How to replace starter-generator connection BMW

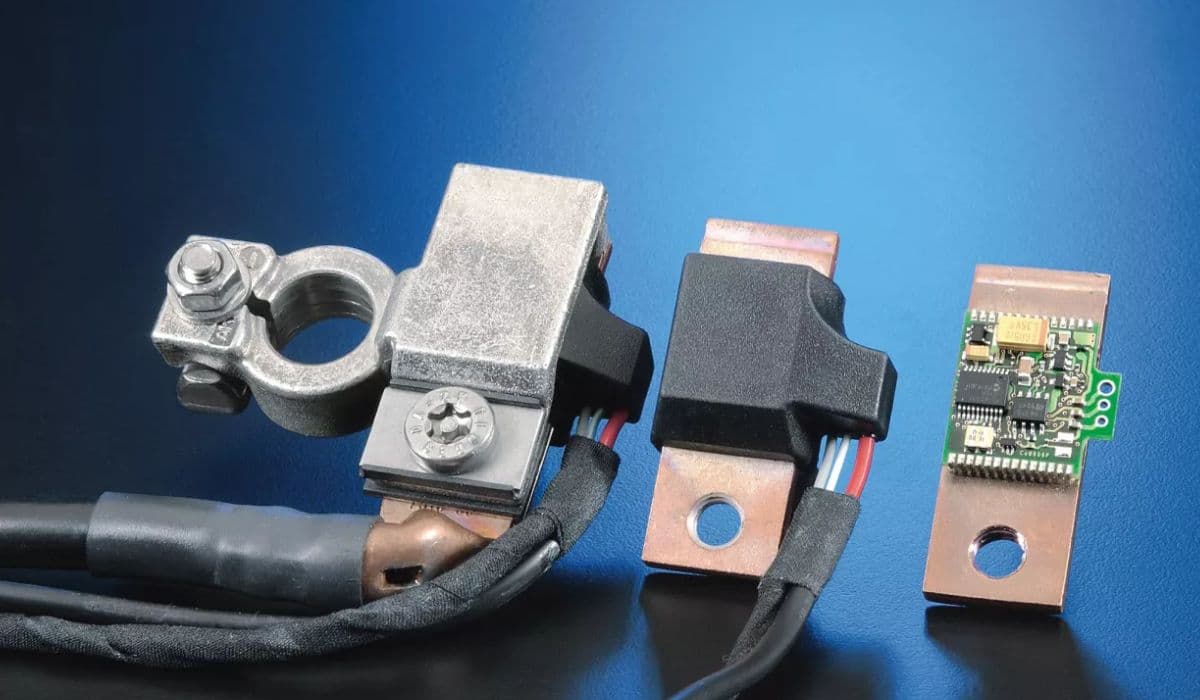

Modern BMW models equipped with mild-hybrid technology feature an integrated starter-generator (often called a 48V starter-generator or belt-driven starter-alternator). This compact unit combines starting the engine with generating power for the vehicle's electrical systems and battery charging. Over time, the electrical connection between the positive battery cable and the starter-generator can develop increased resistance, leading to poor performance, no-start conditions, or even localized overheating.

Replacing or properly servicing this critical connection requires attention to detail, proper tools, and strict safety practices. This guide walks you through the complete process step by step.

Understanding the Starter-Generator System in BMW

The starter-generator in many current BMWs is a belt-driven ISG (Integrated Starter Generator) that performs dual functions:

Delivers high-torque cranking power during engine start (including quick start-stop operation)

Generates electricity efficiently during driving, often supporting 48V mild-hybrid functions

The main electrical interface is typically a heavy-gauge positive cable that connects directly to a large stud or terminal on the starter-generator housing. A secure, low-resistance connection here is essential for reliable operation and safety.

Common symptoms that indicate connection problems include:

Intermittent no-start conditions

Clicking sounds without cranking

Burning smell near the engine bay

Warning lights related to battery or charging system

Reduced performance of start-stop system

Essential Safety Precautions Before Starting Work

Working on the starter-generator involves high-current connections and potentially 48V systems. Follow these safety rules religiously:

Park the vehicle on a level surface with the parking brake engaged

Allow the engine to cool completely

Disconnect the negative battery terminal first, then the positive

Wait at least 10–15 minutes for any residual voltage in capacitors to dissipate

Use insulated tools when working near live connections

Wear safety glasses and protective gloves

Never work alone — have someone nearby in case of emergency

Tools and Materials Needed

Gather these items before beginning:

Socket set (metric, including deep sockets)

Torque wrench (essential for proper tightening)

Combination wrenches

Trim removal tools

Battery terminal puller (optional but helpful)

Electrical contact cleaner

Dielectric grease

Wire brush or small sandpaper for cleaning terminals

New positive cable if damaged (recommended for best results)

Anti-corrosion compound for terminals

Step-by-Step Removal of the Old Connection

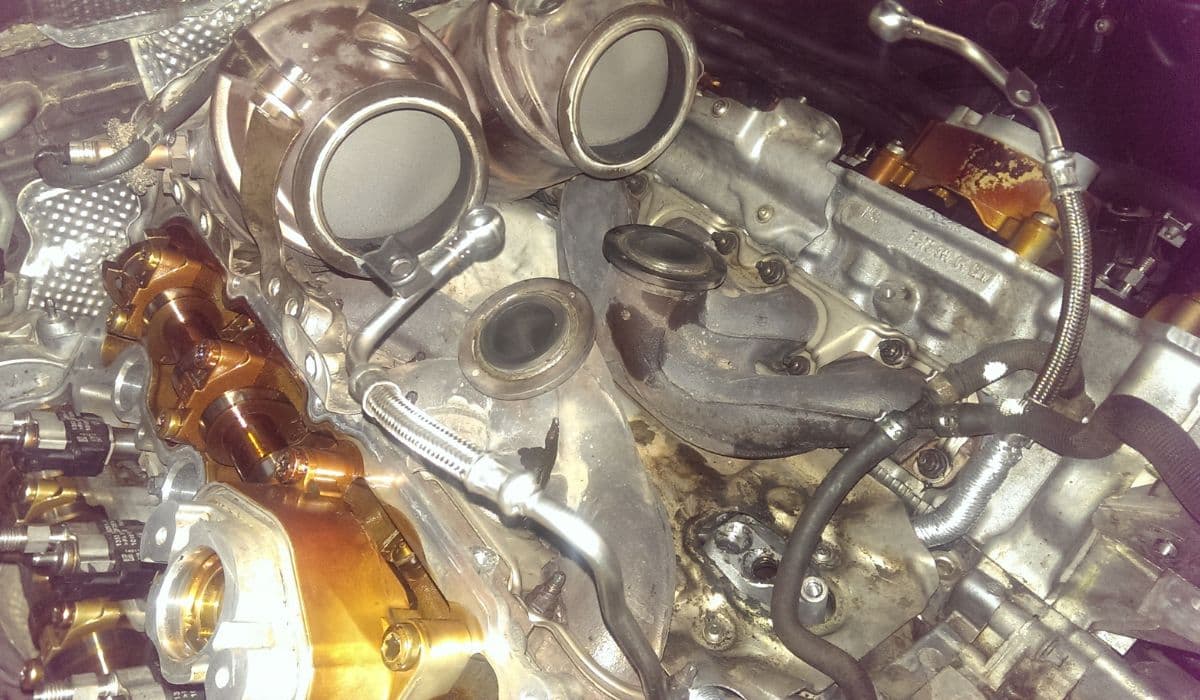

Accessing the starter-generator connection usually requires partial disassembly in the engine bay:

Remove the engine cover and any plastic trim pieces obstructing access

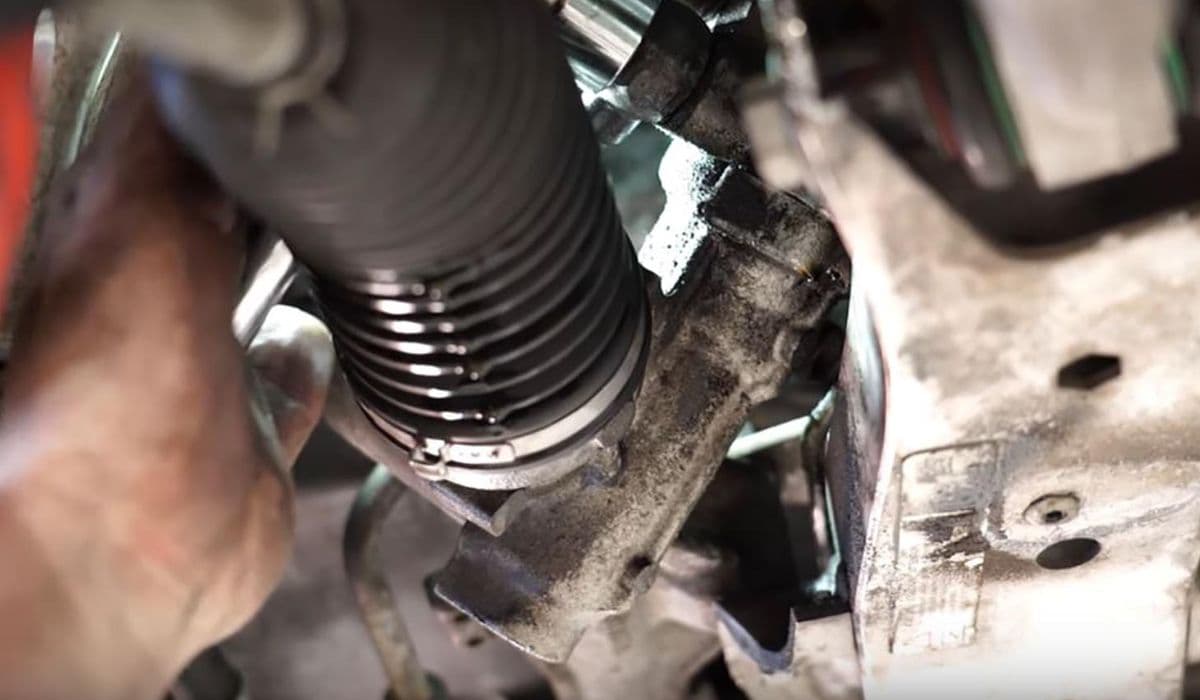

Locate the starter-generator — most commonly mounted on the front of the engine block, driven by the accessory belt

Identify the large positive power cable (usually red or covered in red protective sheath) attached to the starter-generator terminal

Carefully remove any protective covers or heat shields around the connection point

Loosen and remove the main nut securing the positive cable to the starter-generator stud (note the exact position of any washers or spacers)

Gently disconnect the cable — avoid bending or stressing the cable excessively

Inspect the terminal lug for signs of overheating (discoloration, melting, or corrosion)

Examine the stud on the starter-generator itself for thread damage or carbon buildup

Clean both mating surfaces thoroughly using electrical contact cleaner and a wire brush

Careful inspection at this stage often reveals the root cause — poor contact due to oxidation, loose fit, or heat damage.

Preparing the New Connection

Whether you're reusing the existing cable (after cleaning) or installing a new one, preparation is crucial:

If reusing the cable, clean the lug terminal until shiny metal is visible

Check cable integrity along its entire length for cracks or brittle insulation

Apply a thin layer of dielectric grease to the contact surfaces after cleaning (this prevents future oxidation)

Ensure all washers and spacers are in their original positions — they help distribute pressure evenly

Verify that the connection point on the starter-generator is clean and undamaged

Proper preparation here directly affects the longevity of the repair.

Installation and Proper Torque Procedure

Reconnecting everything correctly prevents repeat failures:

Position the positive cable lug onto the starter-generator stud

Install washers and spacers exactly as they were originally

Thread the securing nut on by hand first to avoid cross-threading

Using a torque wrench, tighten the main connection nut to the manufacturer-specified value (this is extremely important — under-tightening causes resistance, while over-tightening can damage threads or crack components)

Double-check that no tools were left in the engine bay

Reconnect the battery — positive terminal first, then negative

Secure all removed trim pieces and engine covers

Post-Installation Checks and Verification

After completing the work, perform these final tests:

Start the engine and listen for normal cranking behavior

Observe the instrument cluster for any warning lights

Cycle the start-stop system several times to confirm proper operation

Check for smooth charging voltage at idle (typically around 14–15 volts)

Inspect the connection after a short drive for any signs of heat or looseness

Clear any stored fault codes using suitable diagnostic equipment if necessary

These checks confirm the repair was successful and the system operates as designed.

Common Mistakes to Avoid

Even experienced technicians can make these errors:

Forgetting to disconnect the battery before starting work

Using incorrect torque values (too loose or too tight)

Reusing a damaged positive cable without replacement

Not cleaning contact surfaces adequately

Cross-threading the main nut during reinstallation

Ignoring small washers or spacers during reassembly

Avoiding these pitfalls saves time and prevents comebacks.

Replacing the starter-generator connection on a BMW is a precise job that rewards careful attention. With proper technique, your vehicle's starting and charging systems will regain their reliable performance, ensuring smooth daily driving and efficient mild-hybrid operation.

More from BMW

How to fix DSC/ABS wheel speed sensor faults BMW

13.12.2025 13:46

How to replace run-flat tires and reset TPMS BMW

13.12.2025 13:40

How to fix electronic steering rack clunk BMW

13.12.2025 13:35

How to fix crankcase ventilation (PCV) valve heater BMW

13.12.2025 13:13

How to replace IBS battery sensor false errors BMW

13.12.2025 13:06