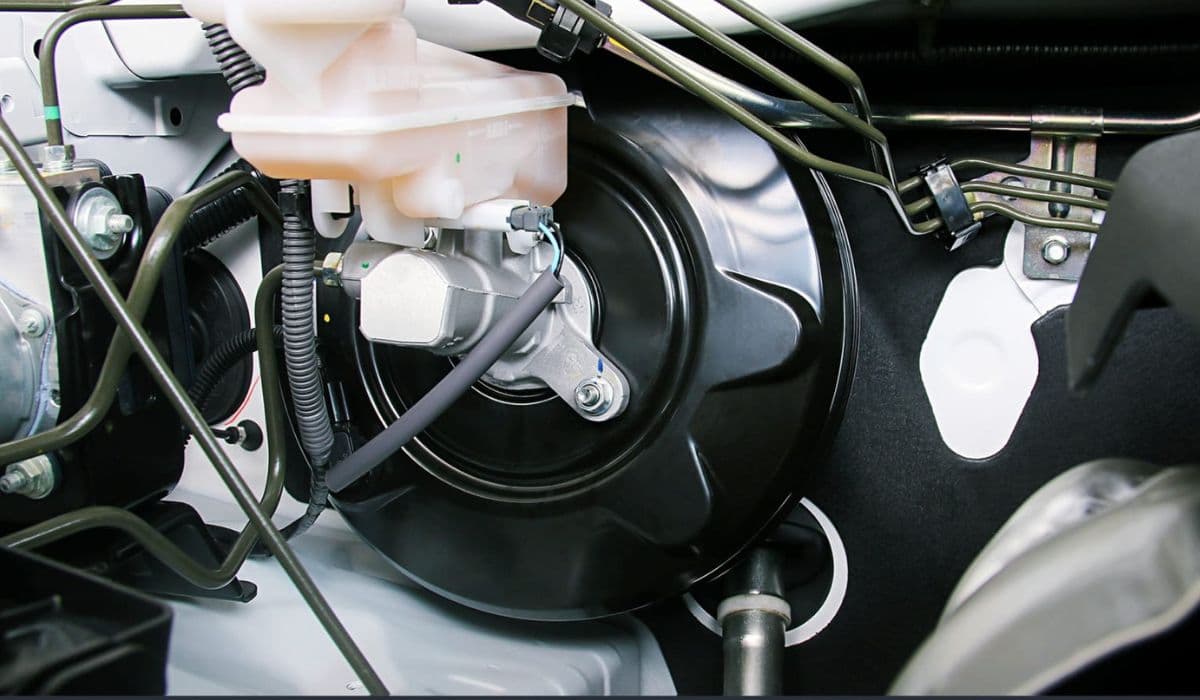

How to fix brake booster vacuum issues BMW

14.12.2025 06:06