Tesla: How to replace drive unit whining bearings

Tesla electric vehicles are renowned for their silent operation and powerful performance, but over time, some owners encounter a distinctive whining or milling noise from the drive unit. This sound, often described as a high-pitched hum that varies with speed, typically stems from worn bearings within the drive unit assembly. Addressing this issue can restore the smooth, quiet drive that Tesla owners expect, transforming an annoying vibration into seamless acceleration.

Understanding the Drive Unit Whining Noise

The drive unit in Tesla models integrates the electric motor, inverter, and reduction gears into a compact powerhouse. Bearings support the rotor and pinion shafts, ensuring smooth rotation under high torque loads. When these bearings degrade, they produce a characteristic whine—distinct from the normal electric motor hum—that intensifies during acceleration or at certain speeds.

Common triggers include:

Electrical arcing from shaft currents in older designs

Coolant seal failures allowing contamination

Natural wear from mileage and regenerative braking stresses

Insufficient lubrication or preload issues

This noise differs from wheel bearing failures, which often change with turns or load shifts. Drive unit bearing whine remains consistent regardless of steering input and persists coasting or under light throttle.

Early detection is key. The sound starts subtle but grows louder, potentially leading to reduced efficiency or further component damage if ignored.

Diagnosing Bearing Issues in the Drive Unit

Accurate diagnosis prevents unnecessary repairs. Start with a thorough test drive to isolate the source.

Key diagnostic steps:

Listen for noise changes with acceleration, deceleration, and coasting

Note if the whine is speed-dependent but not load-sensitive in turns

Compare front and rear in dual-motor models—rear units are more commonly affected in certain configurations

Use chassis ears or a mechanic's stethoscope for precise location

Check for accompanying vibrations felt through the seat or floor

In many cases, the whine originates from the rotor bearings supporting the motor shaft. Advanced tools like vibration analyzers can confirm bearing frequencies, but owner reports and service experience often suffice.

Rule out alternatives:

Tire noise (changes with road surface)

Inverter hum (constant pitch)

Suspension components (affected by bumps)

Professional verification ensures the drive unit is the culprit before proceeding.

Preparing for Bearing Replacement

Replacing drive unit bearings is an advanced repair requiring mechanical expertise, specialized tools, and a clean workspace. It's not a beginner DIY but feasible for experienced enthusiasts with access to parts.

Essential preparations:

Secure hybrid ceramic bearings (e.g., SKF variants resistant to electrical damage)

Obtain compatible seals for coolant and oil barriers

Gather tools: bearing pullers, presses, torque wrenches, and locknut sockets

Drain drive unit oil and coolant beforehand

Work in a level, well-ventilated area with proper lifting equipment

Safety first: Disconnect the high-voltage battery and follow isolation procedures. The drive unit is heavy—use an engine hoist or transmission jack for removal.

This repair extends drive unit life significantly, avoiding full assembly swaps.

Step-by-Step Drive Unit Removal

Begin by safely accessing the affected drive unit—typically rear in single-motor setups.

Removal process:

Elevate the vehicle and support on stands

Remove the wheel and halfshaft nut

Disconnect suspension links and brake components

Drain fluids from the unit

Unbolt mounts and electrical connectors

Carefully lower the subframe if needed for clearance

For dual-motor vehicles, identify whether front or rear is noisy. Rear units are more accessible in many models.

Mark all connections for reassembly. Inspect halfshafts and mounts during removal for secondary issues.

Disassembling the Drive Unit

With the unit on a workbench, disassembly reveals the bearings.

Core steps:

Separate the inverter and motor housing

Remove the rotor by supporting and gently dropping or pressing

Access pinion and rotor bearings

Clean away old grease and inspect for contamination

Common findings include fretting on races or coolant ingress grooves. Hybrid ceramic upgrades prevent recurring electrical pitting.

Use heat judiciously for stuck components, avoiding damage to windings.

Replacing the Whining Bearings

The heart of the repair: installing fresh bearings.

Procedure highlights:

Press out old bearings with appropriate pullers

Clean bores thoroughly

Apply retaining compound where specified

Install new hybrid ceramic bearings with precise preload

Replace seals to prevent future leaks

Preload is critical—use disc springs or shims as per design. Torque locknuts accurately with thread locker.

Rotor bearings often 6007 size

Pinion bearing may differ (e.g., 6208)

Gearbox seal upgrades improve longevity

Reassembly mirrors disassembly, ensuring alignment.

Reinstallation and Testing

Refit the refreshed drive unit.

Final steps:

Refill with specified synthetic oil

Reconnect all components with proper torques

Bleed coolant if disturbed

Perform a controlled test drive monitoring for noise

Break-in gently, listening for improvements. The whine should vanish, leaving only the signature Tesla silence.

This meticulous process not only eliminates the annoying sound but enhances overall drivetrain durability.

More from Tesla

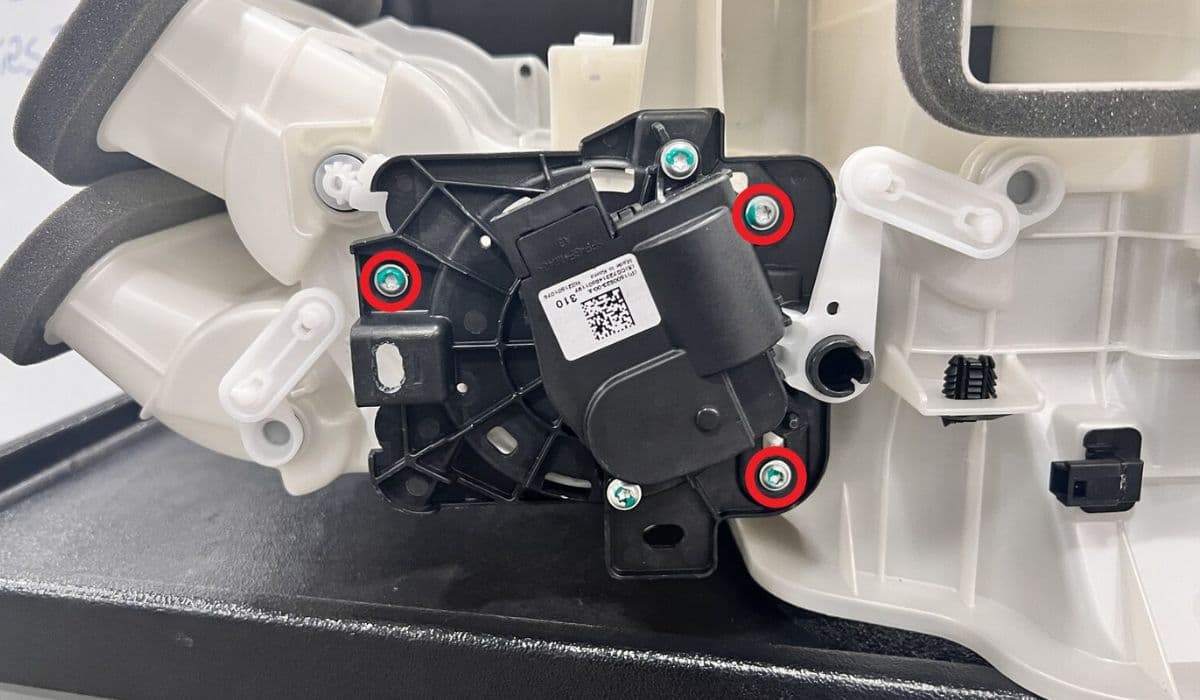

How to fix HVAC blend door actuator clicking noise Tesla

16.12.2025 13:16

How to fix FSD visualization lag after Tesla 2025.14 update

16.12.2025 07:02

How to fix phantom drain overnight Tesla

16.12.2025 04:50

How to replace octopus coolant leak (Tesla Model 3 2017–2020)

16.12.2025 03:21

How to replace torn rear seat bolsters Tesla

16.12.2025 03:09