How to fix wiper motor failure (Tesla Cybertruck)

The Tesla Cybertruck's massive single windshield wiper, often called the "Gigawiper," is one of its most distinctive features, designed to sweep across the expansive angled glass for optimal visibility. However, this innovative system can encounter motor failures, leading to reduced or complete loss of wiper function. Understanding the causes and solutions empowers owners to address the issue effectively and maintain clear sightlines in adverse weather.

Understanding Wiper Motor Failure in the Cybertruck

The Cybertruck's wiper motor is a high-power unit engineered to handle the torque required for the oversized blade. Failures often stem from electrical overstress on the motor controller's gate driver component, causing it to cease operation unexpectedly. This can manifest suddenly, even during light use, and is exacerbated by the system's demand for substantial power to move the long arm.

Other contributing factors include:

Excessive current draw during operation in heavy rain or snow.

Potential misalignment or mechanical strain on the linkage.

Software mismatches that affect motor calibration after repairs.

Owners have reported intermittent issues, such as the wiper stalling mid-swipe or failing to park properly, which can obscure the driver's view and pose safety risks.

Common Symptoms of Wiper Motor Problems

Recognizing early signs allows for timely intervention before complete failure. Pay attention to these indicators:

The wiper blade moves sluggishly or stops partially through a cycle.

No response when activating the wipers via the stalk or touchscreen controls.

Unusual noises from the motor area under the cowl, like grinding or clicking.

The blade fails to return to its parked position, leaving streaks or obstructions.

Inconsistent performance in varying weather, worsening in cold or wet conditions.

These symptoms can appear gradually or abruptly, often linked to the unique demands placed on the motor by the Cybertruck's large windshield.

Initial Troubleshooting Steps

Before escalating to repairs, perform these basic checks to rule out simpler issues:

Inspect the wiper blade for damage, debris, or improper seating on the glass.

Ensure the washer fluid reservoir is filled and nozzles are clear—blocked jets can strain the system.

Cycle the wipers through different speeds using the steering wheel controls.

Check for any software updates via the touchscreen, as over-the-air fixes can resolve calibration glitches.

Gently clean the windshield and blade edges to improve contact and reduce motor load.

These steps often restore functionality temporarily and provide clues about whether the motor itself is at fault.

When to Seek Professional Service

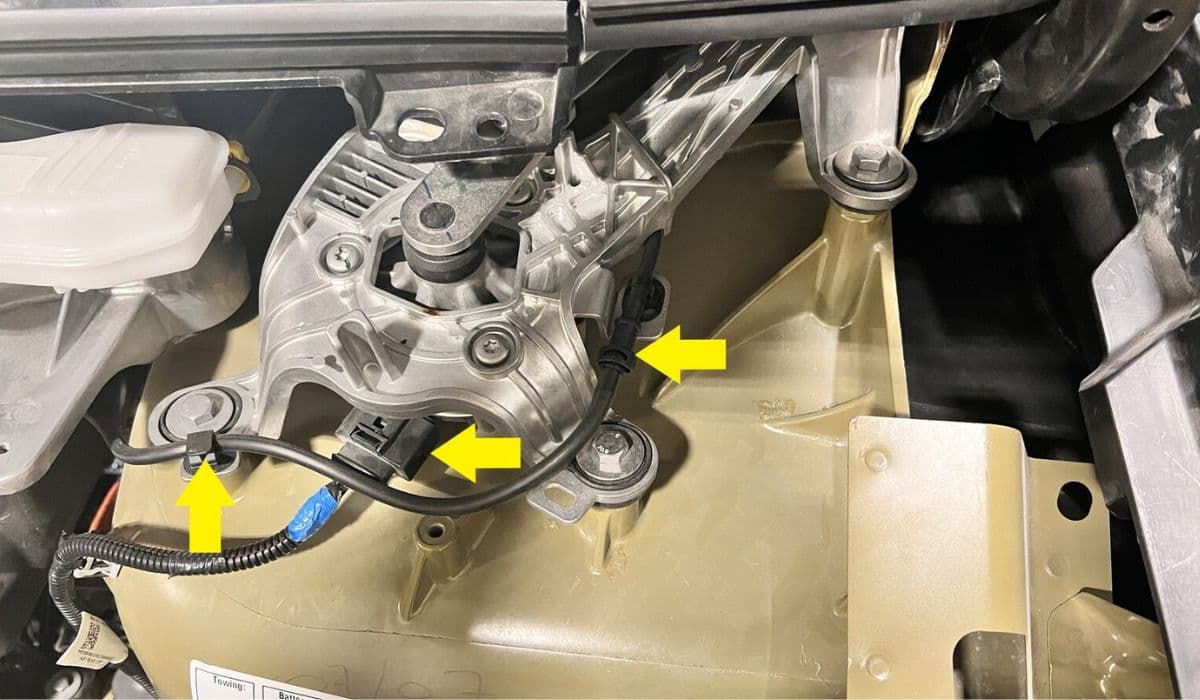

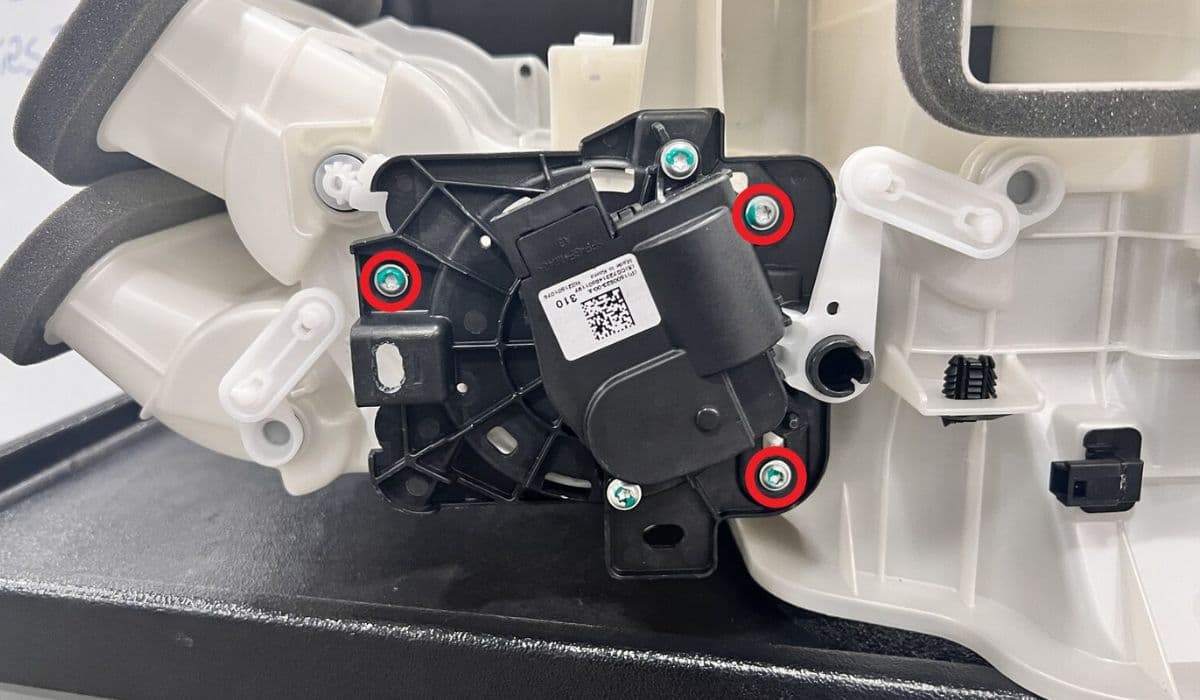

For confirmed motor failures, professional intervention is essential due to the integrated nature of the Cybertruck's systems. Tesla service centers handle these repairs with specialized tools, including:

Diagnostic scans to confirm controller overstress.

Full motor replacement with updated components.

Post-repair software reinstallation to ensure compatibility.

Homing procedures to align the arm precisely, preventing misalignment damage.

Technicians also inspect related components like the linkage and electrical connectors. Ongoing engineering investigations address persistent performance concerns, with some cases involving arm assembly replacements for better pressure and coverage.

DIY Maintenance to Prevent Future Failures

While motor replacement requires expertise, owners can take proactive measures to extend system longevity:

Apply automotive glass treatments to reduce friction and ease blade movement.

Avoid excessive use in dry conditions to minimize unnecessary wear.

Regularly clean the blade and windshield to prevent buildup that increases resistance.

Monitor for proper parking alignment and report anomalies early via the Tesla app.

Use ethanol-based washer fluids suited for varying climates to avoid nozzle clogs.

These habits help mitigate strain on the powerful motor, preserving its performance over time.

Advanced Considerations for Optimal Wiper Performance

The Cybertruck's wiper evolves through iterative improvements, including revised motors and arms for better durability. Owners experiencing reduced clearing efficiency—such as uneven contact or streaking—benefit from service evaluations, where technicians adjust tension or upgrade parts.

In challenging conditions like heavy snow or mud, combining manual controls with auto mode optimizes operation. The system's design prioritizes broad coverage, but real-world feedback drives refinements for even pressure distribution across the vast glass surface.

By staying informed and maintaining the system diligently, Cybertruck owners can ensure reliable visibility, enhancing the vehicle's standout capabilities in any environment.

More from Tesla

How to fix HVAC blend door actuator clicking noise Tesla

16.12.2025 13:16

How to fix FSD visualization lag after Tesla 2025.14 update

16.12.2025 07:02

How to fix phantom drain overnight Tesla

16.12.2025 04:50

How to replace octopus coolant leak (Tesla Model 3 2017–2020)

16.12.2025 03:21

How to replace torn rear seat bolsters Tesla

16.12.2025 03:09