How to replace air suspension compressor BMW

Replacing the air suspension compressor on a BMW ranks among the most rewarding yet challenging DIY repairs. When the pump fails, you typically face sagging corners, the infamous "Chassis Function Restricted" warning, or a compressor that runs endlessly without building pressure. This guide provides detailed, real-world steps that go beyond basic instructions.

Why BMW Air Suspension Compressors Fail (and How to Spot It Early)

BMW air suspension systems rely on a small but powerful electric pump to maintain ride height. The most common death scenarios include:

Internal piston seizure from overheating

Burnt armature due to constant short-cycling

Moisture-damaged windings after repeated cold starts in wet conditions

Oil contamination from dying air springs entering the system

Early warning signs that almost always indicate the pump (not just a leak):

Compressor becomes scorching hot after 30–60 seconds of running

Distinctive acrid electrical burning smell near the rear

Compressor buzzes loudly instead of smooth humming

Rapid on-off cycling every few seconds

System raises very slowly even after long running time

Fuse blows repeatedly or relay makes chattering noise

Essential Tools and Small Parts You Should Prepare

You will need more than just sockets. The following list separates must-have items from strongly recommended ones:

Must-have tools:

Full metric socket set (8–17 mm)

Torx bits T25–T45

Long ratchet extensions (150–300 mm)

Plastic trim removal tools

Torque wrench (5–50 Nm range)

Jack stands + proper floor jack

Strongly recommended extras:

Small inspection mirror

Air line disconnection tool

Shop vacuum

Dielectric grease

Medium-strength threadlocker

New rubber mounting grommets (almost always included with quality reman units)

Model-Specific Access Locations

BMW engineers placed the compressor in different locations depending on generation:

E39 5-Series – under the left rear seat (easiest access)

E60/E61 5-Series – left side under rear seat or trunk floor

E65/E66 7-Series – under spare wheel well in trunk

E70 X5 – behind left rear wheel arch liner or under spare wheel

F01/F02 7-Series – right side of trunk behind trim panel

F15/F16 X5/X6 – left rear wheel arch liner (tight space)

G30 5-Series / G31 Touring – under rear seat cushion

Pro tip: on most sedans, removing the rear seat bottom cushion takes under 60 seconds and gives dramatically better working space.

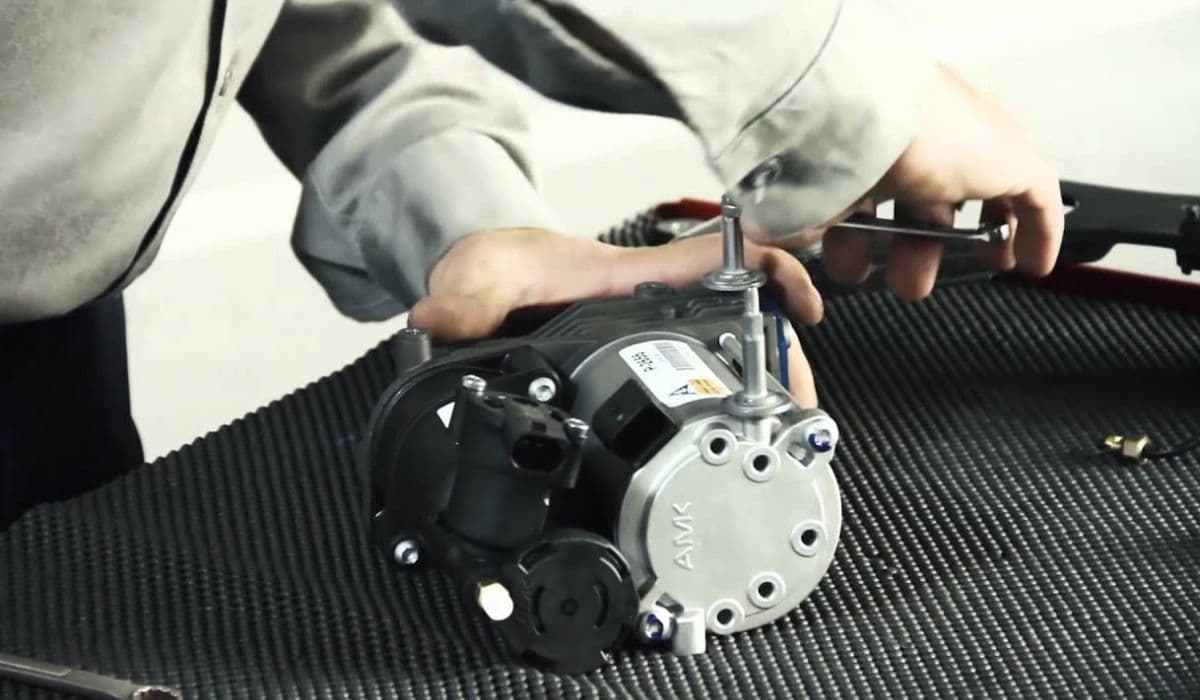

Step-by-Step Removal Process

Follow these steps in order for smooth disassembly:

Park on level concrete surface and let the car sit for at least 6–8 hours (fully depressurized system)

Disconnect negative battery terminal and wait 10 minutes

Mark ride height sensor arm positions with permanent marker or paint (extremely important!)

Remove necessary trim panels using plastic tools

Unplug electrical connector (note the locking tab direction)

Release air lines – one is supply, others go to valve block/reservoir (mark them!)

Support compressor body, remove three mounting bolts

Carefully maneuver the unit out – watch for pinched wiring harnesses

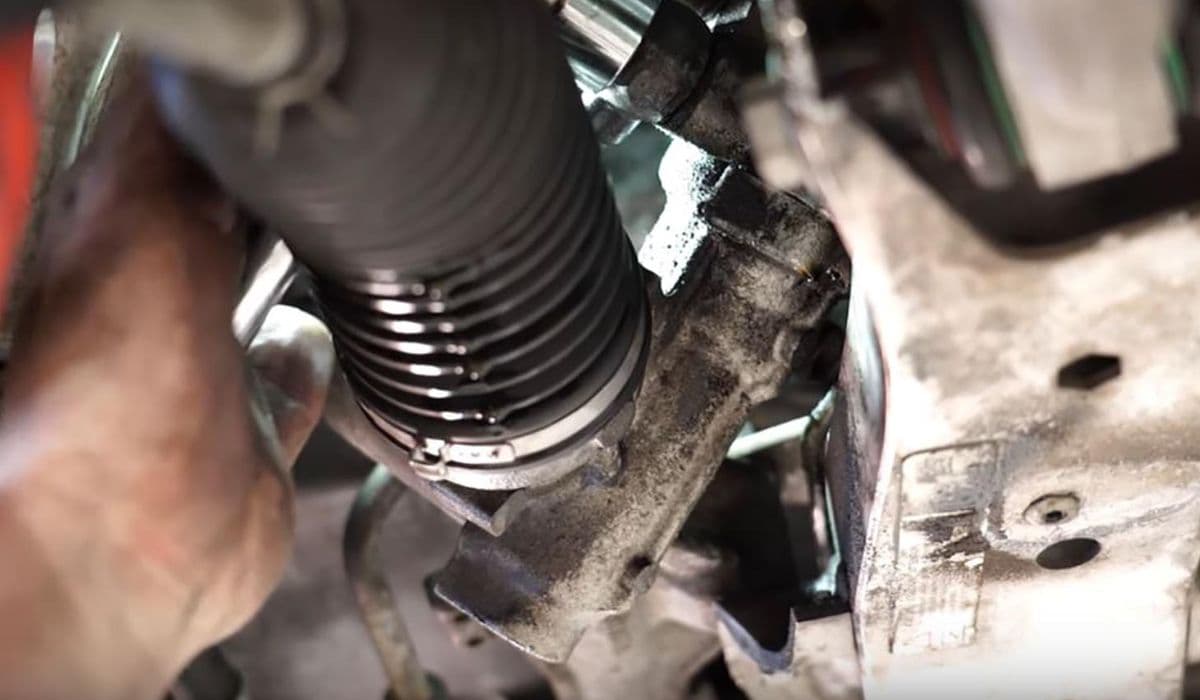

Critical Inspection Points Before Installing New Unit

While everything is apart, perform these quick checks:

Condition of air dryer (replace if dark brown or oily)

Airline condition – look for micro-cracks and brittleness

Valve block fittings – check for internal scoring

Relay socket – burnt contacts mean replace relay + socket

Main ground point – corrosion here kills many new compressors

Installation – The Right Way

The installation phase determines whether your new compressor will last 3 months or 10+ years:

Install fresh rubber mounts/grommets first (old ones always collapse)

Position unit, start all bolts by hand

Reconnect air lines in correct order (hand-tight only at this stage)

Apply thin layer of dielectric grease to electrical connector

Torque mounting bolts to factory specification (usually 10–22 Nm)

Secure wiring harness away from exhaust heat shields

Double-check all air connections before closing panels

Post-Installation Procedure and Initialization

Skipping this phase is the #1 reason for premature second failure:

Reconnect battery

Start engine (do NOT touch suspension controls yet)

Using compatible scanner, perform "Air Suspension Initialization" or "Ride Height Calibration"

Cycle suspension through 3–5 complete up/down movements

Monitor compressor current draw and temperature (live data)

Clear all fault codes and re-check after 50–100 km of driving

Most Common Post-Replacement Issues (and Fixes)

Even experienced owners encounter these situations:

Compressor runs but car stays low → reversed air lines or faulty valve block

Very slow raising → small leak (check corner air springs first)

"Air suspension deactivated" message persists → ride height sensors need full re-calibration

New compressor noisy → overtightened bolts or missing rubber mount

Runs 2–4 seconds then shuts off → major leak (usually torn air spring)

Longevity Tips for Your Freshly Installed Compressor

Want the replacement to outlive the car? Follow these practical habits:

Fix even tiny leaks immediately – one leaking corner kills compressors fast

Replace air dryer every 80–120k miles or every pump change

Keep wheel arch liners and underbody relatively clean

Never allow system to run bone-dry – this introduces massive contamination

Consider external pressure relief valve modification on high-mileage vehicles

A successful BMW air suspension compressor replacement combines mechanical skill with diagnostic understanding. When done properly, it restores factory ride quality and often becomes one of the most satisfying repairs you'll ever complete.

More from BMW

How to fix DSC/ABS wheel speed sensor faults BMW

13.12.2025 13:46

How to replace run-flat tires and reset TPMS BMW

13.12.2025 13:40

How to fix electronic steering rack clunk BMW

13.12.2025 13:35

How to fix crankcase ventilation (PCV) valve heater BMW

13.12.2025 13:13

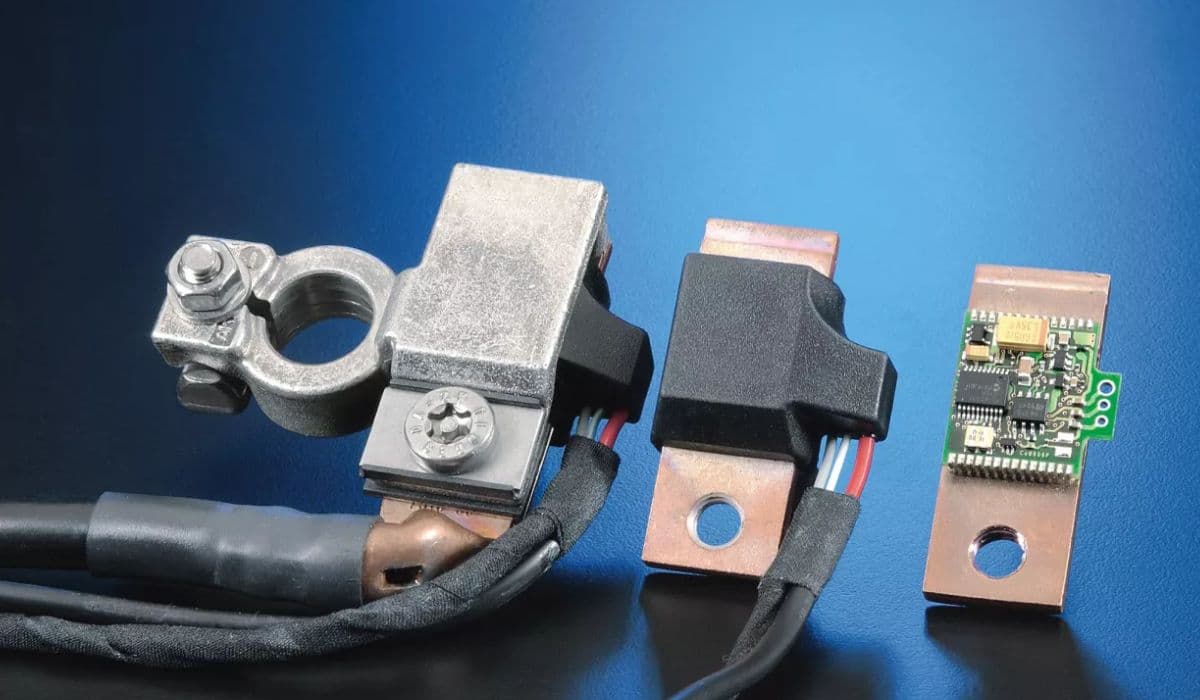

How to replace IBS battery sensor false errors BMW

13.12.2025 13:06