How to replace rod bearings preemptively BMW (G80 M3)

The BMW G80 M3, powered by the high-revving S58 inline-six engine, represents the pinnacle of performance engineering. However, like many high-output turbocharged engines, it faces potential issues with rod bearings over time. Preemptive replacement of these components can prevent catastrophic failure, ensuring longevity and reliability. This guide delves into the process, offering detailed insights for enthusiasts and mechanics tackling this task on the G80 M3.

Understanding Rod Bearings in the G80 M3 Engine

Rod bearings, also known as connecting rod bearings, are critical components in the crankshaft assembly of the S58 engine found in the G80 M3. These bearings sit between the connecting rods and the crankshaft journals, providing a low-friction surface that allows smooth rotation under extreme loads. In the G80 M3, the S58 produces up to 503 horsepower and 479 lb-ft of torque, putting immense stress on these parts.

The bearings are typically made from a tri-metal construction: a steel backing, an aluminum or copper-lead intermediate layer, and a soft overlay for embeddability. Over time, factors like oil starvation, excessive heat, or manufacturing tolerances can lead to wear. In the S58, early production models (2021-2022) have been noted for accelerated bearing degradation due to potential inconsistencies in oil pressure delivery and material composition. BMW has acknowledged this through technical service bulletins (TSBs), recommending inspections at certain mileage intervals.

Preemptive replacement involves swapping out the bearings before visible damage occurs, often around 30,000 to 50,000 miles, depending on driving habits. This approach is particularly relevant for track enthusiasts or those with tuned engines, where rev limits and boost levels exacerbate wear. Symptoms of failing bearings include unusual knocking sounds, reduced oil pressure, or metal shavings in the oil filter—though by then, it's often too late for prevention.

Why Preemptive Replacement Matters for G80 M3 Owners

Opting for preemptive rod bearing replacement in your G80 M3 isn't just about avoiding downtime; it's a strategic move to safeguard your investment. The S58 engine's design, while robust, inherits some vulnerabilities from its B58 predecessor, amplified by higher power outputs. Historical data from BMW forums and independent shops shows that untreated bearing wear can lead to spun bearings, where the component seizes and damages the crankshaft, necessitating a full engine rebuild costing upwards of $20,000.

By replacing bearings early, you mitigate risks associated with high-mileage operation. For instance, aggressive driving on circuits like the Nürburgring can accelerate wear due to sustained high RPMs and lateral forces. Additionally, using subpar oil or skipping regular changes exacerbates the issue—BMW specifies 0W-30 full synthetic oil meeting LL-01 standards, but many owners upgrade to 5W-40 for better shear stability.

This procedure also allows for inspection of related components, such as the oil pump, VANOS system, and crankshaft itself. If you're modifying your G80 M3 with aftermarket tunes or exhaust systems, preemptive work ensures the bottom end can handle increased stress. Statistically, vehicles with proactive maintenance see a 30-50% extension in engine life, based on reports from M3-specific communities like M3Post and Bimmerpost.

Essential Tools and Materials for the Job

Before diving into the replacement, gather the right tools and materials to ensure a smooth process. This isn't a beginner's task; it requires intermediate to advanced mechanical skills and a well-equipped garage.

Key tools include:

A high-quality engine hoist and stand, as the engine must be removed for access.

Torque wrenches calibrated for both inch-pounds and foot-pounds (essential for precise bearing cap torquing).

Plastigage for measuring bearing clearances.

Micrometers and dial indicators for checking crankshaft journals.

A harmonic balancer puller and installer.

Specialty BMW tools like the VANOS locking tool (part number 83 30 2 468 664) and camshaft alignment tools.

Socket sets, including deep-well sockets for rod cap bolts.

Materials needed:

OEM or upgraded rod bearings (BMW part 11 24 8 684 064 for standard, or aftermarket options like ACL Race Series for enhanced durability).

New rod bolts (always replace these, as they are torque-to-yield).

Engine gasket set, including head gasket if you're going deeper.

High-temperature assembly lube (e.g., ARP Ultra-Torque).

Fresh engine oil (10 quarts of BMW-approved 0W-30) and a new oil filter.

Coolant and other fluids for refilling.

Budget for $1,500 to $3,000 in parts alone, excluding labor if you're outsourcing. Sourcing from reputable suppliers like ECS Tuning or FCP Euro ensures authenticity. Always verify compatibility with your specific VIN, as G80 M3 variants (Competition vs. base) may have slight differences.

Preparing Your G80 M3 for Rod Bearing Replacement

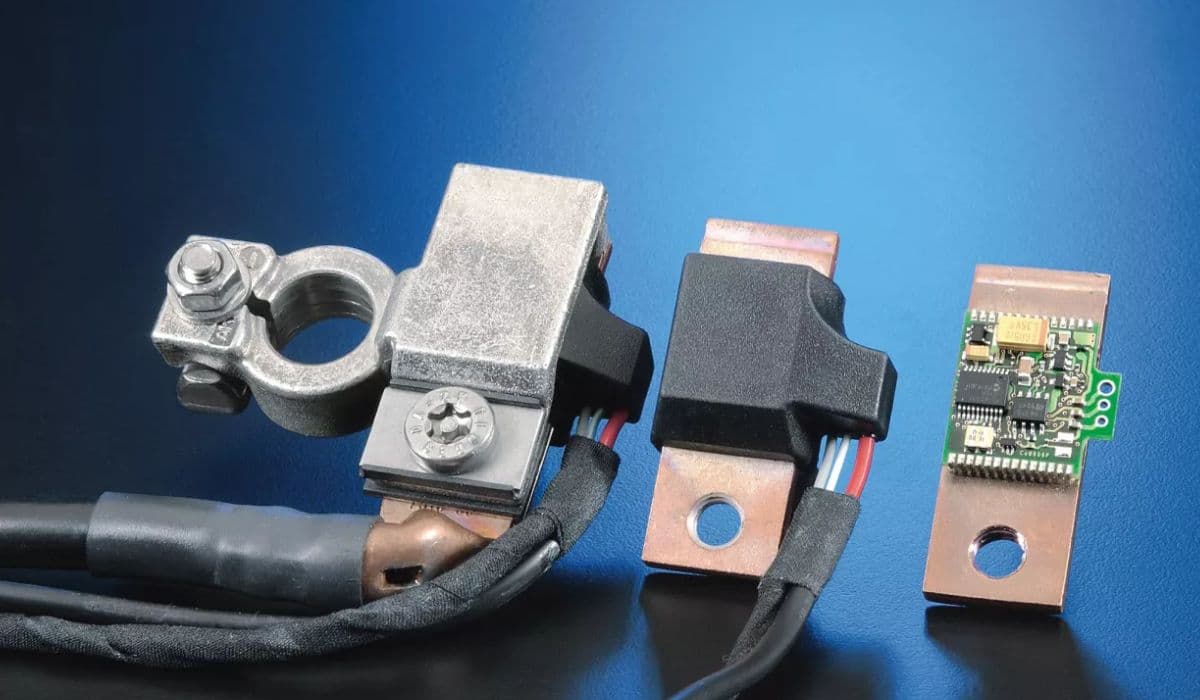

Preparation is key to a successful preemptive replacement. Start by parking the vehicle on a level surface and disconnecting the battery to prevent electrical issues. Drain the coolant and engine oil completely—use a fumeless drain pan for safety.

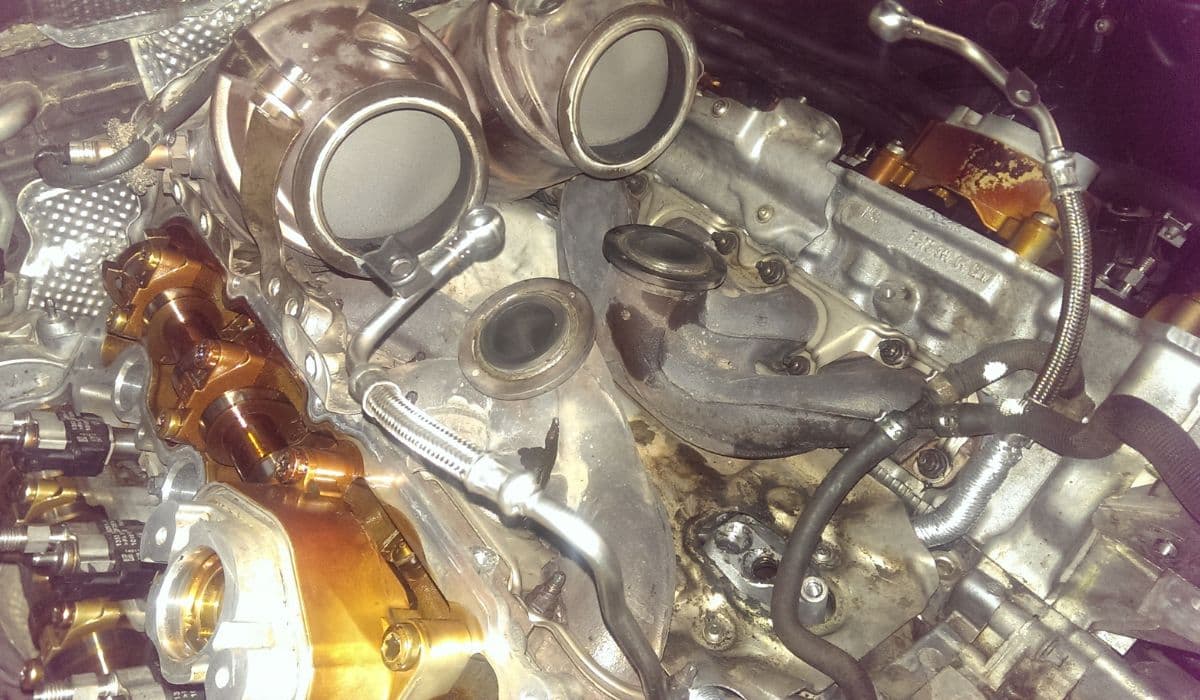

Remove ancillary components: Begin with the intake manifold, turbochargers, and exhaust manifolds. The S58's twin-turbo setup requires careful handling; label all hoses and connectors. Disconnect the wiring harness, fuel lines, and transmission (whether manual or ZF 8-speed automatic). Support the transmission with a jack before unbolting the engine mounts.

Hoist the engine out using secure lifting points on the block. Place it on an engine stand, rotating it upside down for bottom-end access. Clean the exterior thoroughly to prevent contaminants from entering during disassembly. Inspect the oil pan for debris; any metal particles could indicate pre-existing wear.

This stage also offers a chance to upgrade peripherals, like installing a baffled oil pan to combat starvation during hard cornering—a common mod for G80 M3 track cars.

Step-by-Step Guide to Replacing Rod Bearings

With the engine on the stand, proceed methodically.

Remove the Oil Pan and Pump: Unbolt the oil pan (22 bolts) and inspect the pickup tube. Remove the oil pump chain and sprocket if needed.

Access the Crankshaft: Rotate the engine to position each rod for access. Mark the rod caps and mains for reassembly orientation.

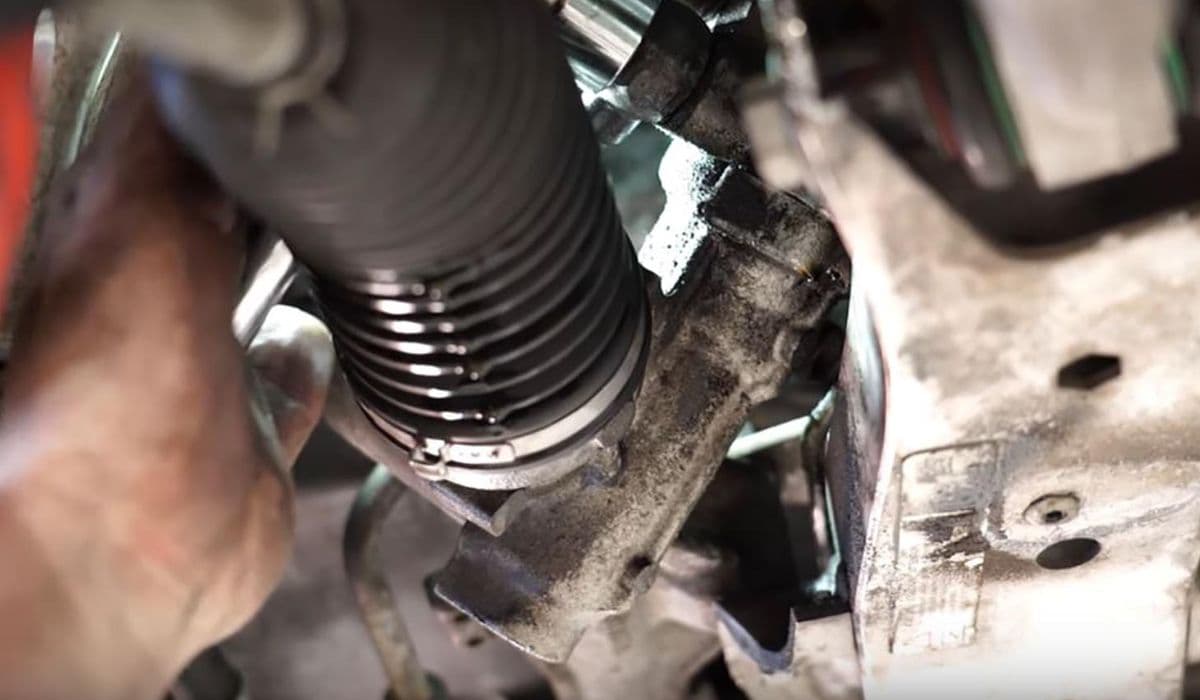

Remove Rod Caps: Loosen the rod bolts in a crisscross pattern to avoid warping. Gently tap the caps free. Note the bearing shell orientation—upper and lower halves are not interchangeable.

Inspect and Measure: Clean the journals and measure with a micrometer. Ideal clearance for S58 bearings is 0.0015-0.0025 inches. Use Plastigage to verify: Place a strip on the journal, torque the cap to spec (initial 15 ft-lb, then 90 degrees), and measure the crushed width.

Install New Bearings: Apply assembly lube to the new bearings. Insert them into the rods and caps, ensuring the tangs align. Reinstall caps with new bolts, torquing in stages: 15 ft-lb, then 30 ft-lb, followed by a 90-degree turn.

Reassemble Bottom End: Replace the oil pump if worn, and reinstall the pan with fresh sealant.

Reinstall Engine: Lower the engine back into the bay, reconnecting all components. Torque engine mounts to 52 ft-lb.

Break-In Procedure: Fill with oil and coolant. Start the engine, monitoring for leaks. Perform a gentle break-in: Idle for 20 minutes, then vary RPMs below 4,000 for the first 500 miles.

Throughout, maintain cleanliness—use lint-free cloths and avoid touching bearing surfaces with bare hands.

Common Challenges During G80 M3 Rod Bearing Work

Even experienced mechanics encounter hurdles. One frequent issue is seized bolts due to corrosion; apply penetrating oil overnight. Misalignment during reassembly can cause binding—always double-check rod orientation.

VANOS timing can shift if not locked properly, leading to check engine lights. Use the BMW-specific tools to realign cams. Over-torquing rod bolts risks stretching them beyond yield, so adhere strictly to specs.

For xDrive models, additional driveline disconnection adds complexity. If you're in a cold climate, warm the garage to prevent brittle gaskets.

Enhancing Durability Post-Replacement

After replacement, focus on maintenance to maximize benefits. Change oil every 5,000 miles with high-zinc formulas for better wear protection. Install an oil pressure gauge to monitor in real-time—drops below 20 psi at idle signal trouble.

Consider upgrades like a high-flow oil cooler or ECU remap for optimized oil delivery. Regular Blackstone oil analysis can detect early wear through metal content sampling.

Track your G80 M3 responsibly: Warm up the engine before pushing limits, and cool down after sessions. Joining BMW CCA chapters provides access to expert advice and group buys on parts.

Monitoring and Long-Term Care for S58 Engines

Ongoing vigilance is essential. Schedule dyno tests annually to check power output—dips could indicate issues. Use OBD-II scanners to monitor knock sensors, which often flag bearing problems indirectly.

Community resources like YouTube channels (e.g., M539 Restorations) offer visual aids, though hands-on experience is irreplaceable. If in doubt, consult certified BMW technicians familiar with M division engines.

By staying proactive, your G80 M3 can deliver thrilling performance for years, free from bearing-related woes.

More from BMW

How to fix DSC/ABS wheel speed sensor faults BMW

13.12.2025 13:46

How to replace run-flat tires and reset TPMS BMW

13.12.2025 13:40

How to fix electronic steering rack clunk BMW

13.12.2025 13:35

How to fix crankcase ventilation (PCV) valve heater BMW

13.12.2025 13:13

How to replace IBS battery sensor false errors BMW

13.12.2025 13:06