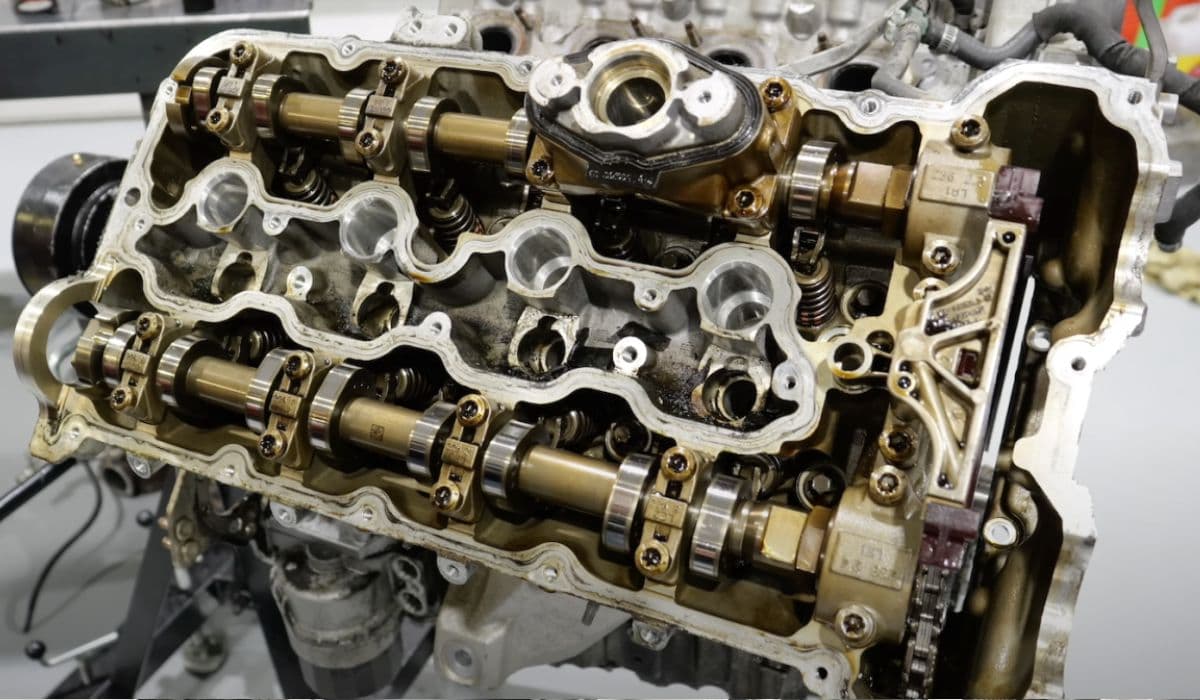

How to replace turbo oil lines (N63 hot-V engines)

BMW's N63 V8 twin-turbo engine, deployed in high-end models like the 550i, 650i, 750i, X5 xDrive50i, and X6 xDrive50i from 2008 to 2019, features a unique hot-V layout with turbos nestled between the cylinder banks for compact packaging and reduced lag. This design exposes turbo oil supply and return lines to extreme heat, accelerating degradation of seals, gaskets, and lines themselves. Oil return lines, routing from turbos to the valley pan cover, commonly develop leaks at connections due to thermal expansion, vibration, and age-related brittleness, typically surfacing around 80,000-120,000 miles.

The aluminum return cover gasket fails first, allowing oil to seep into the valley and evaporate on hot surfaces, while supply lines can crack under pressure spikes from tuned applications or neglected maintenance. Updated parts address early porous castings prone to seepage. Ignoring leaks risks oil starvation to turbos, leading to bearing failures, smoke, or complete turbo seizure—costs exceeding $5,000 per side. Interconnected coolant lines in the hot-V setup often leak concurrently, complicating diagnostics.

Spotting Early Manifestations of Oil Line Compromise

Subtle oil consumption without visible drips often evaporates, leaving faint blue smoke from the exhaust or a persistent burning odor in the cabin. Pooled oil in the engine valley, accessible via endoscope inspection, confirms return cover gasket breaches.

Dashboard low oil warnings trigger more frequently, while turbo whine or lag indicates restricted flow. Severe cases produce oil spray on underbody components or catalytic converters, risking fire hazards. Scanner codes may include low oil pressure faults or turbo efficiency deviations. Visual checks under the hood reveal wet spots around turbo housings or discolored heat shields from seepage.

Essential Toolkit and Component Sourcing Strategies

Major disassembly demands comprehensive preparation. Tools encompass E14/E16 external Torx sockets for manifolds, 10-18mm wrenches for lines, torque wrench (up to 200 Nm), gasket scrapers, and a borescope for valley inspection. Engine support bars or cranes hold the block during turbo removal, while coolant drain pans manage spills.

Genuine BMW parts ensure fit: Turbo oil supply lines (11427583221 left, 11427583222 right, ~$150 each), return lines with updated seals (11428637813 kit), and valley return cover gasket (11127587827). Aftermarket reinforced braided lines suit tuned engines. Include fresh turbo gaskets, manifold bolts (single-use stretch type), and high-temp sealant for covers.

Methodical Diagnostics to Isolate Leak Sources

Avoid blind replacement—endoscope the valley pan for oil accumulation distinguishing from valve cover leaks. Pressure test oil system to 5-7 bar, monitoring for drops around turbos.

Scan for pressure codes or misfires from contaminated sensors. Dye additive in oil fluoresces leaks under UV light. Differentiate coolant cross-contamination (milky oil) from pure seepage. If smoke persists without consumption, suspect turbo seals over lines.

Preparing the Engine Bay for Extensive Access

Cool the engine fully—hot-V turbos retain heat for hours. Drain coolant and oil via plugs, recovering for reuse if clean. Remove intake manifolds, charge pipes, and accessory belts for clearance.

Disconnect battery and relieve fuel pressure. Support the engine from above with a bar across mounts. Detach exhaust downpipes at turbos, noting oxygen sensor positions.

Extracting Turbos and Accessing Oil Lines

Unbolt exhaust manifolds (eight nuts per side, anti-seize recommended)—access requires partial heat shield bending. Lift turbos carefully after coolant line disconnection, catching residuals.

Expose return cover by removing valley debris shields. Unscrew cover bolts (Torx T30), prying gently—inspect for warped surfaces. Disconnect supply lines at turbo inlets using flare nut wrenches to avoid rounding.

Renewing Oil Lines and Associated Seals

Clean mating surfaces meticulously, removing gasket residue. Install new return cover with fresh gasket, torquing bolts crisscross to 10-12 Nm.

Route updated supply lines along OEM paths, securing with clips. Reconnect to turbos with new crush washers, hand-tightening before final torque (18-20 Nm). Refit turbos, aligning precisely to manifolds—use new gaskets and nuts torqued in stages to 25 Nm + 90 degrees.

Reassembling Components and Priming Systems

Reverse disassembly: Reinstall manifolds with fresh gaskets, downpipes, and intakes. Refill oil (BMW LL-01 spec, 8-9 quarts) and coolant (50/50 blue mix).

Prime turbos by disabling fuel and cranking briefly. Reconnect battery, clear adaptations. Idle to temperature, monitoring for leaks—rev gently to circulate.

Managing Potential Hurdles in the Workflow

Seized manifold nuts shear easily—apply heat judiciously. Bent heat shields complicate reassembly; straighten or replace.

Warped return covers demand resurfacing or new units. Line routing errors pinch against hot surfaces, accelerating failure. Incomplete priming starves turbos on startup.

Bolstering Turbo Lubrication Reliability Over Time

Sustained performance hinges on rigorous upkeep. Change oil every 5,000-7,500 miles with approved synthetics to minimize coking.

Inspect lines during services for early weeping. Upgrade to braided stainless lines in tuned applications for heat resistance. Maintain coolant integrity to avoid thermal spikes. Proactive gasket renewals every 100,000 miles avert minor seeps from escalating in these demanding hot-V architectures.

More from BMW

How to fix charge pipe failure on tuned M3/M4

13.12.2025 18:49

How to replace control arm bushings (front thrust arms)

13.12.2025 18:55

How to replace transfer case actuator (xDrive grinding noise)

13.12.2025 14:45

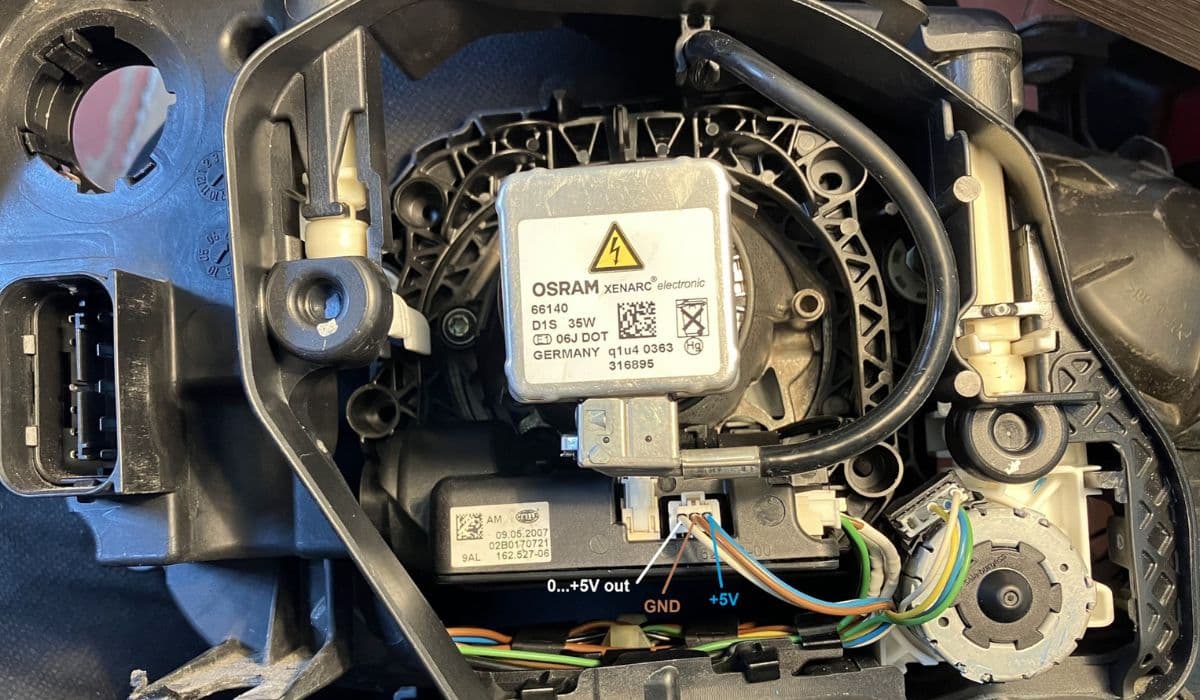

How to fix adaptive headlight malfunction (AHL errors)

13.12.2025 19:00

How to replace IBS battery sensor false errors

13.12.2025 19:06