How to fix mysterious coolant loss (BMW B58/N55 engines)

BMW's B58 and N55 engines are engineering marvels, delivering thrilling performance with turbocharged efficiency. Yet many owners encounter a frustrating issue: gradual coolant disappearance without obvious puddles or drips under the car. This "mysterious" loss can stem from subtle leaks that evaporate on hot surfaces, trapped air, or component degradation in the complex cooling system. Addressing it early prevents overheating and potential engine damage.

Understanding the Cooling System in B58 and N55 Engines

These inline-six turbo engines feature sophisticated cooling setups to manage intense heat from combustion and forced induction. The N55, introduced earlier, uses a single coolant circuit, while the B58 often incorporates a dual-system design with a separate low-temperature loop for the charge air cooler. Coolant circulates through the block, head, turbocharger, and radiators via an electric water pump.

Pressurized to around 20-22 psi when hot, the system relies on plastic components, rubber seals, and precise fittings. Over time, thermal cycling causes brittleness in plastics, leading to micro-cracks or seal failures. Evaporation on exhaust manifolds or the turbo hides evidence, making leaks hard to spot visually.

Common Symptoms of Coolant Loss

Spotting the problem early is key to avoiding escalation.

Frequent low coolant warnings on the dashboard, even after topping up.

Slight sweet smell from the engine bay, indicating evaporating coolant.

White or chalky residue around hoses, fittings, or the oil filter housing.

Overheating during hard driving or idling in traffic.

Reduced air conditioning performance (especially on B58 with separate intercooler circuit).

Minor performance dips due to higher intake temperatures.

If ignored, persistent loss risks warped heads or seized components.

Frequent Causes of Mysterious Coolant Loss

Several culprits plague these engines, often without dramatic leaks.

Expansion Tank Cap Failure: The pressure relief cap on the reservoir often fails to seal properly, allowing slow vapor escape under heat.

Plastic Coolant Hoses and Connectors: Brittle vent lines or quick-connect fittings behind the oil filter housing crack, seeping when pressurized.

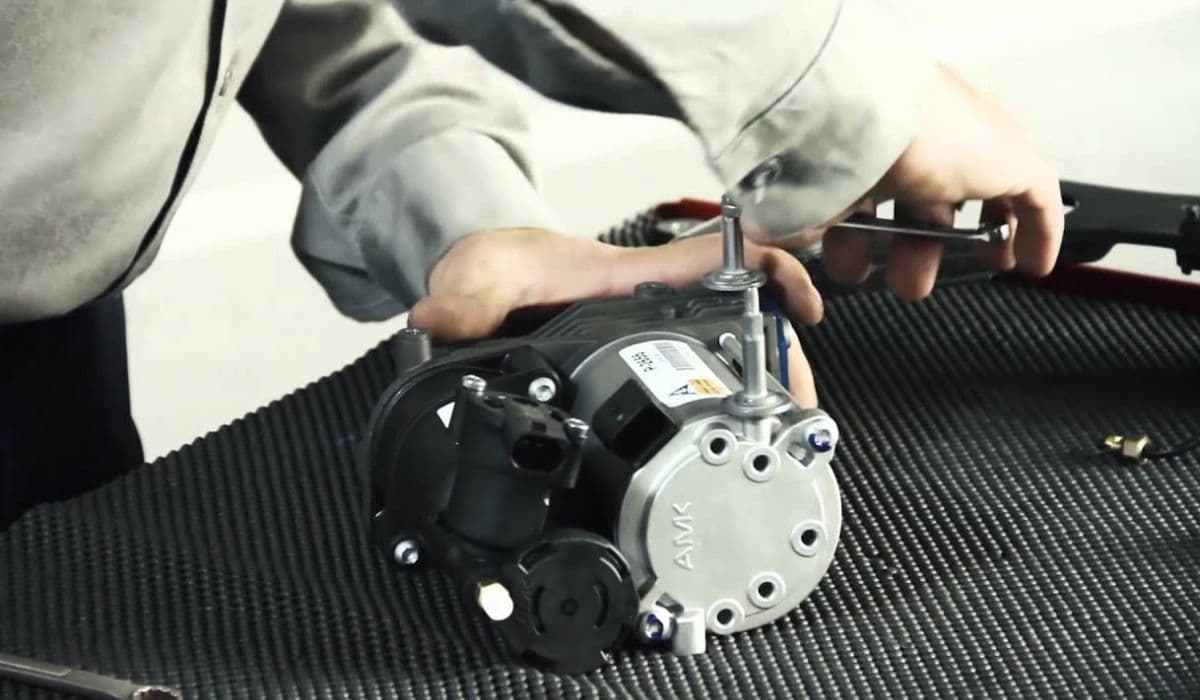

Water Pump Issues: Electric pumps develop seal leaks at the weep hole, or internal bearing wear reduces flow, mimicking loss.

Oil Filter Housing Area: Proximity to hot oil accelerates gasket or integrated coolant passage degradation.

Turbo Coolant Lines: Small lines to the turbocharger use plastic ends prone to cracking.

Trapped Air Pockets: Improper bleeding after service creates voids that displace coolant, triggering low-level alerts.

Radiator or Hose Micro-Leaks: Tiny pinholes evaporate fluid instantly on hot surfaces.

Rarely, head gasket issues arise, but these usually show cross-contamination signs like milky oil.

Step-by-Step Diagnostic Process

Diagnosing requires systematic checks, starting simple.

Inspect the engine bay with a flashlight for crystalline residue around common spots: water pump base, turbo lines, oil filter housing, and reservoir cap.

Check both reservoirs (main and low-temp on B58) cold; levels should sit between min/max marks.

Monitor usage over weeks, noting mileage and top-up amounts.

Perform a pressure test: Use a cooling system tester to pressurize to spec (around 20-30 psi cold). Hold for 15-30 minutes, watching for drops. Listen for hisses or spray.

Run the engine to operating temperature with the cap off, observing bubbles (indicating air or combustion gases).

Clean residue areas, drive normally, then re-inspect for fresh signs.

Professional tools like UV dye or combustion leak testers help pinpoint elusive issues.

Effective Fixes and Repairs

Once identified, most fixes are straightforward for experienced DIYers or shops.

Replace the expansion tank cap first—often resolves gradual loss.

Inspect and swap brittle plastic hoses, especially vent lines near the oil filter housing.

Renew the electric water pump if weeping or noisy; pair with thermostat for reliability.

Address oil filter housing leaks by resealing or upgrading components.

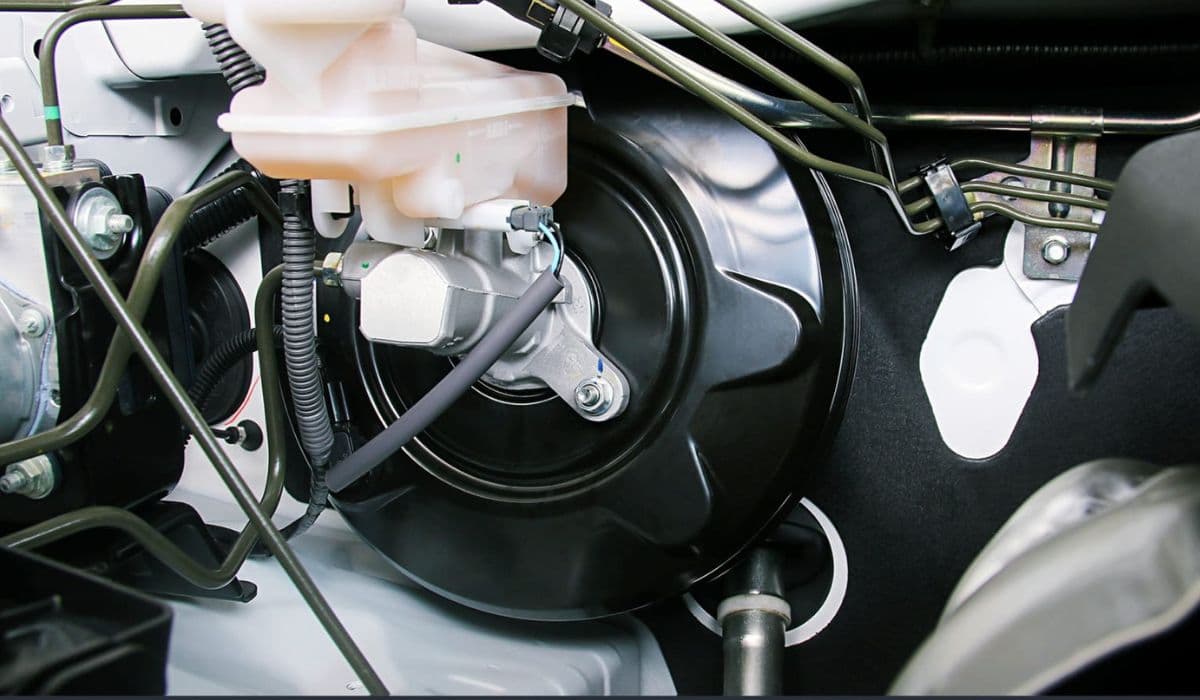

Thoroughly bleed the system: Use the electric pump cycle (ignition on, heat max, low fan) or vacuum filler for air removal.

Clean and inspect radiators for hidden damage; replace if needed.

After repairs, always pressure test and bleed properly to confirm integrity.

Prevention Tips for Long-Term Reliability

Proactive care keeps these engines trouble-free.

Use only BMW-spec coolant, mixed correctly with distilled water.

Check levels monthly and before long trips.

Avoid overfilling reservoirs to prevent pressure spikes.

Service the cooling system every few years, replacing wearable plastics preemptively.

Drive gently until fully warm to minimize thermal shock.

Monitor for early warnings via OBD scans.

With attention, B58 and N55 engines deliver exceptional durability alongside their performance.

More from BMW

How to fix high-voltage battery shutdown (BMW i4/iX recall)

14.12.2025 14:38

How to replace starter-generator connection BMW

14.12.2025 11:51

How to fix panoramic roof noise or leaks BMW

14.12.2025 07:56

How to fix brake booster vacuum issues BMW

14.12.2025 06:06

How to replace 12V battery and register it (2025 BMW X5/iX issues)

14.12.2025 03:36