How to replace battery BMW cable safety terminal

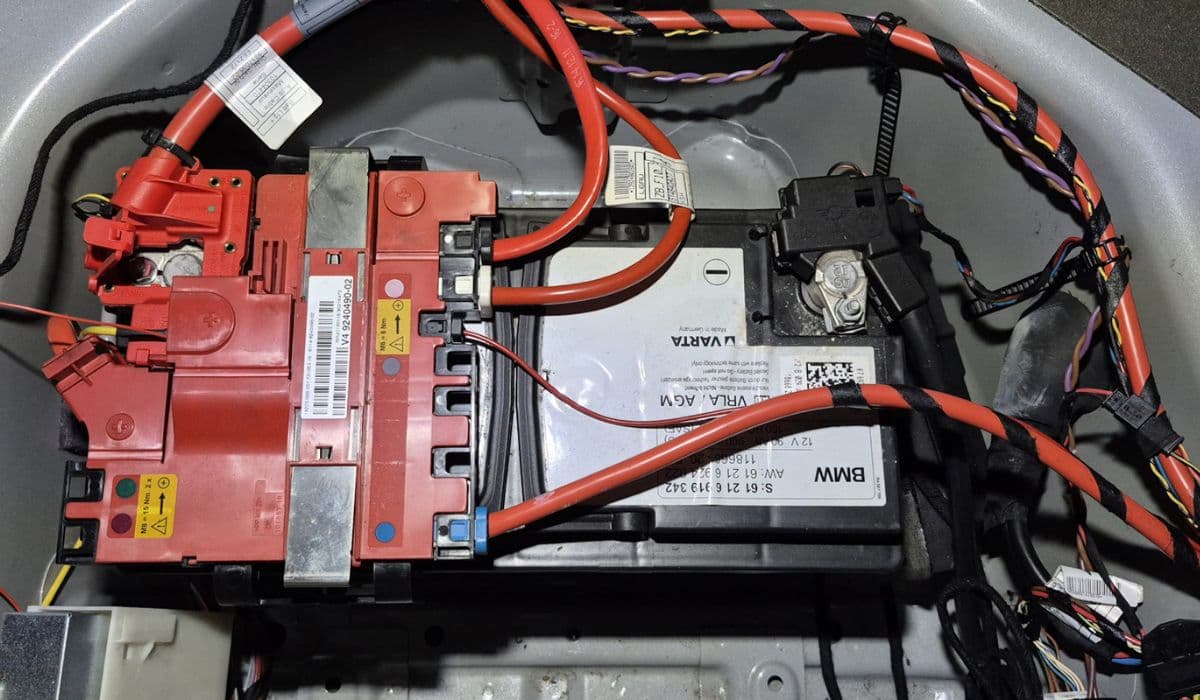

The Battery Safety Terminal (BST), also known as the pyrotechnic safety switch, is a clever engineering feature in many BMW models. This device sits on the positive battery cable and is designed to protect the vehicle and its occupants during a severe collision. Triggered by the airbag control module, it uses a small explosive charge to sever the connection between the battery and the main power feed to the starter and alternator. This rapid disconnection helps prevent potential electrical fires caused by damaged wiring short-circuiting against the body. Interestingly, even after activation, essential systems like hazard lights, door locks, and central electronics remain powered through a separate fused circuit, allowing for emergency functions post-impact.

While the BST is a one-time-use component that enhances safety, it can sometimes activate unexpectedly due to minor impacts, electrical surges, or even wear over time. When it does, the car may refuse to start, or warning lights for the airbag system appear on the dashboard. Replacing it restores full functionality and maintains the vehicle's safety integrity.

Understanding the Battery Safety Terminal

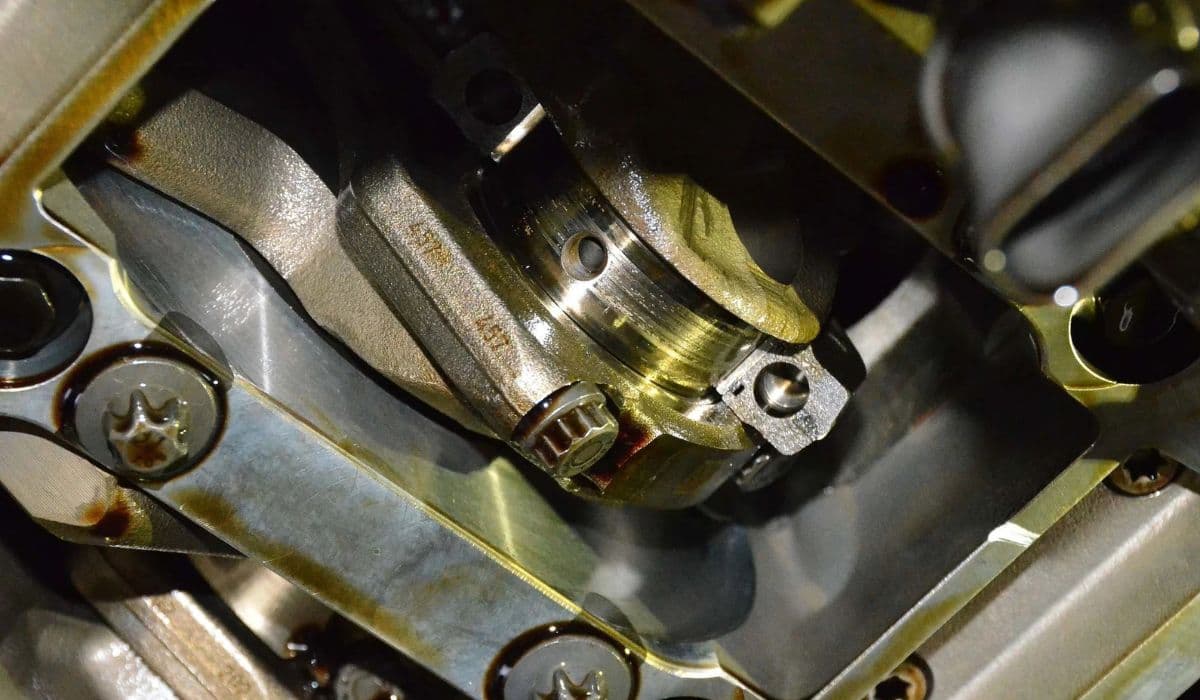

The BST integrates a sensor and pyrofuse into the positive battery cable clamp. In normal operation, it allows uninterrupted power flow. But in a crash detected by acceleration sensors, the module sends a signal, igniting the charge. This pushes a piston that physically breaks the conductor inside the terminal, isolating the high-current unfused line to the engine bay.

Reduces fire risk by disconnecting the battery from damaged high-power circuits.

Keeps auxiliary systems operational via a secondary cable routed to the rear distribution box.

Often located in the trunk on many BMWs, where the battery is housed for better weight distribution.

This system reflects BMW's focus on passive safety, blending electronics with mechanical failover for real-world protection.

Signs That Your BST Needs Replacement

Identifying a faulty or triggered BST early can prevent frustration with no-start conditions or persistent warning lights. Common indicators include:

The engine cranks but doesn't fire, or there's complete electrical silence despite a charged battery.

Airbag or SRS warning light illuminated, sometimes accompanied by restraint system faults.

Loose or displaced positive cable at the battery post, visible upon inspection.

History of front-end impact, even minor, that might have jolted the sensors.

Scanning with a compatible diagnostic tool often reveals specific codes related to the safety battery terminal resistance or firing circuit.

Tools and Materials Required

Performing this replacement is a manageable DIY task for those comfortable with basic automotive work. You'll need:

Basic hand tools: 10mm socket or wrench, flathead screwdriver, torque wrench.

Wire cutters and strippers if using a repair kit.

Diagnostic scanner capable of reading and clearing airbag module codes.

Replacement BST cable or repair kit matched to your model.

Protective gloves and eye wear for safety.

Working in a well-ventilated area and ensuring the ignition is off adds peace of mind.

Safety Precautions Before Starting

Battery work always demands caution, especially with integrated safety systems.

Park on a flat surface, engage the parking brake, and remove keys from the ignition.

Allow the vehicle to sit for at least 10-15 minutes to discharge any residual capacitor power in the airbag system.

Wear insulated gloves to avoid shocks.

Avoid smoking or open flames near the battery.

If the airbags have deployed recently, consider professional assistance due to potential hazards.

Proper precautions make the process smooth and risk-free.

Step-by-Step Replacement Guide

The procedure varies slightly by model, but the core steps remain consistent. Most BMWs place the battery in the trunk.

First, access the battery compartment by opening the trunk and removing any covers or retainers on the right side.

Disconnect the negative terminal first using a 10mm wrench to prevent sparks.

Then loosen the positive terminal, noting any accessory wires attached.

Unplug the small connector with two wires leading to the BST sensor—these link to the airbag system.

Carefully pry off the plastic cover over the BST housing with a flathead screwdriver.

Remove the old terminal assembly; if triggered, you may see signs of the internal separation.

For full cable replacement:

Trace the positive cable routing and prepare the new one.

Align the replacement alongside the old, mark the cut point for splicing if using a kit.

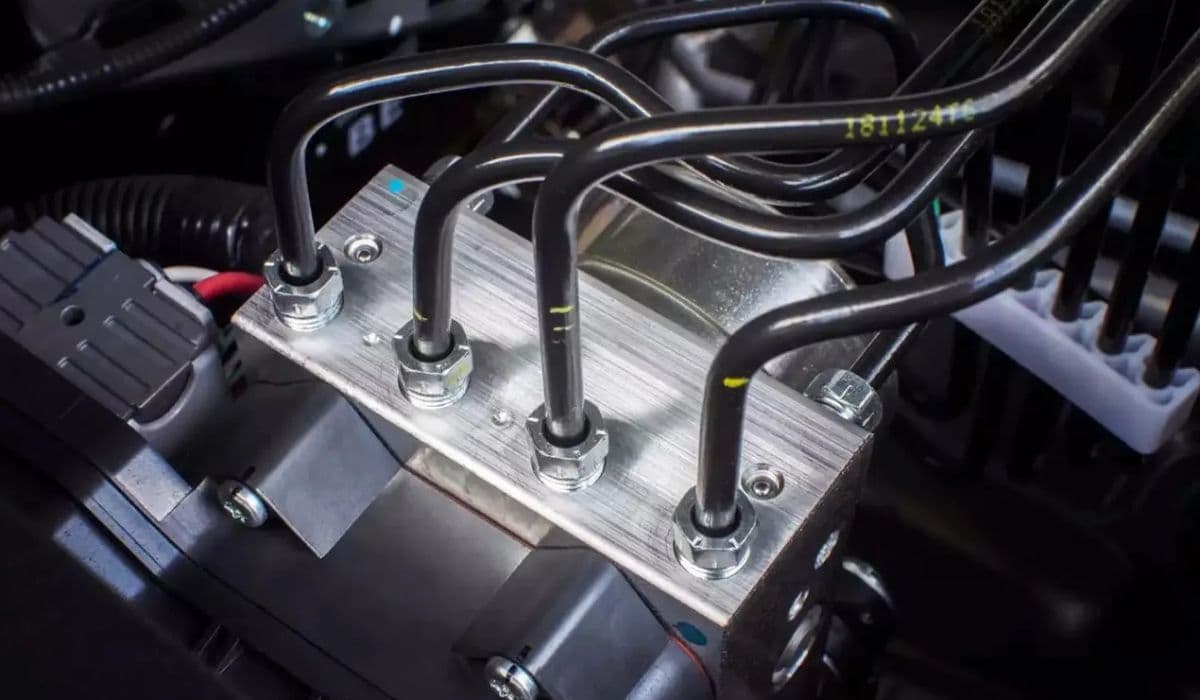

Cut the cable cleanly, strip ends, and secure with the provided connector or crimp.

For terminal-only swap:

Install the new clamp directly onto the battery post.

Reconnect the sensor wires firmly.

Torque connections to specifications for reliable contact.

Finally:

Reattach the positive terminal, followed by the negative.

Secure all covers and trim.

The key is methodical handling to avoid damaging surrounding components.

Clearing Fault Codes After Installation

A triggered BST often stores permanent faults in the airbag module, requiring clearance.

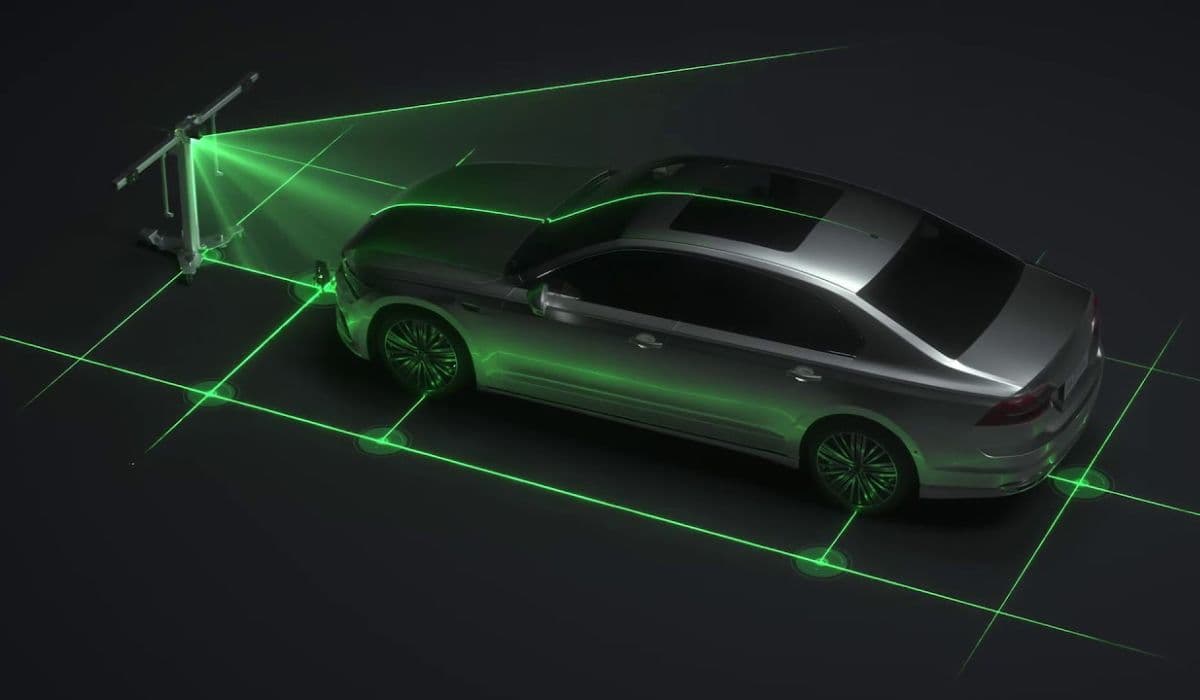

Connect a scanner that supports BMW SRS systems.

Read existing codes to confirm BST-related issues.

Clear the faults; the system should recognize the new component.

Cycle the ignition and verify no warnings return.

If codes persist, double-check connections or sensor wiring integrity.

Testing the New Installation

Once complete, thorough testing ensures everything functions correctly.

Start the engine and monitor for smooth operation.

Check dashboard for cleared warnings.

Test electrical accessories: lights, windows, radio.

Drive briefly and scan again if needed.

A successful replacement brings the car back to full reliability, preserving that signature BMW driving experience.

Maintenance Tips to Prolong BST Life

While the BST is robust, proactive care minimizes premature issues.

Regularly inspect battery terminals for corrosion and clean as needed.

Secure cables to prevent chafing or vibration damage.

Address minor impacts promptly with diagnostics.

Use quality batteries that match OEM specs for stable voltage.

These habits keep the electrical system healthy and the safety features ready when needed.

More from BMW

How to fix ABS module BMW faults

20.12.2025 17:59

BMW: How to replace coolant hoses and expansion tank

20.12.2025 11:51

How to fix rod knock in tuned BMW S55 engines

20.12.2025 11:41

How to replace high-pressure fuel pump BMW(HPFP)

20.12.2025 11:38

How to fix ADAS camera BMW calibration after windshield

20.12.2025 11:02