Tesla Model Y: Top reliability but endless suspension complaints

The Tesla Model Y has solidified its position as one of the most dependable electric SUVs on the market, consistently earning praise for its powertrain durability, minimal maintenance needs, and impressive long-term ownership satisfaction. While many EVs struggle with complex battery management or drivetrain failures, the Model Y stands out with remarkably low rates of major mechanical breakdowns. Owners frequently report driving hundreds of thousands of miles with little more than tire rotations and software updates. This core reliability stems from Tesla's simplified electric architecture—no oil changes, no transmission issues, and regenerative braking that extends brake life dramatically.

Yet, beneath this impressive dependability lies a persistent thorn: suspension complaints that seem never-ending. Forums, owner groups, and service records are filled with stories of creaks, groans, rattles, and knocks emanating from the chassis, often starting as early as the first few thousand miles. This paradox—bulletproof drivetrain paired with a noisy, sometimes harsh ride—has become the defining quirk of the Model Y experience.

What Makes the Model Y So Reliable Overall

At its heart, the Model Y benefits from Tesla's mature electric platform shared with the Model 3. The dual-motor or single-motor setups deliver instant torque without the wear and tear of traditional gearboxes. Battery packs hold up exceptionally well, with degradation often under 10% after years of heavy use.

Key reliability strengths include:

Virtually zero unscheduled repairs for the electric motors or high-voltage system in most cases.

Brakes that last extraordinarily long due to one-pedal driving.

Over-the-air updates that fix software glitches remotely, preventing many minor issues from escalating.

Structural integrity that shines in real-world crash tests and daily abuse.

Low ownership costs when avoiding body or suspension work.

Independent surveys from organizations like J.D. Power highlight the Model Y scoring above average in quality and dependability for critical components. Many owners describe it as the most trouble-free vehicle they've owned, especially compared to luxury ICE SUVs plagued by engine or transmission failures.

The Suspension Paradox: Why Complaints Persist

Despite the glowing powertrain reports, suspension feedback tells a different story. The Model Y's setup prioritizes sharp handling and low center of gravity for an EV of its size, resulting in a firm tune that excels on smooth roads but punishes imperfections. High vehicle weight combined with instant torque acceleration stresses components in ways gasoline vehicles rarely experience.

Common suspension-related grievances dominate owner discussions:

Creaking or groaning from front upper control arms during low-speed turns.

Rattling over bumps, often traced to bushings in lower links.

Harsh impacts from potholes that reverberate through the cabin.

Premature wear on ball joints, leading to noises that return even after repairs.

A ride quality described as "truck-like" or overly stiff by those expecting luxury comfort.

These issues aren't catastrophic failures that strand drivers, but they erode the premium feel Tesla aims for. Water ingress into joints, torque twist under acceleration, and aggressive damping all contribute to the symphony of sounds that frustrinate perfectionists.

Real Owner Experiences: From Bliss to Frustration

Thousands of Model Y drivers rave about crossing continents without a single breakdown, charging seamlessly on road trips, and enjoying silent acceleration that spoils all other cars. One owner might boast of flawless performance after 150,000 miles, while another in the same forum laments constant service visits for noises that techs struggle to replicate.

The split often comes down to expectations and road conditions. Sporty drivers embrace the taut setup for cornering prowess, while families hauling kids over urban potholes find it exhausting. Interestingly, vehicles from certain factories show fewer complaints, hinting at production variations that Tesla continually refines.

How Tesla Addresses and Owners Mitigate Issues

Tesla has iterated on suspension tuning multiple times, introducing "comfort" variants with softer dampers and revised bushings that significantly reduce harshness and noise. Service bulletins cover many common fixes under warranty, including control arm replacements that resolve creaks for good in some cases.

Enthusiasts turn to aftermarket solutions for lasting relief:

Upgraded bushings from specialists that handle torque better.

Coilover kits for adjustable comfort without sacrificing handling.

Simple grease injections as temporary bandaids for dry joints.

Alignment tweaks to prevent uneven tire wear from stiff geometry.

These modifications transform the ride, turning complainers into evangelists who argue the stock setup is the only real flaw in an otherwise brilliant package.

The Bigger Picture: Is It a Deal-Breaker?

The Model Y's suspension woes highlight the challenges of building a high-performance EV at scale. Heavy batteries demand robust yet responsive chassis, and Tesla's aggressive development pace means some compromises ship to customers. Competitors with softer tunes might feel plusher initially, but few match the Model Y's efficiency, range consistency, or sheer driving joy on a twisty road.

For many, the endless complaints are just that—noise in an otherwise silent electric masterpiece. The core reliability remains top-tier, with suspension quirks serving as a reminder that perfection is iterative. As refinements continue, the Model Y keeps proving why it dominates sales: it delivers more thrills and fewer headaches than almost anything else on the road.

More from Tesla

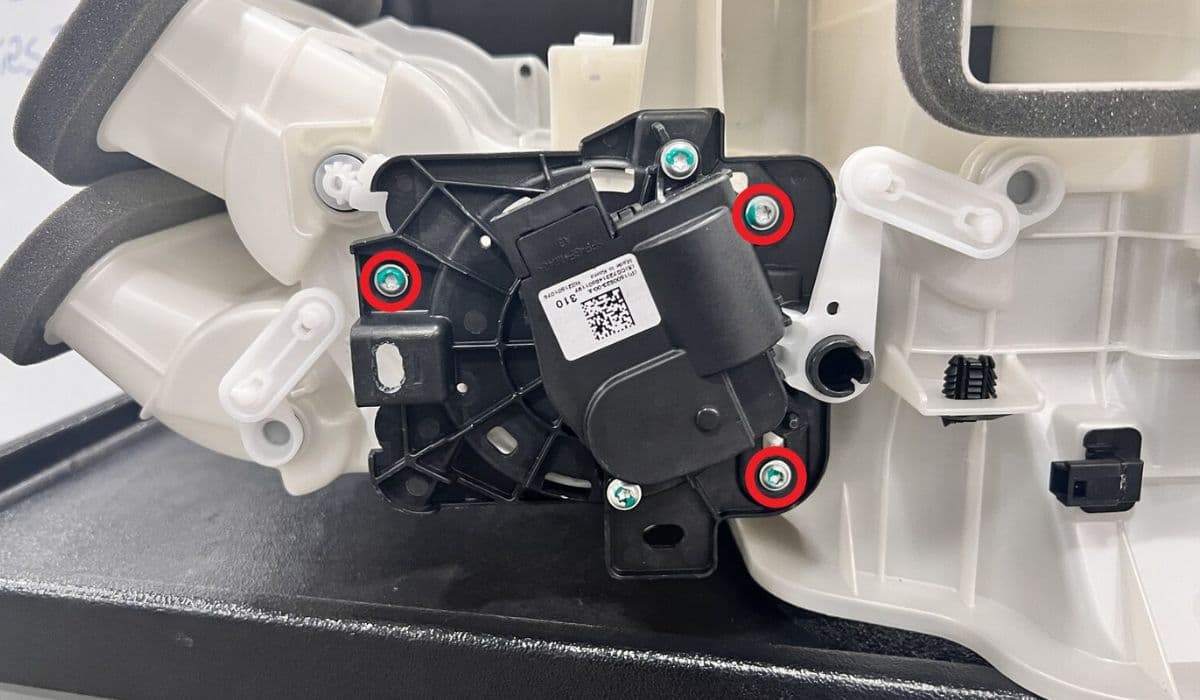

How to fix HVAC blend door actuator clicking noise Tesla

16.12.2025 13:16

How to fix FSD visualization lag after Tesla 2025.14 update

16.12.2025 07:02

How to fix phantom drain overnight Tesla

16.12.2025 04:50

How to replace octopus coolant leak (Tesla Model 3 2017–2020)

16.12.2025 03:21

How to replace torn rear seat bolsters Tesla

16.12.2025 03:09