Tesla: How to replace brake calipers (corrosion in salted roads)

Tesla vehicles, with their heavy reliance on regenerative braking, experience far less wear on traditional friction brakes compared to conventional cars. This innovative system recaptures energy during deceleration, extending the life of brake pads and rotors dramatically. However, in regions where roads are treated with salt during winter months, a hidden challenge emerges: corrosion on brake calipers. Salt accelerates rust buildup on sliding pins, pistons, and abutment surfaces, leading to sticking calipers, uneven pad wear, noisy braking, or reduced performance. Ignoring this can compromise safety, making timely intervention essential for Tesla owners in harsh climates.

Understanding Corrosion in Tesla Brake Calipers

Road salt, combined with moisture, creates an aggressive environment for metal components. In Teslas, infrequent use of friction brakes means less heat to evaporate water and burn off contaminants, allowing salt deposits to linger. Over time, this causes:

Seized guide pins that prevent smooth caliper movement

Pitted piston surfaces affecting hydraulic pressure

Corroded abutments leading to pad drag and overheating

Potential for premature rotor warping or vibration during hard stops

Many Tesla owners in northern climates report these issues after several winters, even on low-mileage vehicles. Regular inspection is key—look for rust flakes, sticky pedal feel, or unusual noises when applying brakes manually.

Signs That Your Tesla Brake Calipers Need Attention

Early detection prevents minor corrosion from escalating to full replacement. Common indicators include:

Squealing or grinding sounds unrelated to pad wear

Vehicle pulling to one side during braking

Reduced regenerative braking efficiency (as friction brakes compensate)

Visible rust buildup around caliper edges or slide pins

Brake warning lights or messages on the dashboard

If cleaning and lubrication fail to resolve these, replacement becomes necessary to restore optimal braking dynamics.

Preventive Maintenance to Combat Salt-Induced Corrosion

Tesla recommends annual cleaning and lubrication of brake calipers in salt-belt regions. This simple routine can delay or avoid replacement:

Rinse undercarriage frequently during winter to remove salt

Manually apply brakes periodically to generate heat and dry components

Use high-temperature brake lubricant on pins and contact points during tire rotations

Proactive care keeps calipers sliding freely, preserving the seamless one-pedal driving experience Tesla is known for.

Preparing for Brake Caliper Replacement

Replacing calipers on a Tesla like the Model 3 or Model Y is a manageable DIY task for those with mechanical experience, though professional assistance is advised for novices due to the hydraulic system and electronic parking brake integration. Always prioritize safety.

Essential preparations include:

Parking on a level surface and chocking wheels

Engaging Service Mode via the touchscreen to disable certain systems

Gathering tools: jack stands, torque wrench, brake fluid catcher, and compatible parts

Having fresh brake fluid on hand for bleeding

Work on one corner at a time to avoid mixing components.

Step-by-Step Guide to Replacing Front Brake Calipers

Front calipers on Teslas are floating designs, making access straightforward.

Safely raise and support the vehicle, removing the wheel

Hang the caliper securely to avoid straining the brake line

Disconnect any sensors if present and cap fluid lines to prevent spills

Remove mounting bolts (use new ones for reinstallation)

Carefully lift off the old caliper, inspecting the rotor and pads

Transfer or install new pads if needed, applying anti-seize where appropriate

Mount the new caliper, torquing bolts precisely

Reconnect lines and bleed the system thoroughly

Test pedal feel before driving.

Replacing Rear Brake Calipers on Tesla Models

Rear calipers incorporate the electronic parking brake (EPB), adding complexity.

Enter EPB Service Mode through the vehicle's menu to retract pistons

Disconnect the electrical harness carefully

Follow similar removal steps as the front, but manage the integrated motor

Use a scan tool if required for piston retraction on some models

Install the new unit, ensuring proper harness connection

Bleed brakes and exit Service Mode

Perform a parking brake calibration if prompted

This ensures the EPB functions seamlessly post-replacement.

Post-Replacement Procedures and Testing

After installing new calipers:

Bleed all affected corners to remove air bubbles

Pump the pedal to build pressure

Conduct a low-speed test in a safe area, checking for firm response

Monitor for leaks or warnings over the next few drives

Burnish new components gently for optimal performance

Proper bedding integrates the system, enhancing stopping power.

Long-Term Care for Tesla Brakes in Harsh Conditions

Beyond replacement, adopt habits to minimize future corrosion:

Wash the vehicle regularly, focusing on wheel wells

Apply protective coatings to exposed metal if feasible

Schedule seasonal inspections alongside tire changes

Drive modes that encourage friction brake use occasionally

These steps help maintain the exceptional longevity Tesla brakes are capable of, even in challenging environments.

More from Tesla

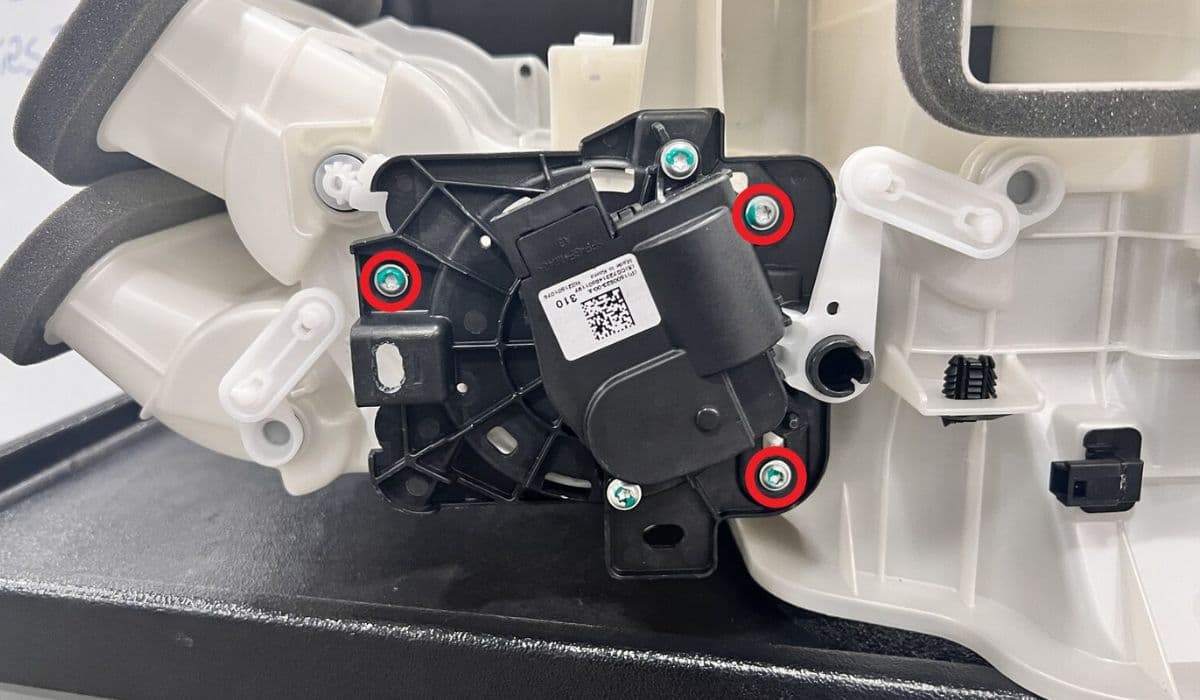

How to fix HVAC blend door actuator clicking noise Tesla

16.12.2025 13:16

How to fix FSD visualization lag after Tesla 2025.14 update

16.12.2025 07:02

How to fix phantom drain overnight Tesla

16.12.2025 04:50

How to replace octopus coolant leak (Tesla Model 3 2017–2020)

16.12.2025 03:21

How to replace torn rear seat bolsters Tesla

16.12.2025 03:09