How to fix transfer case failure (BMW X5 common 9K repair)

The BMW X5's xDrive system delivers exceptional all-wheel-drive performance, seamlessly distributing power between the front and rear axles for superior traction and handling. At the heart of this system lies the transfer case, a sophisticated component that manages torque split in real time. However, many X5 owners encounter transfer case issues over time, often manifesting as a noticeable problem around higher mileage. Understanding the causes, recognizing early warning signs, and knowing the repair options can help restore your vehicle's smooth operation and prevent further drivetrain damage.

Understanding the Transfer Case in BMW X5

In the BMW X5, the transfer case—often referred to as the Active Torque Control (ATC) unit in models like ATC400, ATC500, or ATC700 depending on the generation—works alongside the transmission to enable the xDrive all-wheel-drive functionality. It uses an electronically controlled clutch pack to vary torque distribution, typically favoring the rear wheels for a sportier feel while engaging the front as needed for grip.

This design excels in dynamic driving conditions, but the constant engagement and disengagement of the clutch, combined with internal components like chains, gears, and the actuator motor, can lead to wear. The system's sensitivity to factors like tire differences amplifies stress, making proactive maintenance essential for longevity.

Common Symptoms of Transfer Case Failure

Spotting transfer case problems early can save significant hassle. BMW X5 owners frequently report distinct signs that point to this component rather than the transmission or differentials.

Jerking or shuddering during acceleration, especially at low speeds or when turning

Binding sensation in tight maneuvers, like parking lot turns

Unusual grinding, whining, or clunking noises from underneath the vehicle

Warning lights for xDrive, AWD, or drivetrain malfunctions on the dashboard

Hesitation or vibration when shifting gears or applying throttle

Fluid leaks around the transfer case area

These symptoms often worsen in stop-and-go traffic or when the system detects wheel speed differences, forcing it into protective modes.

Main Causes of Transfer Case Issues in BMW X5

Transfer case failures in the X5 rarely happen overnight; they stem from cumulative stress on internal parts.

One prevalent issue involves the actuator motor and its associated gears. The actuator controls clutch engagement, and over time, plastic gears inside can strip or wear, preventing proper torque distribution.

Another common culprit is chain stretch within the transfer case. The drive chain linking input and output shafts can elongate, causing slippage and noise.

Clutch pack wear from repeated cycling, degraded fluid losing its lubricating properties, and mismatched tires creating constant compensation demands also accelerate problems. Even minor differences in tire circumference force the system to work harder, leading to premature component fatigue.

Diagnosing Transfer Case Problems

Accurate diagnosis requires a systematic approach, ideally with BMW-specific tools.

Start with a visual inspection for leaks and check tire conditions—ensure all four match in brand, size, and tread depth.

Scan for fault codes using a compatible OBD tool; common codes relate to actuator position or xDrive malfunctions.

Test drive to replicate symptoms, noting when shuddering occurs. Some technicians measure chain stretch by accessing internal components or use software to monitor torque split.

In certain cases, a fluid change and system recalibration resolve early issues, confirming if the problem is lubrication-related rather than mechanical damage.

Repair Options for BMW X5 Transfer Case Failure

Fixing a failing transfer case varies from simple maintenance to major overhaul, depending on the root cause.

For actuator-related faults, repairing or replacing the actuator motor often suffices. This involves removing the unit, inspecting gears, and either rebuilding with reinforced parts or installing a new assembly.

Chain stretch typically requires splitting the case to replace the chain, a more involved process that may include new bearings and seals for reliability.

In advanced wear scenarios, full transfer case replacement—using a remanufactured or new unit—becomes necessary. This ensures all components are refreshed.

Fluid service is a key step in any repair: drain old fluid, replace with the correct specification, and recalibrate the system via diagnostic software.

Some owners opt for preventive upgrades, like stronger aftermarket chains or regular fluid intervals, to extend life.

Preventing Future Transfer Case Problems

Maintaining your X5's transfer case proactively keeps the xDrive system performing at its best.

Rotate tires regularly and replace them in matched sets to avoid speed differentials

Adhere to fluid change intervals using BMW-approved oil

Avoid aggressive low-speed maneuvers on dry pavement when possible

Monitor for early vibrations and address them promptly

Use diagnostic tools periodically to check for pending codes

These habits reduce stress on the clutches and chains, preserving the intricate balance that makes xDrive so effective.

By addressing transfer case issues methodically—through early detection, precise diagnosis, and appropriate repairs—BMW X5 owners can regain the confident, responsive handling that defines the model. The system's engineering brilliance shines when properly cared for, turning a common concern into a manageable aspect of ownership.

More from BMW

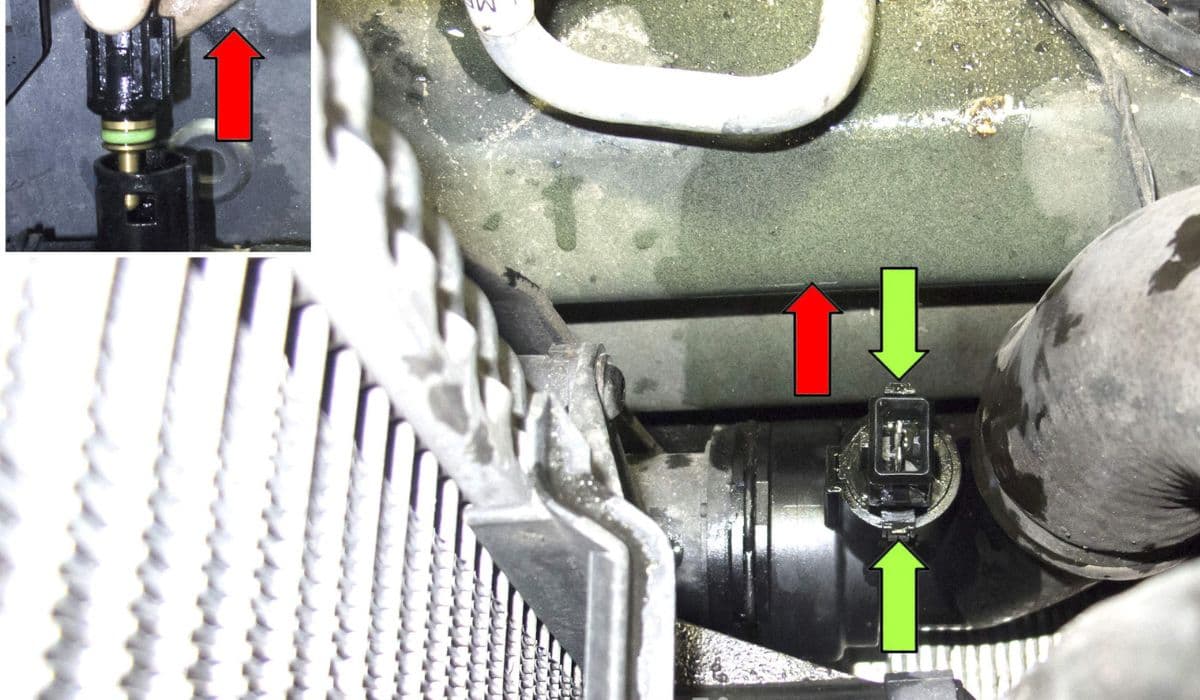

How to replace brittle plastic radiator sensor BMW

20.12.2025 09:10

How to fix dash delamination from weak glue BMW

20.12.2025 09:09

How to fix coil whine in drivetrain (BMW new models)

20.12.2025 06:41

How to fix mysterious coolant loss (BMW B58/N55 engines)

19.12.2025 22:06

How to replace integrated PCV valve in valve cover BMW

19.12.2025 19:56