How to fix starter-generator loose connection BMW

Modern BMW vehicles, particularly those equipped with mild-hybrid technology, integrate a sophisticated starter-generator system that combines the functions of a traditional starter motor and alternator. This belt-driven or integrated unit, often operating on a 48V system, enhances fuel efficiency through features like seamless start-stop functionality and regenerative braking. However, one common issue that can disrupt this harmony is a loose electrical connection at the starter-generator, typically involving the positive battery cable or power connector. Such problems can lead to intermittent starting failures, unexpected engine stalls, or even warning lights on the dashboard, turning a smooth drive into a frustrating experience.

Understanding the Starter-Generator in BMW Models

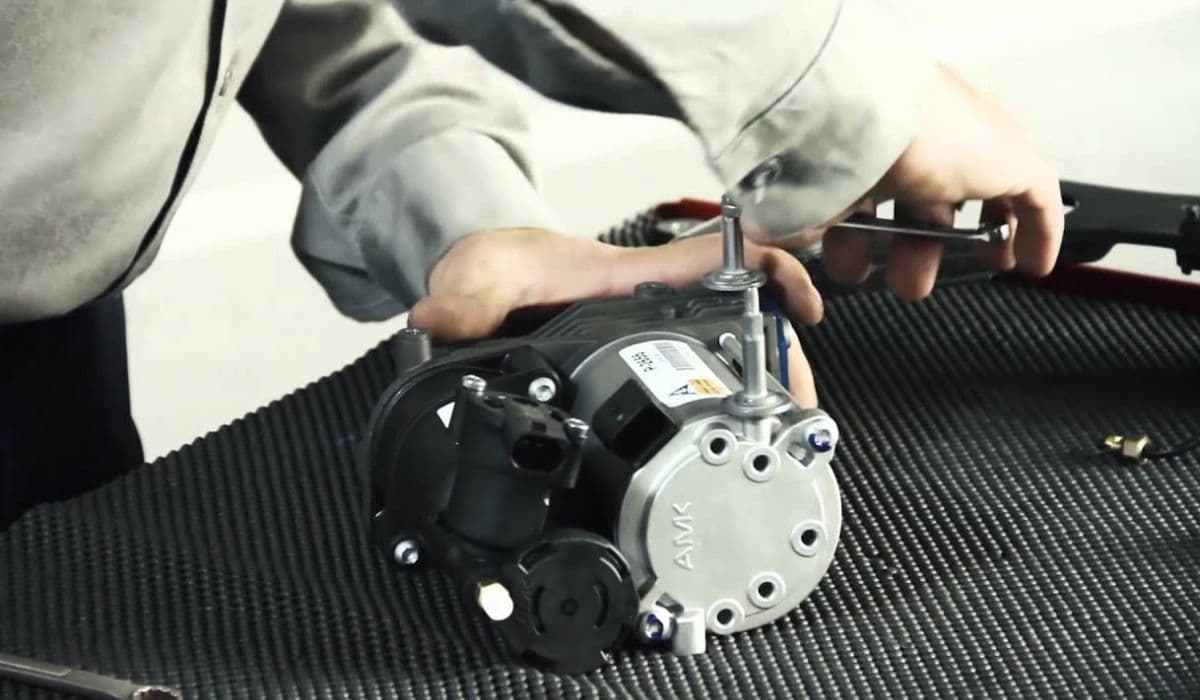

In many contemporary BMWs, the starter-generator replaces separate components for starting the engine and generating electricity. Mounted via a belt or directly integrated, it draws power from a dedicated battery setup to crank the engine quietly and efficiently while recovering energy during deceleration.

A loose connection often arises from manufacturing tolerances, vibration over time, or environmental factors like heat and moisture affecting the connector points. This can create increased electrical resistance, leading to heat buildup or power interruptions. Ignoring it might escalate from minor glitches to more serious drivability concerns, emphasizing the need for prompt attention.

Common Symptoms of a Loose Connection

Recognizing the signs early can prevent being stranded or facing larger repairs. Pay attention to these indicators:

Intermittent no-start conditions, where the engine cranks slowly or not at all despite a charged battery.

Unusual burning smells from the engine bay, hinting at overheating wires.

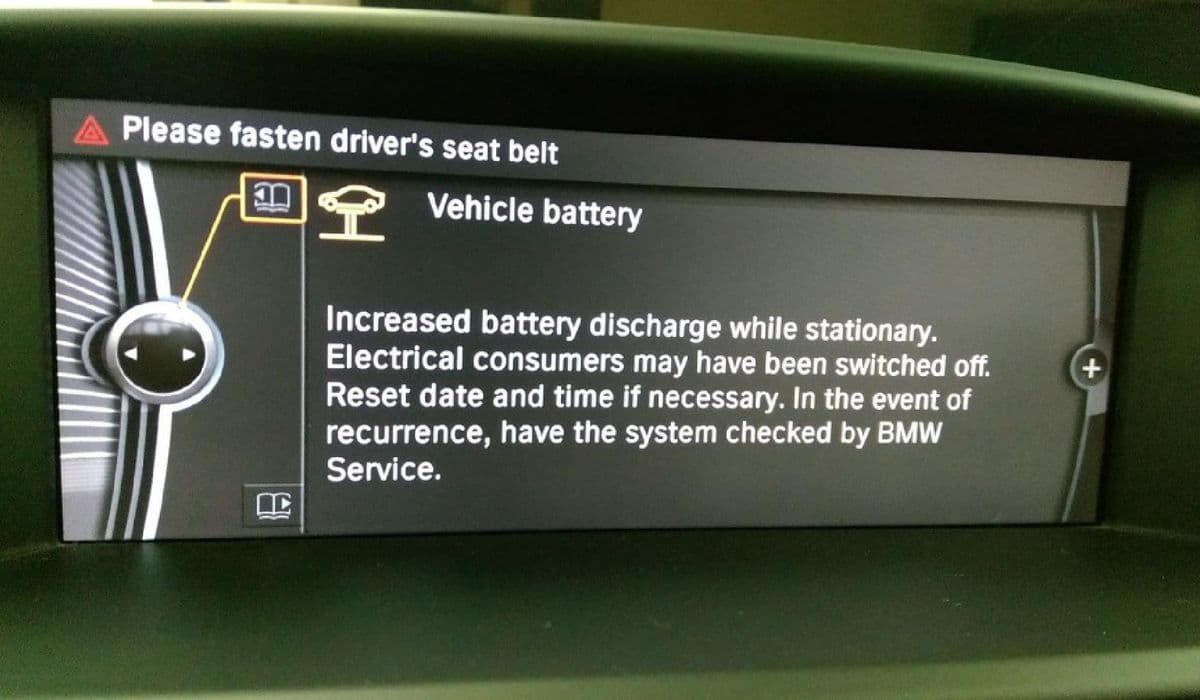

Dashboard warnings related to the charging system or hybrid functions.

Engine stalling during low-speed maneuvers or after coming to a stop.

Reduced performance in start-stop mode, with the system failing to restart smoothly.

Visible smoldering or discoloration around connection points upon inspection.

These symptoms stem from inconsistent power flow, disrupting the delicate balance of the electrical system.

Safety Precautions Before Any Repairs

Working on automotive electrical systems demands caution, especially with higher-voltage components in hybrid setups. Always prioritize safety to avoid shocks or damage:

Park the vehicle on a level surface and engage the parking brake.

Turn off the ignition and remove the key.

Disconnect the 12V battery negative terminal first to de-energize the system.

For 48V systems, locate and disconnect the dedicated battery or high-voltage isolator if accessible.

Wear insulated gloves and use tools with non-conductive handles.

Allow the engine to cool completely to prevent burns.

If you're unsure about any step, consulting a professional technician is the wisest choice, as mishandling can void warranties or cause further issues.

Tools and Materials Needed

Gathering the right equipment ensures a smooth process. Typical items include:

Socket set and torque wrench for precise tightening.

Multimeter for testing voltage and continuity.

Wire brush or terminal cleaner for removing corrosion.

Dielectric grease to protect connections from moisture.

Inspection mirror and flashlight for hard-to-reach areas.

BMW-specific diagnostic scanner for reading fault codes.

Having these on hand streamlines the diagnosis and repair.

Step-by-Step Diagnosis Process

Begin with a thorough check to confirm the loose connection is the culprit:

Scan for fault codes using an OBD-II tool or BMW diagnostic software to identify charging or starter-related errors.

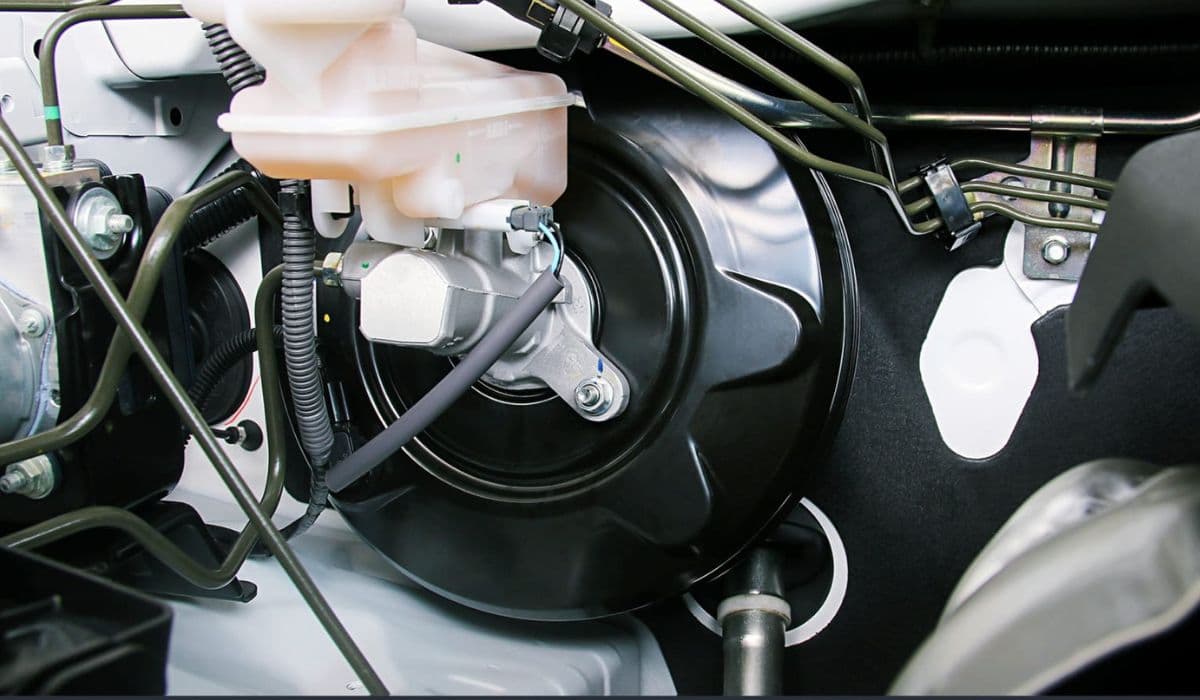

Visually inspect the starter-generator area, focusing on the positive cable attachment and connector.

Check for loose nuts, bolts, or harness clips.

Use a multimeter to measure voltage drop across the connection while attempting to start the engine.

Look for signs of corrosion, frayed wires, or heat damage.

This methodical approach pinpoints whether the issue is indeed a simple loose fitting or something deeper, like a faulty component.

Repairing the Loose Connection

Once diagnosed, addressing a loose connection can often restore full functionality:

Clean all contact surfaces thoroughly to remove dirt, oxidation, or residue that contributes to poor conductivity.

Tighten the connection bolts or nuts to the manufacturer's specified torque values, avoiding over-tightening which could strip threads.

Apply a thin layer of dielectric grease to seal against future corrosion.

Secure any loose wiring harnesses with zip ties or clips to minimize vibration.

Reconnect batteries in reverse order and clear any stored fault codes.

Test the system by starting the engine multiple times and monitoring for smooth operation.

In cases where the connector shows significant damage or a manufacturing gap, replacement of the cable or unit may be necessary, but tightening and cleaning often resolves vibration-induced looseness.

Preventive Maintenance Tips

Keeping the starter-generator connections reliable involves regular care:

Periodically inspect under the hood for signs of wear or looseness, especially after rough roads.

Ensure the battery terminals remain clean and tight.

Avoid short trips that strain the electrical system without full recharging cycles.

Monitor for software updates from BMW that might optimize hybrid functions.

Address any dashboard warnings immediately to catch issues early.

Consistent upkeep not only prevents loose connections but also maximizes the benefits of the mild-hybrid technology, like improved efficiency and quieter operation.

By understanding and tackling starter-generator loose connections proactively, BMW owners can maintain the renowned driving pleasure and reliability these vehicles offer, ensuring every journey starts and ends without unnecessary interruptions.

More from BMW

How to fix high-voltage battery shutdown (BMW i4/iX recall)

14.12.2025 14:38

How to replace starter-generator connection BMW

14.12.2025 11:51

How to fix panoramic roof noise or leaks BMW

14.12.2025 07:56

How to fix brake booster vacuum issues BMW

14.12.2025 06:06

How to replace 12V battery and register it (2025 BMW X5/iX issues)

14.12.2025 03:36